|

|

新建网页 1

新建网页 1

新建网页 1

新建网页 1

新建网页 1

新建网页 1

新建网页 1

新建网页 1

|

|

|

Salt water spray testing machine is for various

materials surface treatment, including coating, electroplating, organic

and inorganic skin film, anodic treatment, anti-rust oil and other

anti-corrosion treatment to test its corrosion resistance, so as to

establish the quality of products.

|

|

|

|

|

All materials:

Laboratory of

imported PVC board, thickness of 5 mm, durable temperature at 85 ℃.

The seal cover

of the laboratory is made of imported European acrylic plate with a

thickness of 5mm.

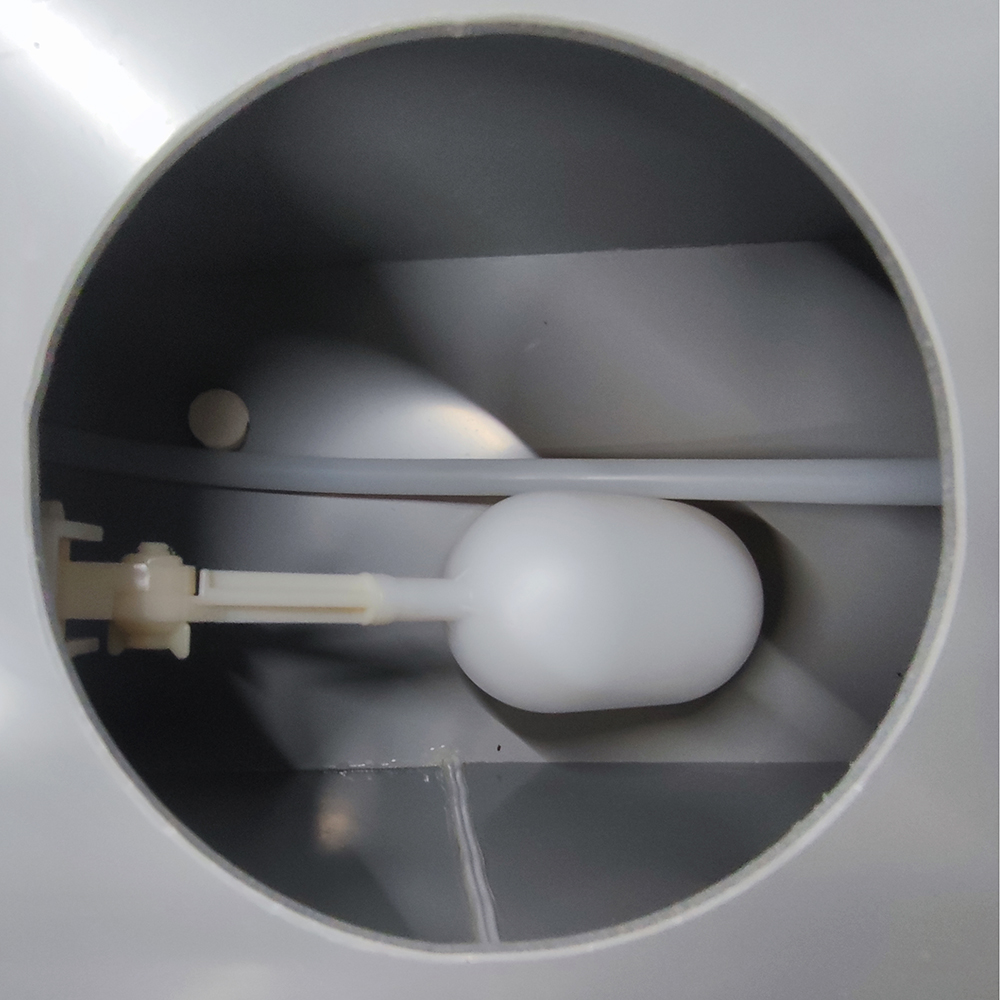

The refill

bottle adopts hidden type water level gauge, which is easy to clean and

is not prone to

break.

The pressure

air tank is 304 stainless steel and high pressure resistant tank

with excellent thermal insulation performance.

