|

|

|

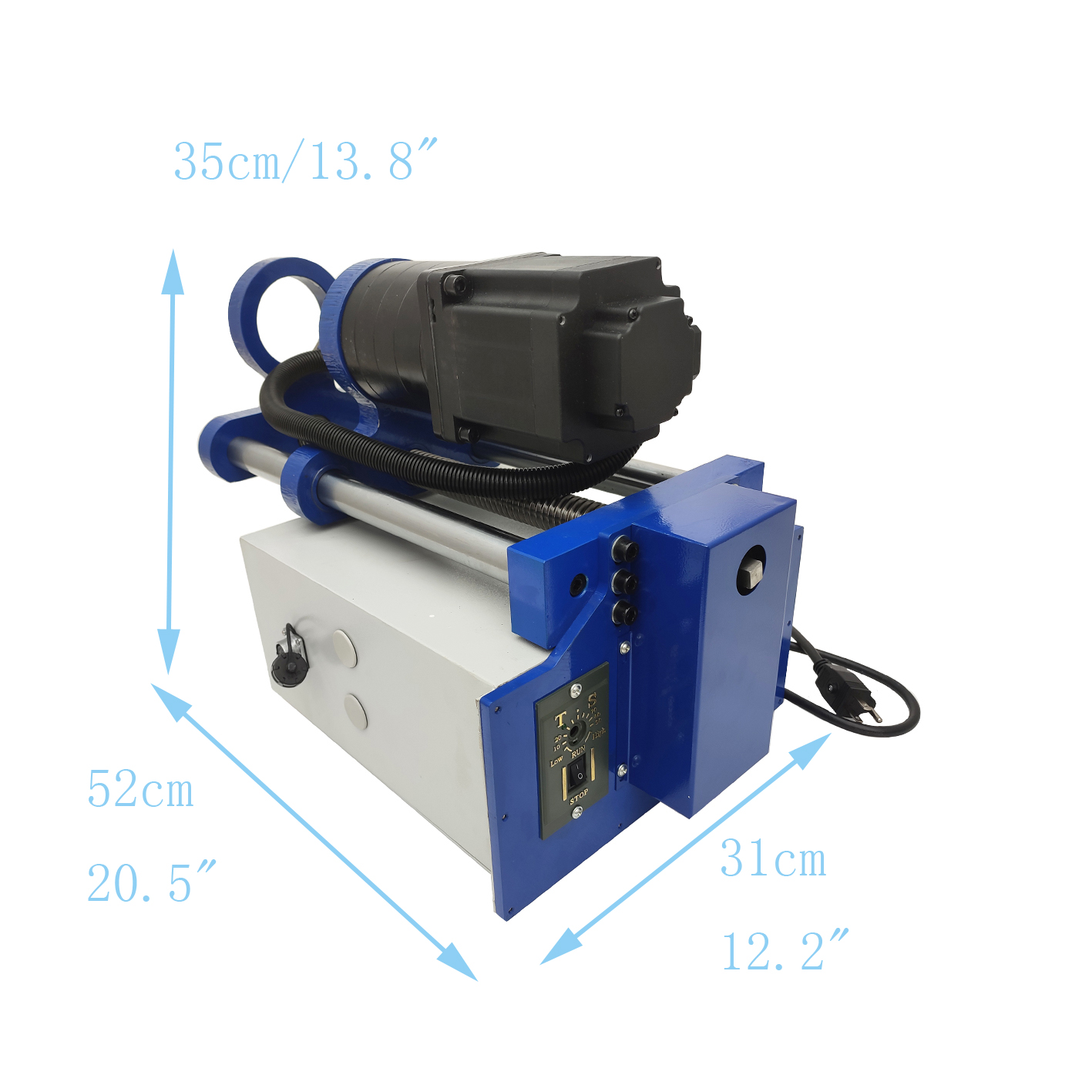

Hole Drilling Machine for Engineering Machinery(110V,LT-30-2)

|

|

|

|

|

|

|

|

Hole

drilling machine for engineering machinery

is a piece of portable

processing equipment developed for field service of engineering

machinery, and is mainly used for processing inner holes and

concentric span holes of small-scale pipelines, and widely

applied in engineering machinery including excavators,

cranes, loaders and hoists. Only one person is required for operation, and the actual operation

difficulty is greatly reduced for its focus on field in design concept

and processing to make a serviceman operate the machine

easily.

