|

|

|

110V

Automatic Double-sided Gluing Machine Glue Coating Machine for Paper &

Leather |

|

|

|

|

|

|

|

|

Product

Overview |

|

The automatic double-sided gluing machine is

an efficient and professional device for coating the double sides of

paper products, leather, thin workpieces and other objects with

water-soluble glue evenly simultaneously and continuously. It is

equipped with a high-quality soft roller to achieve more uniform gluing

operation. The gluing machine has the advantages of uniform coating, gap

adjustability, speed controllability, high working efficiency and so on.

The automatic double-sided gluing machine can be widely applied to the

industries of artware and model making, packaging, building decoration,

shoe production, etc. |

|

Product

Parameters |

|

Voltage |

AC110V 60Hz |

|

Power |

200W |

|

Coating Speed |

0-16m/min |

|

Coating Width |

15.35" (390mm) |

|

Material Thickness |

0.004"-0.59" (0.1-15mm) |

|

Product Size |

33.07"×11.02"×20.87" (84×28×53cm) |

|

Net weight |

56kg (123.46LBS) |

|

|

|

Product

Features |

|

|

1.

High working efficiency, the 200W motor, low noise and energy

consumption, achieves fast start and stop through one switch.

2.

Better double-sided gluing effect, uses a soft roller with the gluing

width of 15.35in, high elasticity, better coat uneven materials with

water latex.

3.

Large capacity, hold more glue with a glue box on the top, convenient to

control through the control valve, easy to clean, resistant to

corrosion. Also supply glue with the glue tray at the bottom, and

facilitate double-sided gluing.

4.

Excellent adjustability, two product thickness adjusting knobs for

flexibly adjusting the gluing rollers to adapt to different materials,

and four gluing thickness adjusting knobs for flexibly adjusting the

roller gap to meet the gluing thickness demands.

5.

Speed Adjustability, the speed regulator for easily adjusting the gluing

speed as needed.

6.

Good safety protection function, a motor safety baffle for improving

safety and preventing accidents.

7.

Wide application fields, suitable for gluing various materials such as

paper and leather in different industrial fields. |

|

|

|

High-Quality Motor

The 200W high-quality motor provides the enough driving power

for glue coating operation, remarkably improving the production

efficiency, obviously reducing the energy consumption and noise

and effectively achieving high precision control and stable

running. It is quickly started and stopped through one switch,

and gives a quick response to the instruction.

|

|

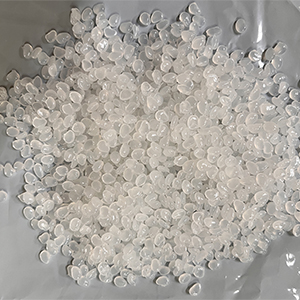

Soft Roller

Compared with a traditional gluing machine, the automatic gluing

machine has the advantage that a soft roller is adopted instead

of a steel roller. The coating width can be 15.35in/390cm. The

soft roller has good properties such as good elasticity, good

coating uniformity and better gluing effect. The soft roller is

more suitable for coating the uneven material surfaces.

|

|

Glue Box & Glue Tray

The top glue box and the bottom glue tray are adopted to provide

water-soluble glue from the top and bottom correspondingly, well

achieving double-sided gluing operation. The glue box on the top

can hold large amount of glue and uses a control valve to adjust

the glue flow, ensuring good sealing performance and

controllability.

|

|

|

|

|

Speed

Regulator

The speed regulator is of a knob structure, easily and

accurately adjusting the gluing speed to meet the requirements

of different materials and further improving the gluing effect.

The structure is simple, and the practicability and reliability

is higher.

|

|

Gap

Adjusting Knobs

Four adjusting knobs on the front side are specially designed

for adjusting the gap between the rollers so as to adjust the

gluing thickness according to the user’s demand. When the knobs

are adjusted properly, glue can be closely attached to the soft

roller and then adhere to different materials along with

relative rotation of the rollers.

|

|

Supporting

Leg

The rubber supporting legs have a stable and reliable supporting

effect on the machine, effectively reducing the vibration of the

machine during use, preventing the machine from movement and

keeping the machine balanced and stable.

|

|

|

Attention |

|

1. In

the working process, do not touch the rollers so as to prevent hands

from being crushed. |

|

2. Please note that the voltage of the gluing machine

is 110V 60Hz. |

|

3. Use glue that meets the requirements

of the machine. Avoid using glue with strong corrosiveness or

inconsistent with the viscosity requirements to avoid damaging machine

components. |

|

4. Each time the work is completed, please wipe away

the glue on the machine to prolong the service life of the machine. |

|

5. After the work

is completed every day, each sleeve should be lubricated timely, then

idling needs to be conducted for a few minutes, and then the machine can

be stopped. |

|

Operation Method |

|

1. Preparation

(1) Place the machine on a flat and stable

workbench, and adjust the bottom support feet to keep the

machine horizontal.

(2) Open the lid of the glue storage device

and pour an appropriate amount of glue into it. Be careful not

to exceed the maximum scale line.

2. Parameter Setting

According to the thickness of the material to

be glued and the required glue coating amount, adjust the roller

gap through the adjustment knobs on both sides of the roller

group.

3. Start-up Operation

(1) Connect the power supply, press the start

switch on the right control box, and observe whether the glue

spreading roller group operates normally.

(2) Slowly feed the to-be-glued material from

one end of the glue spreading roller group to ensure that the

material passes through the roller group smoothly.

4. Monitoring in the Gluing Process

In the gluing process, pay attention to the

gluing situation. If problems such as uneven gluing occur, the

glue outflow can be fine-tuned through the control valve below

the glue storage device, or the roller gap can be adjusted.

5. Shutdown and Cleaning

(1) After the gluing work is completed, press

the stop switch and turn off the power.

(2) Clean the glue storage device, glue

spreading roller group and other components in a timely manner

to prevent the glue from drying and affecting the next use.

Special cleaning agents and tools can be used for cleaning

according to the cleaning method in the manual. |

|

|

Product

Display |

|

|

|

|

|

Item Number (120124):

1 x Automatic Double-sided Gluing Machine 110V |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|