The basket of

the laboratory adopts a plane dividing frame, which can be adjusted at

any Angle. All sides

where the fog falling and the sides which are affected by fog are

exactly the same, and the number of test pieces is large.

|

|

Parameters:

Voltage: 110V

Power:2000W

Laboratory volume: 110L

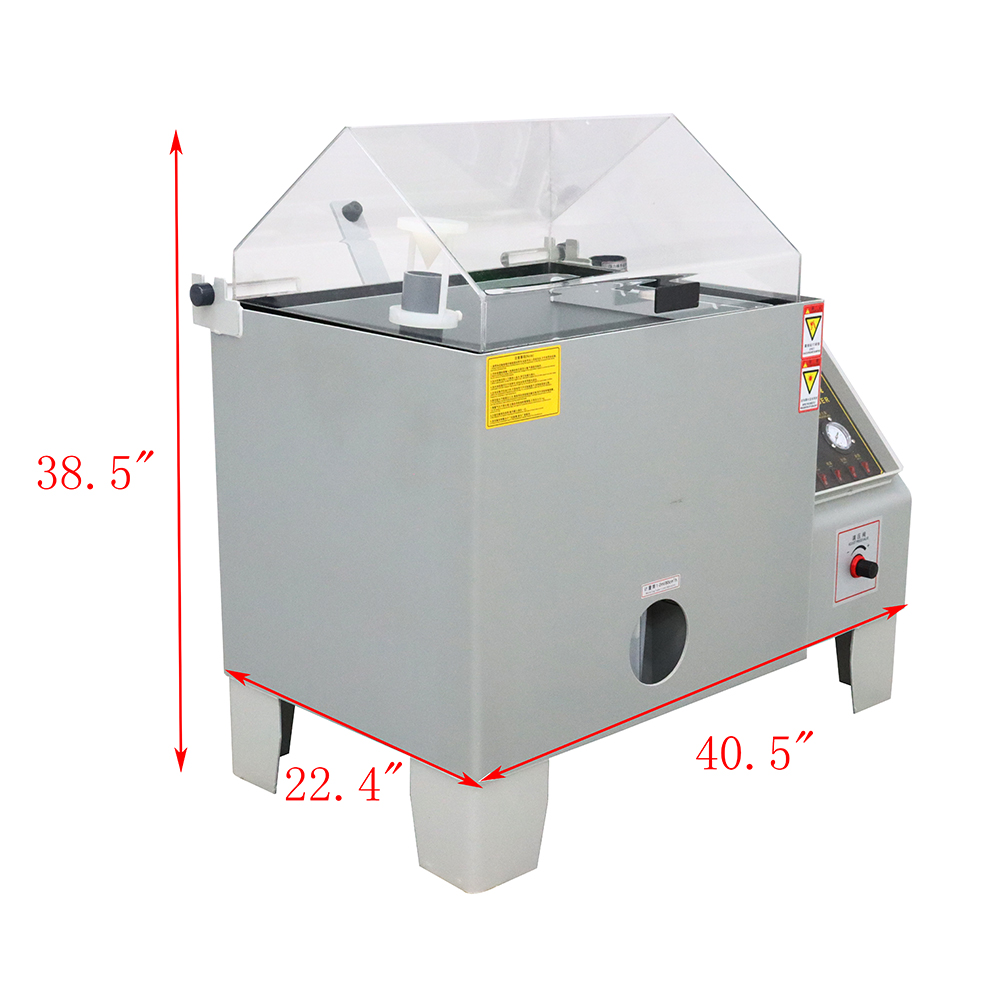

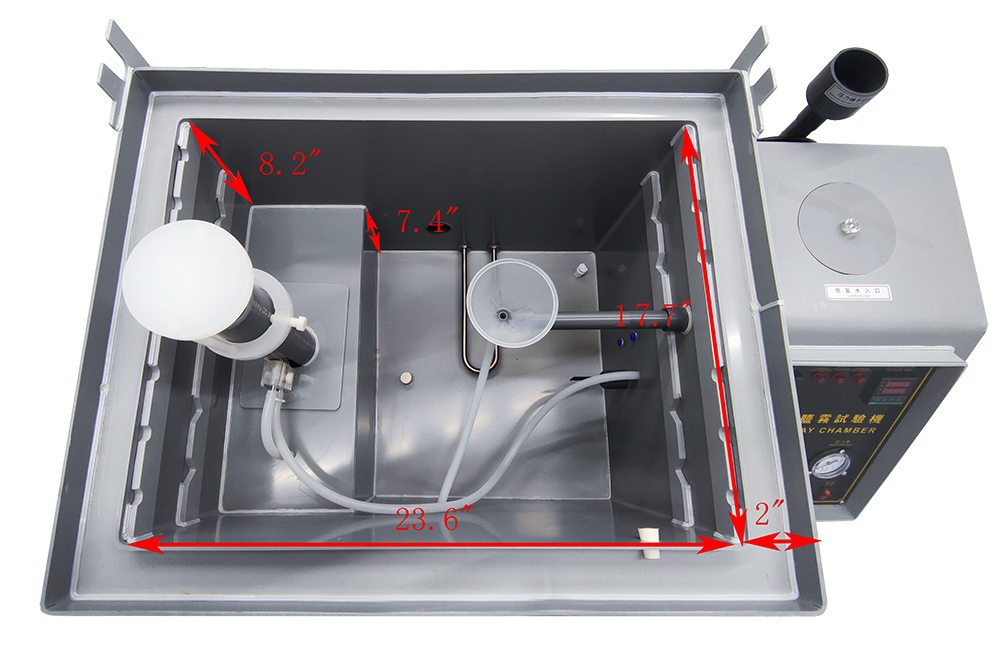

Inner size: 23.6*17.7*15.7 inch (600*450*400mm)

