|

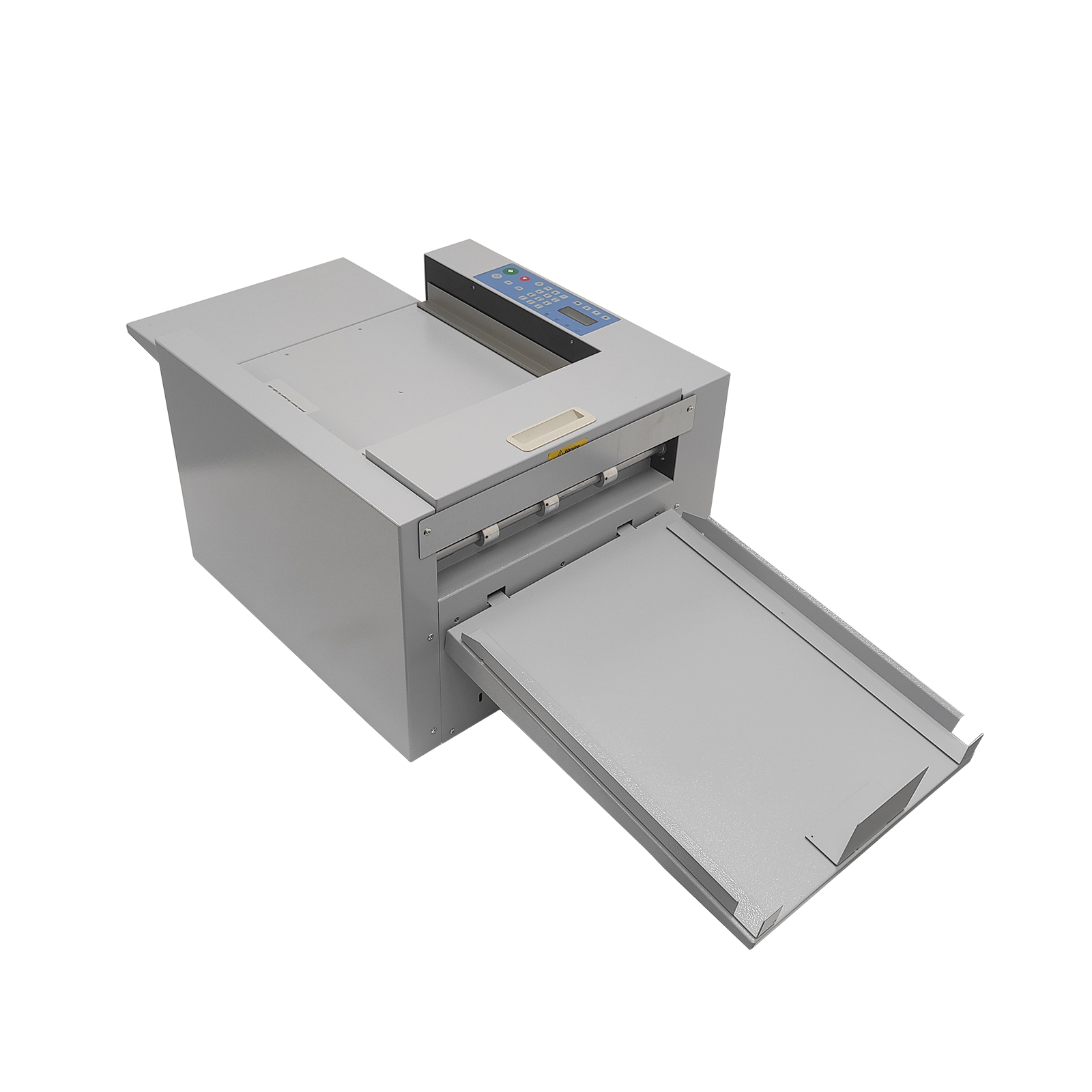

330mm 13'' Digital

Electric Creasing and Perforating Machine 110V |

|

|

|

|

|

|

|

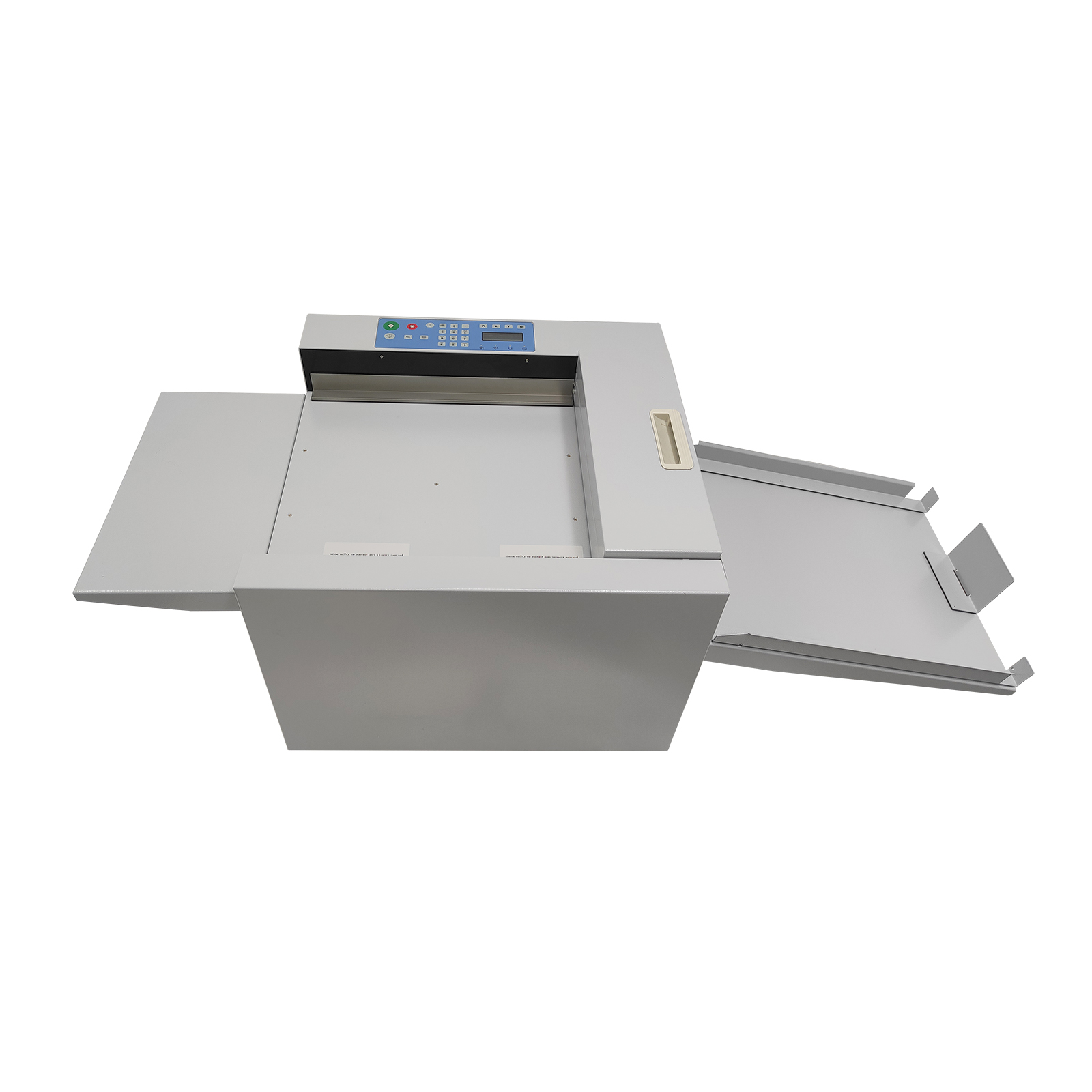

The 330mm digital electric

creasing and perforating machine is designed for creasing and

perforating various paper sheets such as coated paper, laminated paper

and other sheets, combines the creasing function and the perforating

function into a whole, can process perfect creases and dotted lines, is

easy to operate, convenient to use, low in consumption and high in