Main

application scope: processing after repair welding, or

bushing installation after hole expansion of rotation holes,

hinge joint holes and hinge pin holes,

and hinge pin hole in all engineering machines; repair and

processing of concentric holes in excavators,

loaders, pressure machines, cranes, etc.; and side-by-side

arrangement of multiple holes to conduct one-time

positioning processing to ensure the Coaxiality of these

holes.

|

|

Product features

|

|

1 Driving

of hole drilling machine.By

adopting 110V AC servo motor with characteristics of low-speed

revolution and high torque, the complete machine can realize

stationary machining in superior performance.

2 No vibration in end travel and cutting process.

3 Feeding and processing can realize

electrodeless speed

regulation. Feeding process can be set according to demands, and processing can

automatically stop after reaching the limit switch.

|

|

|

4 Boring bar adopting high-strength alloy and structural

steel with characteristics of high hardness, high accuracy, high tenacity, good

abrasion resistance, etc.

5 In effective travel, the tool rest can be fixed at any position of

boring bar.

6 The boring bar can be disassembled separately

and assembled.

|

|

|

7 Electric motor controller is equipped with

an immediate brake program to Avoid vibration in

the shutdown process . |

|

|

8 The control Cabinet is installed below the main engine to be

beneficial to safety operation.

|

|

|

Operation Instructions |

|

1.The

operator should accept safety education and operation

training, and have machining experience.Work clothes have to

be worn before operating the machine.

2.Check

if the connected power voltage is consistent with the

voltage required in the nameplate before starting up.Check

if the card mount system has been locked before starting up.

3.Pull

the workpiece in alignment, or align the workpiece at the

minimum speed. Alignment at high speed is not allowed.

4.Do not

put hand or other things close to the equipment before

starting up so as to avoid the personal injury. Electric

wire should be far away from the place with high

temperature, oil or sharp edge.

5.Turn

off the power by remote control when failure or abnormal

sound occurs before inspection and repair.Do not operate the

machine in unattended condition. Personal can only leave the

site after confirming that the drive system is at the

neutral position and the power is turned off when the

machine stops operation.

6.It is

strictly prohibited to use this machine in processing range

exceeding or lower than the noted range. The machine should

not exceed the regulated maximum cutting capacity to avoid

damage and personal injury caused by the machine.

7.It is

strictly prohibited to directly change the feeding direction

after the machine operates.

8.After

processing, oil and filings on the machine should be

removed, and Slushing oil should be sprayed on the tool arm

and spindle.

|

|

Operation Process |

|

1.Fixed seat

can be installed in position for allowing workpiece welding.

Push the boring bar into the hole requiring processing with

nylon locating taper sleeve, and lock the locating boring bar

with tool rests on both sides to ensure the concentricity of two

holes locating taper sleeve boring bar locating taper sleeve.Fit

supports into boring bar, and weld these two supports in

appropriate position of workpiece.Take off the locating taper

sleeve (please ensure that the boring bar can rotate and slip

axially freely).

2.Installation of main body:Fit

the main body into support.

3.The

power voltage should be 110V, and insert the plug of electricity

box into the 110V power.

4.Put the

tool rest into bar-type slot of boring bar, and fix it with

compression screw.Cutting depth for one side should be 0.2-l.0mm

in trial cutting.

5.Please

rationally arrange the feed amount according to the size in

cutting by adjusting the feed button from zero slowly in general

range. The adjustment should not be too fast, or damage may

occur for fast feeding.Please select rational tool and tool

angle in processing (the angle can be the tool angle of boring

cutter). |

|

Parameter

|

The maximum processing hole diameter:

80mm

The minimum processing hole diameter: 35mm

The maximum processing travel: 300mm

The maximum feed depth: 3mm on one side (A3 steel)

Surface roughness: Ra3.2

Deviation from circular form<0.02mm

Gross weight of equipment: 98KG

Power supply: 110V60Hz

Voltage: 1500W

Boring bar length: 1600mm

Diameter: 30mm

|

|

|

|

|

|

Packaging List

|

Host * 1

Remote control * 1

Boring bar * 1

Centering cone * 2

Knife holder * 1

Knife disc * 1

Bracket * 2

Support bolt * 8

Support bolt and nut * 16

Knife handle * 1

Blade * 2

White steel knife * 1

Wrench * 1

One set of hexagonal wrenches

Spare screws * 1 pack

|

|

Item Number: 022780

|

|

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.

|

|