|

|

|

Automatic Saw Blade Grinding Machine 220V |

|

|

|

|

|

|

|

| Features |

| This machine is a fully automatic gear grinding machine designed according to the grinding of circular saw blades. parameterThe machine has the advantages of simple structure, convenient operation, complete functions, high efficiency and energy saving, low carbon environmental protection and accurate grinding. |

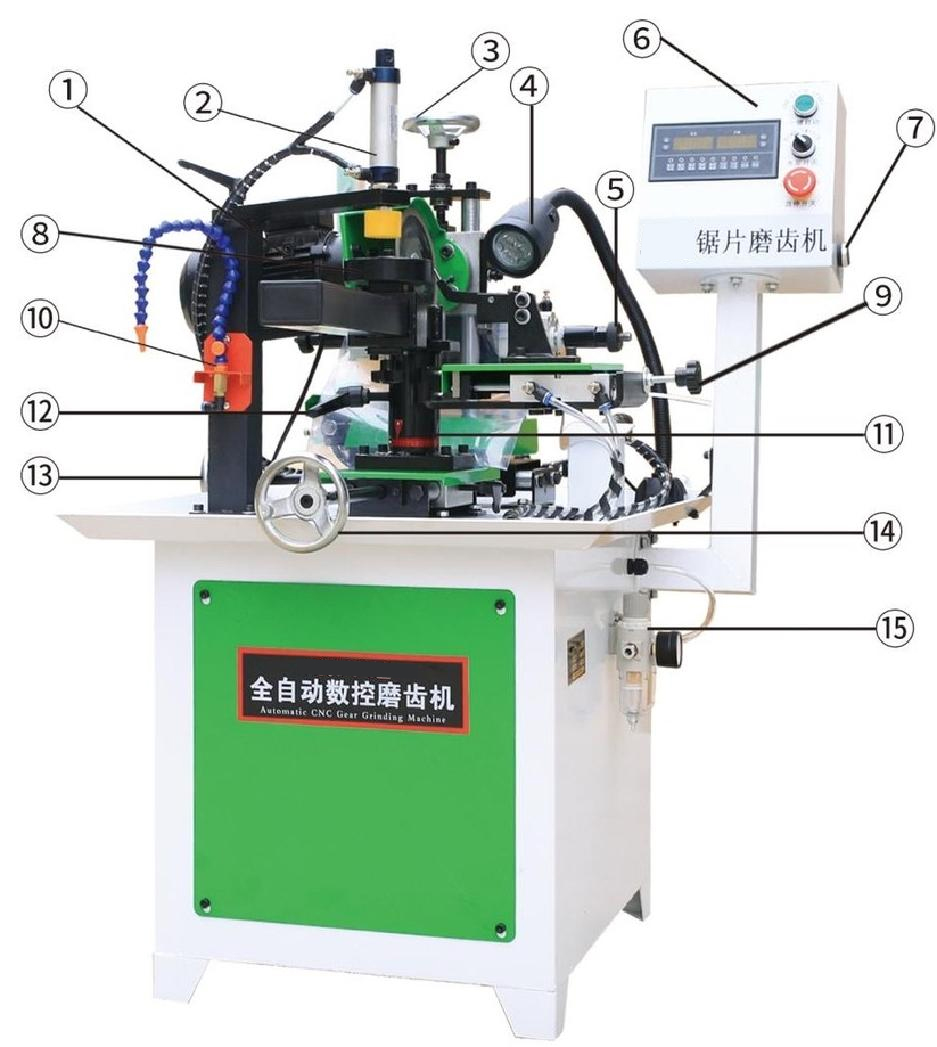

| Structure |

|

|

1.grinding wheel drive motor

2.Pressure cylinder

3.Motor lifts handwheel

4.Work light

5.Round nuts with left and right teeth

6.Computer control box

7.Grinding wheel switch

8.Walking deck

9.Pitch adjusting screw

10.Cutting fluid pipe

11.Vertical shaft

12.Vertical shaft locking handle

13.The motor moves the handwheel left and right

14.Table hand-wheel

15.oil-water separator |

| Parameter |

| |

Voltage |

220V |

|

| Blade size |

100-600mm |

| Pitch |

5-45mm |

| Working pressure |

0.6Mpa |

| Pulling speed |

0-55/min |

| Power |

550W |

| Speed of grinding wheel |

2850r/min |

| Grinding wheel specifications |

150*32*10mm |

| Tooth shape |

left and right teeth, flat teeth, three left and one right, three right and one left

|

| Maintenance |

1.Equipment must be regularly maintenance in daily use,Effectively maintain the normal operation,The maximum service life.

2.Regularly check grinding wheel grinding wear and change in time,Use wear serious ground will increase the friction coefficient ,Damage to the grinding wheel motor spindle bearing ,And affect the saw blade tooth grinding precision.

3.End of each shift work should be clear in time chip or dust on the surface of the table ,Make sure don't jam the cutting fluid backflow.

4.Linear guide slider come on 1-3 times in each shift,Ensure the slider inside ball at work to get sufficient lubrication.

5.Oil-water separator must be loaded with special oil cylinder or 10# engine oil ,Periodically check the oil loss and add in time;After long time use cups will fill in the waste water,emissions should be regularly. |

| Display |

|

|

|

Note |

|

The machine needs to be connected to an air compressor, which needs to be provided by the customer themselves. |

|

Item Number:153212 |

|

|

You can make

order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|