efficiency, and can be widely applied to printing houses, packing

houses, office buildings and other occasions. |

|

|

Product

Parameters |

|

Maximum Paper Size: 330x900mm |

|

Minimum Paper Size: 50x90mm |

|

Paper Thickness: 100-350g/m²

(creasing), 100-200g/m² (perforating) |

|

Paper Type: coated paper,

laminated paper, varnish paper etc. |

|

Working Precision: +/-0.3mm |

|

Working Speed: 2600 pages/hour

(one crease on each A4 paper) |

|

Creasing Times in Each Paper: 0-32

times |

|

Voltage: 110V 60Hz |

|

Power: 150W |

|

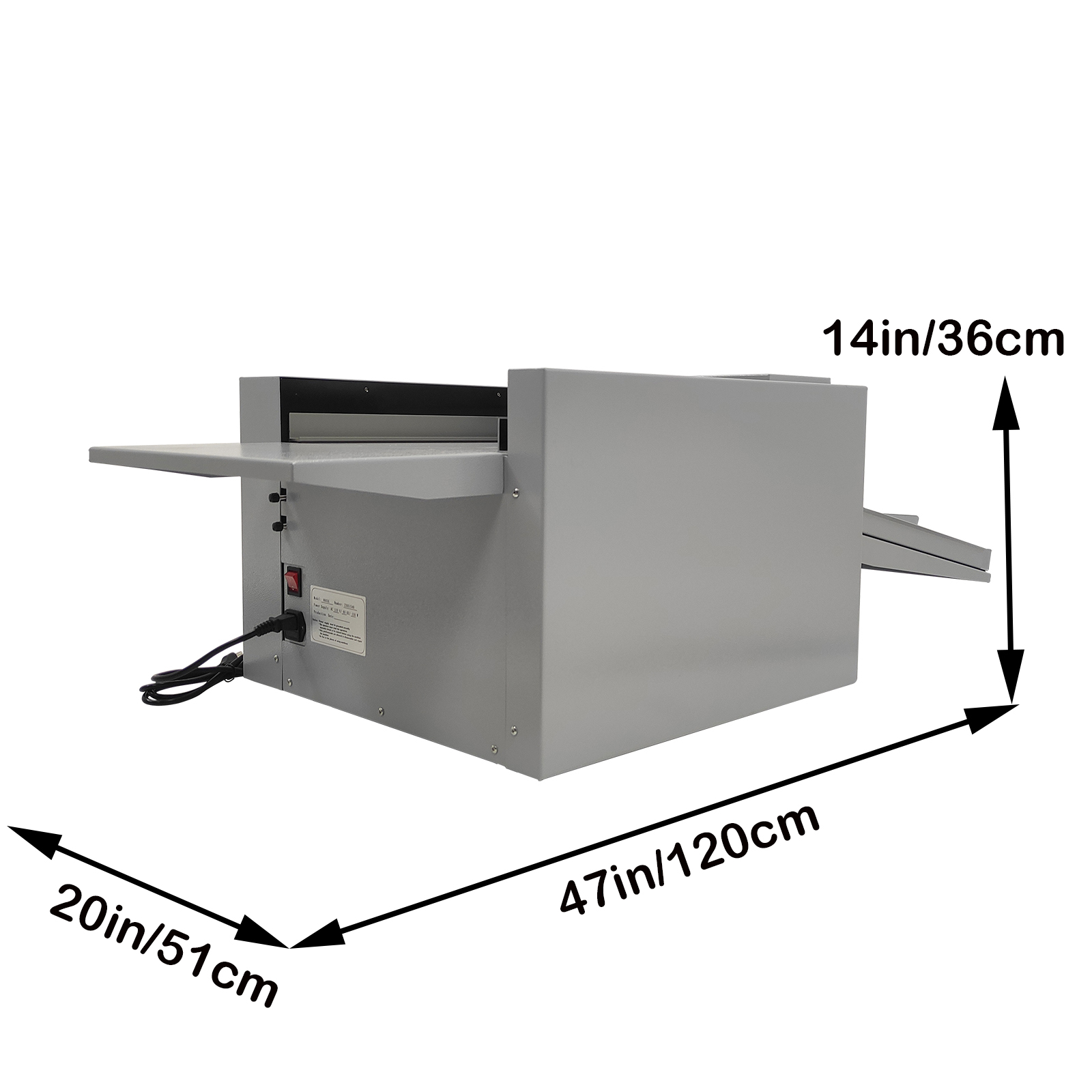

Machine Size: 120x51x36cm

(47''x20''x14'') |

|

Tools: one transverse creasing

tool set and one transverse perforating tool set |

|

|

Product

Features |

|

Suitable for different paper

types: The creasing and

perforating machine can process different paper sheets such as coated

paper, laminated paper, varnish paper, and is broad in application range

and high in practicability. |

|

|

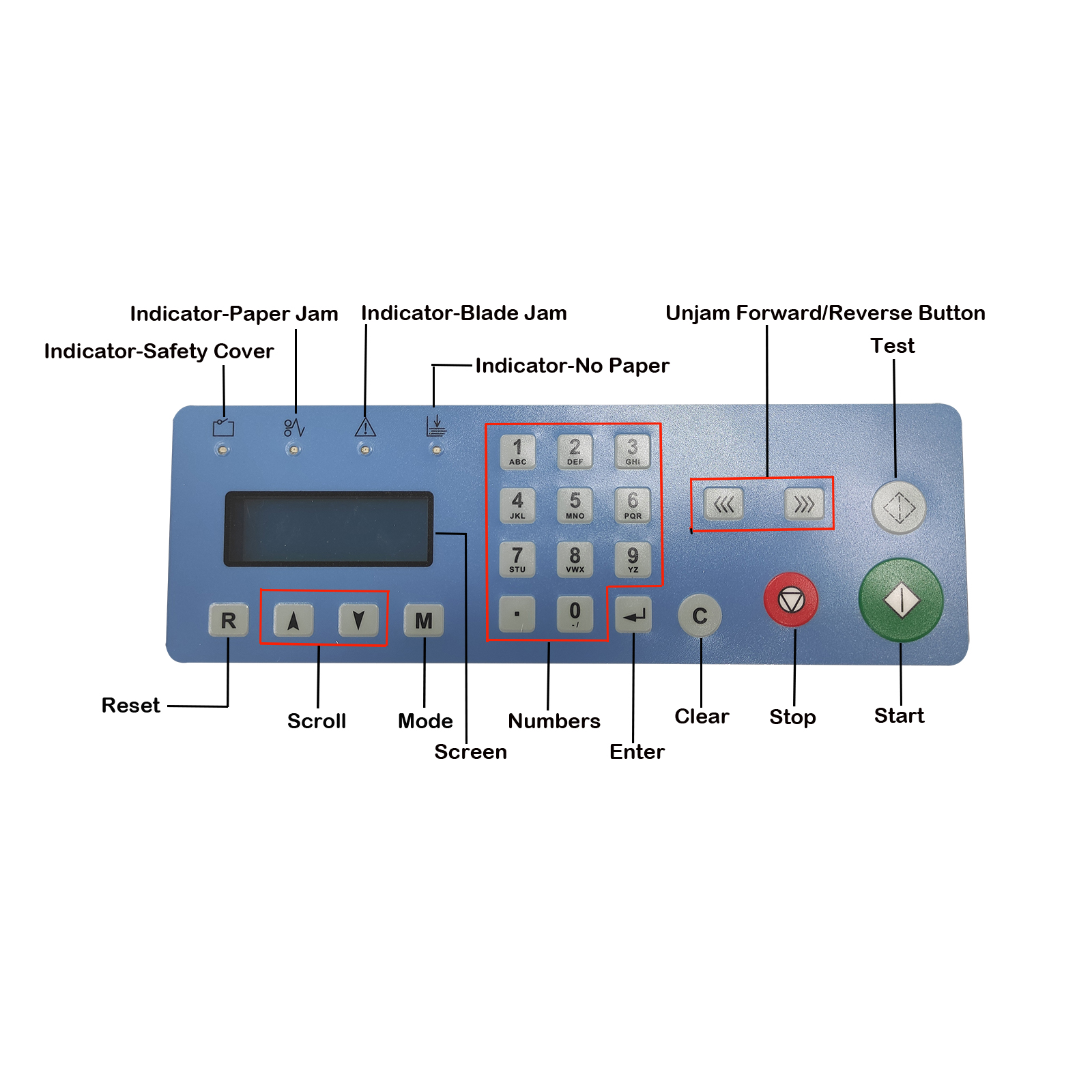

Intelligent control:

The digital intelligent control

panel is designed on the top of the machine, the user can easily control

the machine to work through the control panel, various faults can be

clealy shown by the indicators on the control panel, and the machine is

easy to control and high in performance. |

|

Multiple in function:

The creasing function and the

perforating function are combined into a whole, the perfect creases and

dotted lines can be quickly formed by the transverse creasing tool set

and the transverse perforating tool set in a short period, and the user

can choose the tool sets to achieve different effects as required.