Outer size: 40.5*22.4*38.5 inch (1030*570*980mm)

Spray method: continuous

|

|

Features:

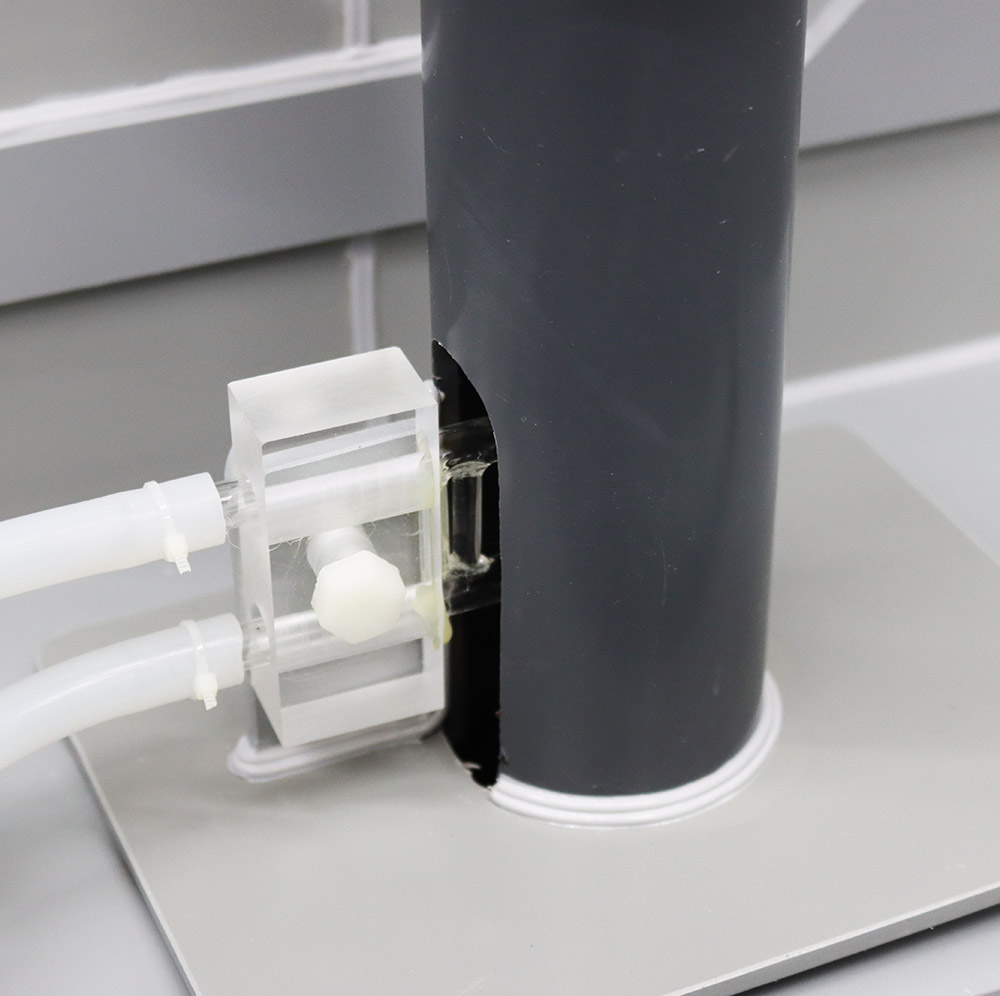

All equipment needed in the

test: Spray nozzle, salt water barrel, test piece support, spray liquid

collection container, test chamber, salt water, supply tank, pressure

tank, supply equipment and exhaust equipment required for compressed

air, the device

is shown in the figure, and the test is conducted as follow.

Blunt material is required,

it is required that the material itself cannot be corroded, and it can

not affect the corrosion test.

The fog nozzle cannot spray the test liquid directly to the sample ,

the solution at the top of the spraying chamber cannot drop on the test

piece.

The test liquid dropping from test piece cannot flow back to the salt

bucket again for the test.

The solution should not contain grease and dust, so you have to prepare

an air cleaner.

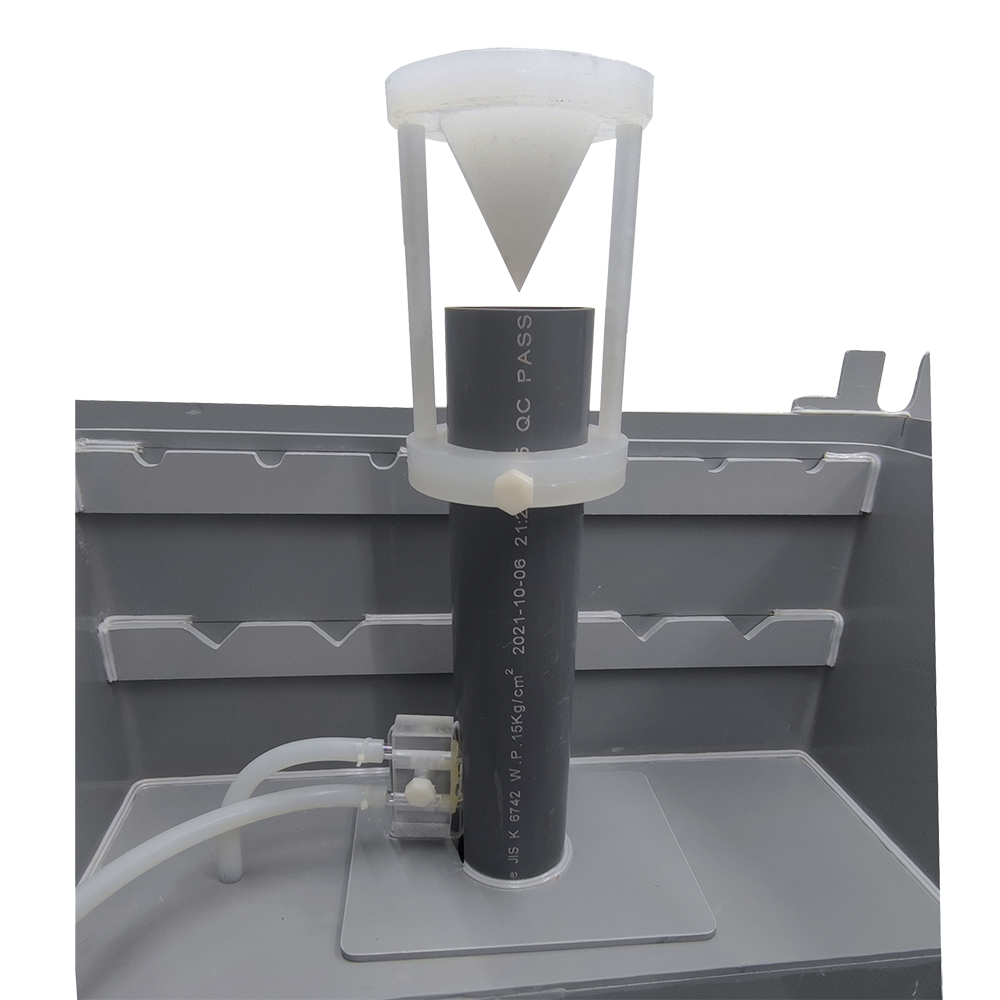

The level area of the spray taking device is 80 cm2, the diameter is

about 10 cm. Put the spray taking device beside the test piece.

Spray liquid should be collected

for at least 16 hours,

and the average of the solution collected in one hour is 1-2ml. Use the final average to represent

the amount of spray.

The concentration of the Sodium Chloride Solution should be maintained

at 40~60g/L.

The temperature of the pressure barrel should be kept in 47+1

DEG C,

temperature of the

salt water

barrel should be kept in 35+1

DEG C.

|

|

Note: The panels of the two

models are delivered randomly.

|

|

Details:

|

|

|

|

Item

Number(239015):

1*Salt spray testing chamber

|

You can make order with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from

Monday-Friday; Not on the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service

or technical support from us with low cost. |

|