|

|

|

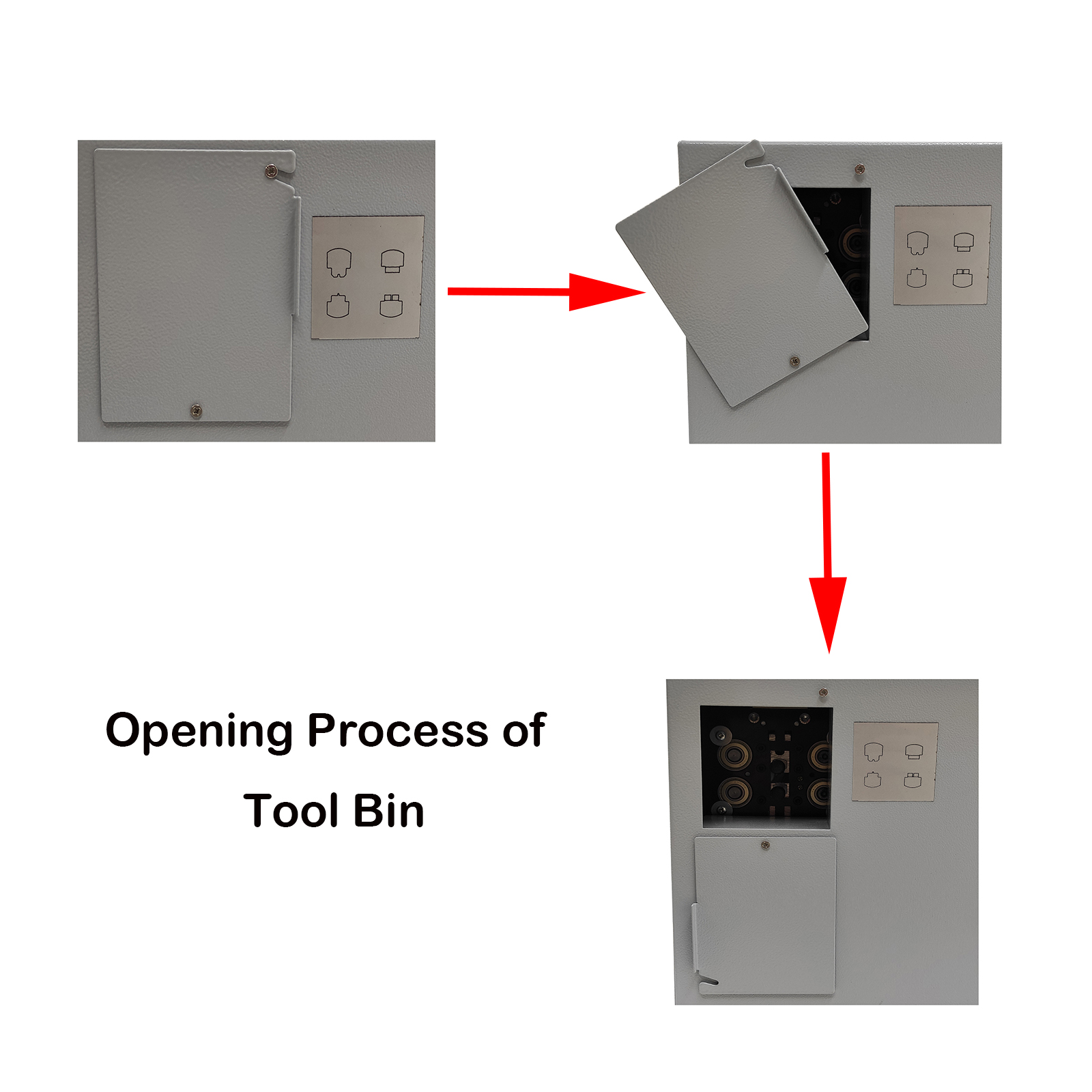

Convenient to replace and store

tools: The creasing tool

set and the perforating tool set can be easily drawn out of the tool set

installation bin and replaced with each other as needed, the replaced

tool set can be well stored in the standby tool set storage position,

and convenience is greatly improved. |

|

Adjustable in pressure:

The pressure of the rollers can be

easily adjusted according to the paper thickness, the user can

conveniently adjust the pressure adjusting holes through a hex wrench

before creasing and perforating operation is conducted, and the

practicability and the user experience can be greatly improved. |

|

|

Easy to dissipate heat:

The heat dissipation holes are

formed in the side face of the creasing machine, the heat generated by

the machine can quickly dissipate through the heat dissipation holes,

normal running of the machine can be well guaranteed, and the service

life of the machine can be prolonged. |

|

Convenient to feed and discharge

paper: A large feeding

table and a long extension table are installed on the front side and the

rear side of the machine, paper can be easily and quickly fed and

discharged in the operating process, and the processed paper can be well

collected and stored. |

|

|

The effects of

creasing and perforating |

|

|

Operation

Method |

|

1. The feeding table and the

extension table are installed and fixed on the two sides of the machine

through holes and screws respectively. |

|

2. The machine is connected to the

110V power supply, the power switch is pressed, and the machine will do

self-test operation and then jump to the operation mode automatically. |

|

3. The user inputs different data

to achieve different creasing and perforating effects through the

control panel according to the operation manual. |

|

4. The user can choose different

tool sets to form creases and dotted lines as required and replace the

tool sets after the machine stops. |

|

|

|

Notes: |

|

1. Check the plug

and machine voltage and frequency to your 110V main supply, and that the

socket has a correct working earth lead for this single insulated

machine. |

|

2. Don't touch any

running parts while running. |

|

3. Don't shut down

the machine while running. |

|

|

|

Item Number (122157): 1 x 330mm 13''

Digital Electric Creasing and Perforating Machine |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |