|

|

|

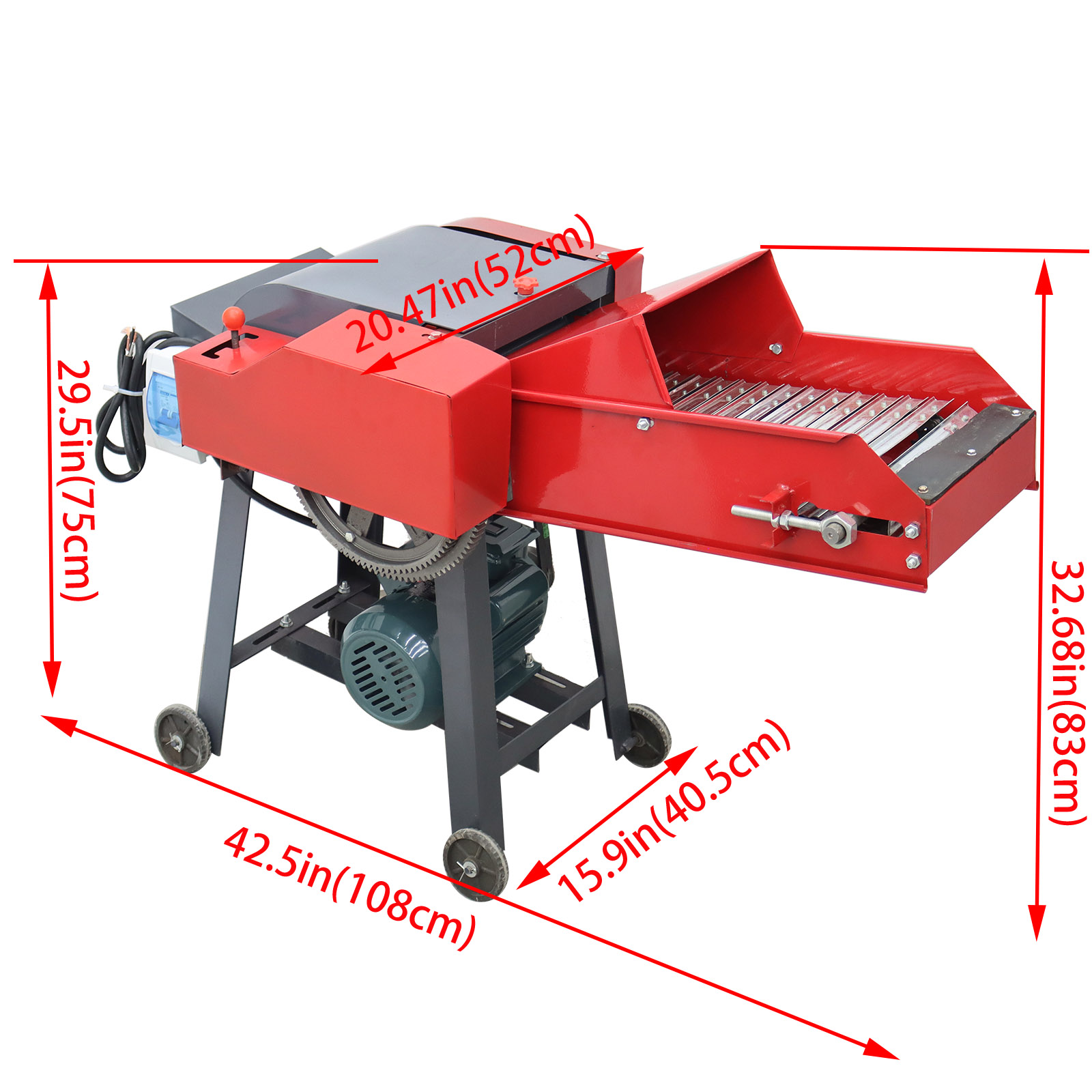

6-blade hay cutter

with conveyor belt |

|

This machine is suitable for cutting various crops such as grass, corn, wheat, peanuts, beans,

straw, etc. Processed feed is easier to store. It is an

essential machine for farmers, small and medium-sized feed processing

plants, and farms; At the same time, this machine can also be used in

conjunction with a feed granulator, making it convenient for the feed

machine to shape feed into pellets. |

|

|

|

Note:

1. In addition to

debugging according to the debugging method, the machine must be

carefully checked for any tools or objects that hinder startup and

operation, and all parts of the machine must be tightened before

starting up.

2. Before starting the machine, it is

necessary to check whether there are sundries in the machine. Except for

processing straw, nothing is allowed to be stacked on the feeding table.

3.

Run for 2-5 minutes before operation, check whether the rotating speed

meets the requirements of the machine, never allow overspeed, and check

whether other parts are abnormal. If everything is normal, the feeding

can be started, and the feeding cannot be excessive, so as to prevent

damage to the supporting power unit and machine parts due to overload

operation.

4. When the machine is

operating, it is forbidden to stand at the grass outlet to prevent

flying objects from hurting the body.

5. Operators are not

allowed to wear gloves, sleeves must be fastened, and those with long

hair must wear safety helmets. All personnel must leave the rotating

plane of belt and rotating parts.

|

|

Product parameter: |

|

|

|

| Product Material: |

Cast iron spray painting |

| Production efficiency: |

500-1000KG/H |

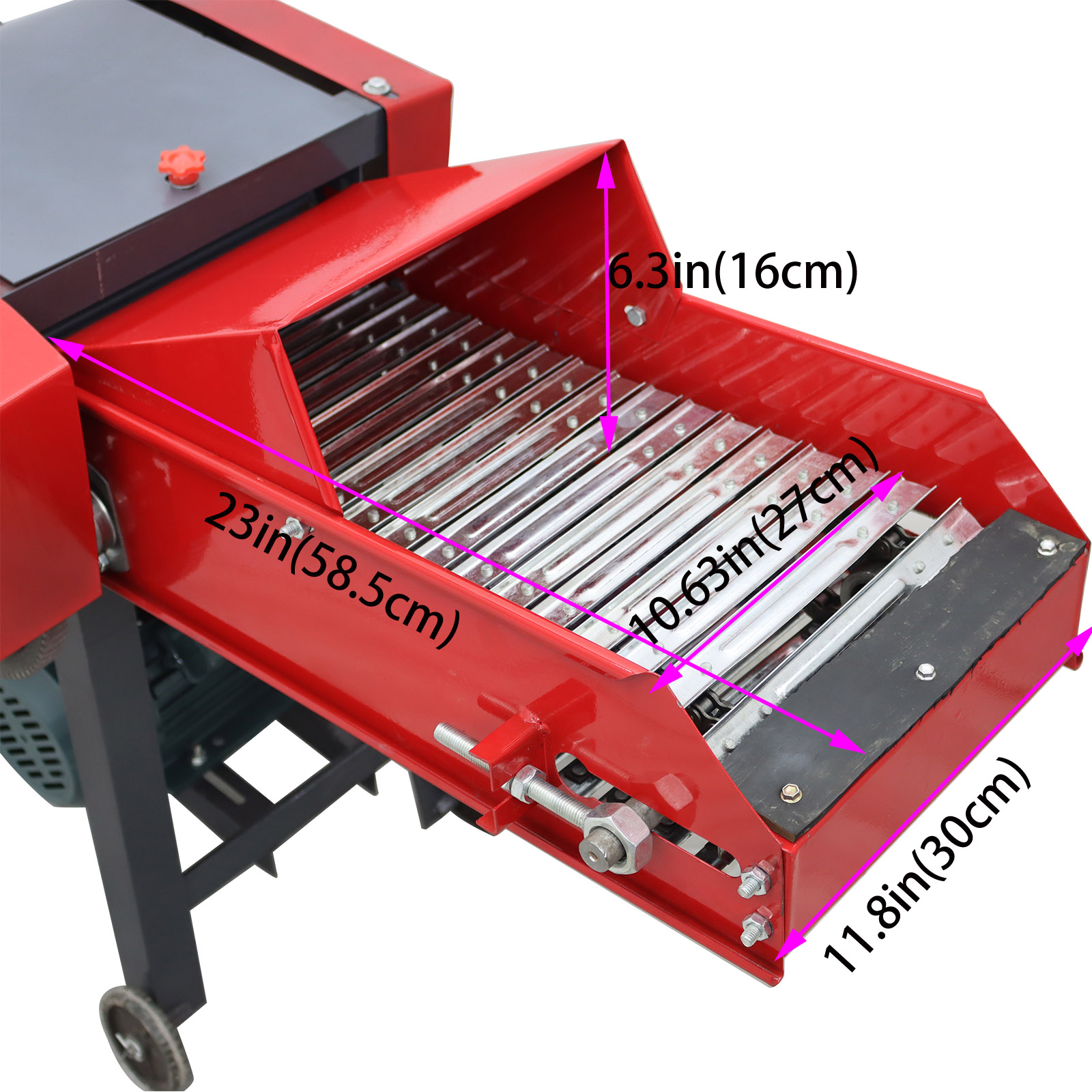

| Size of feed inlet (with

conveyor belt): |

23in*11.8in(58.5cm*30cm) |

| Power: |

3KW |

| voltage: |

220V |

| Applicable Industries:

|

Farms, Home Use, Retail |

|

|

Product analysis: |

|

|

Feature: |

|

This machine is equipped with a widened

and thickened feeding port, which is solid and firm. All kinds of grass

can be fed easily. It is equipped with a conveyor belt, which can feed

automatically, which is more convenient and fast. |

|

|

This machine is equipped with a thick

and sturdy bracket, which is more sturdy and durable. |

|

This machine is

equipped with a voltage display screen for a more intuitive reference to

whether the voltage is stable. |

|

|

This machine is

equipped with high-quality high-power motor. |

|

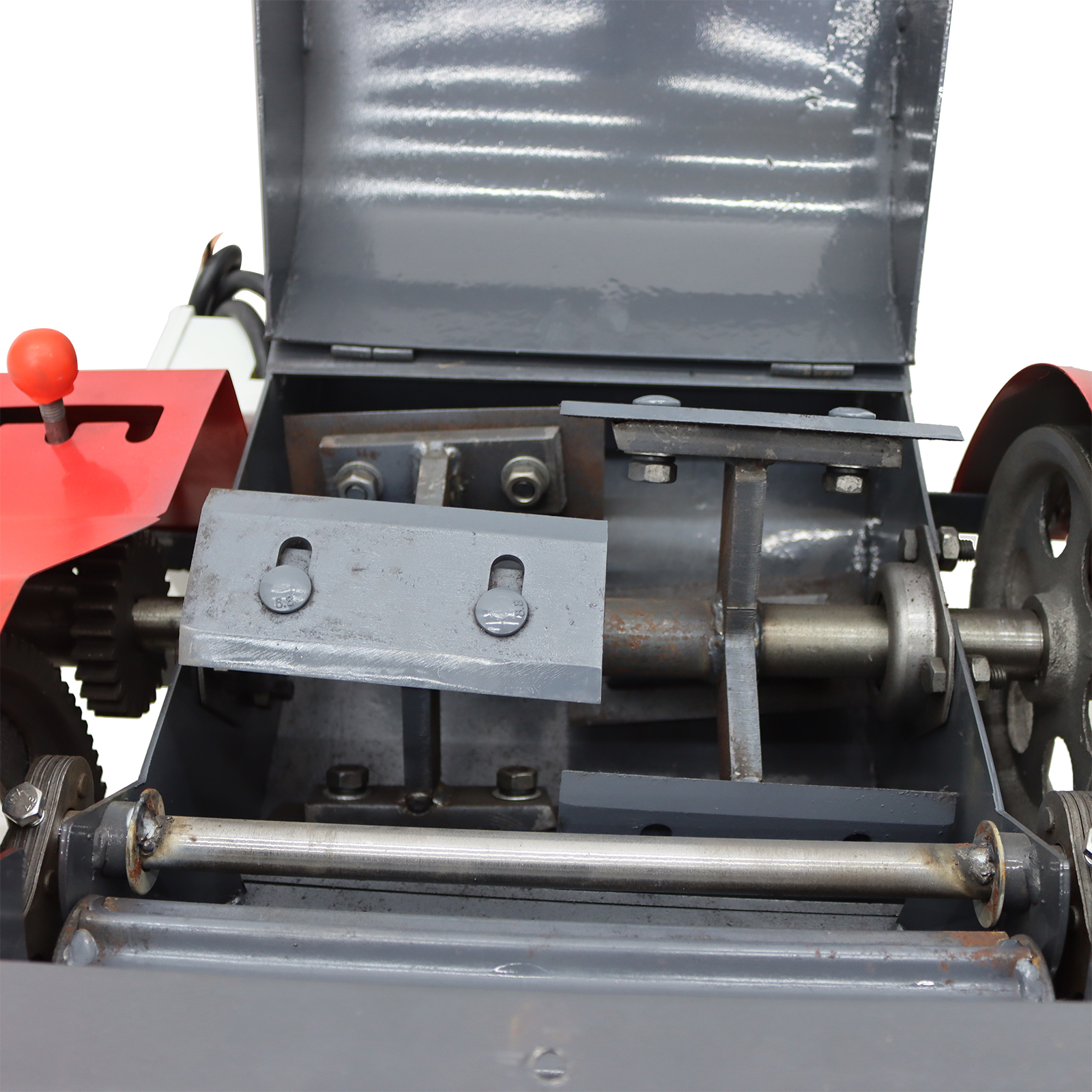

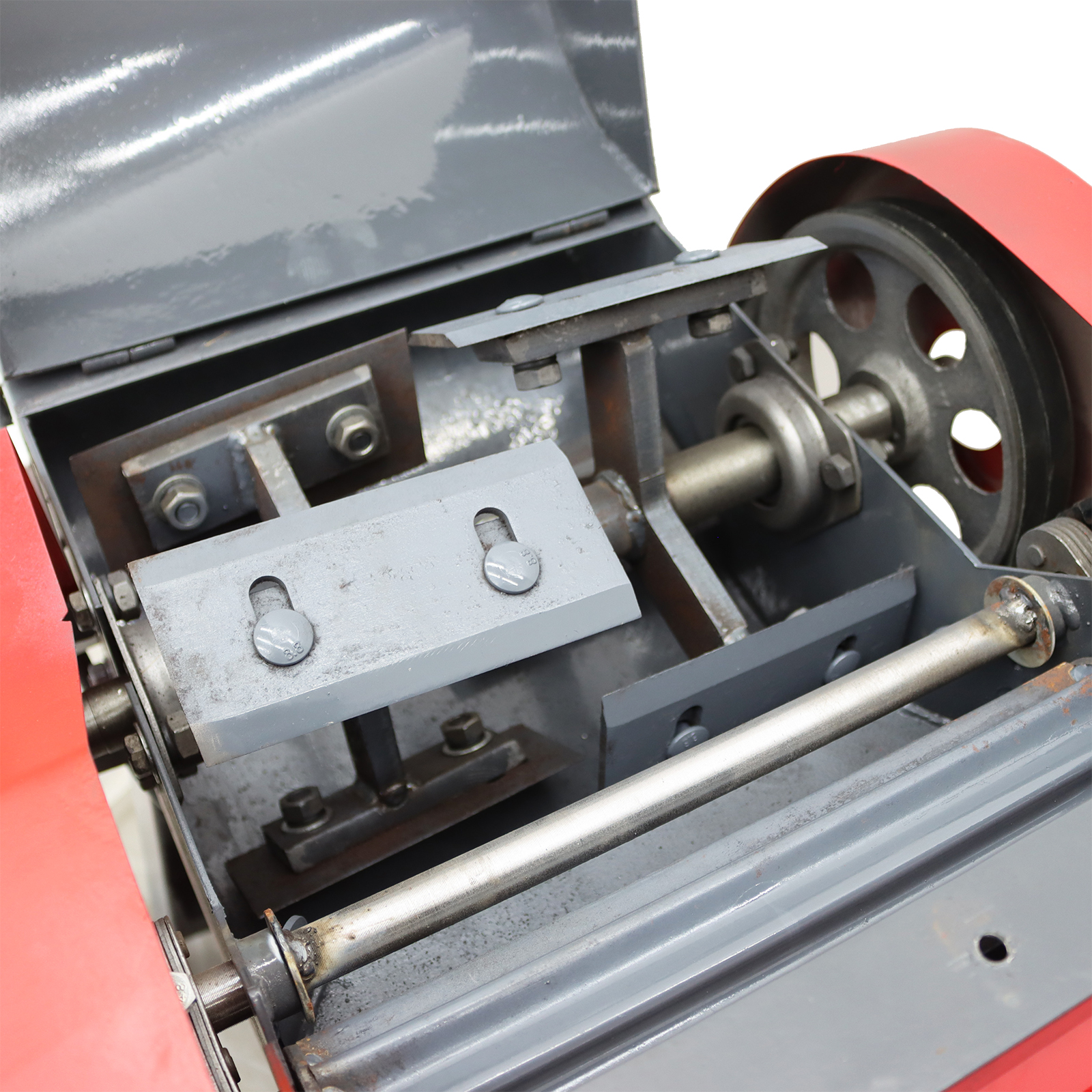

This machine is equipped with 6 sets of

thickened blades, which can easily cut materials. Double-sided blades

extend the service life of the blades. |

|

|

This

machine is equipped with 4 movable wheels, making it convenient for

customers to move and transport. |

|

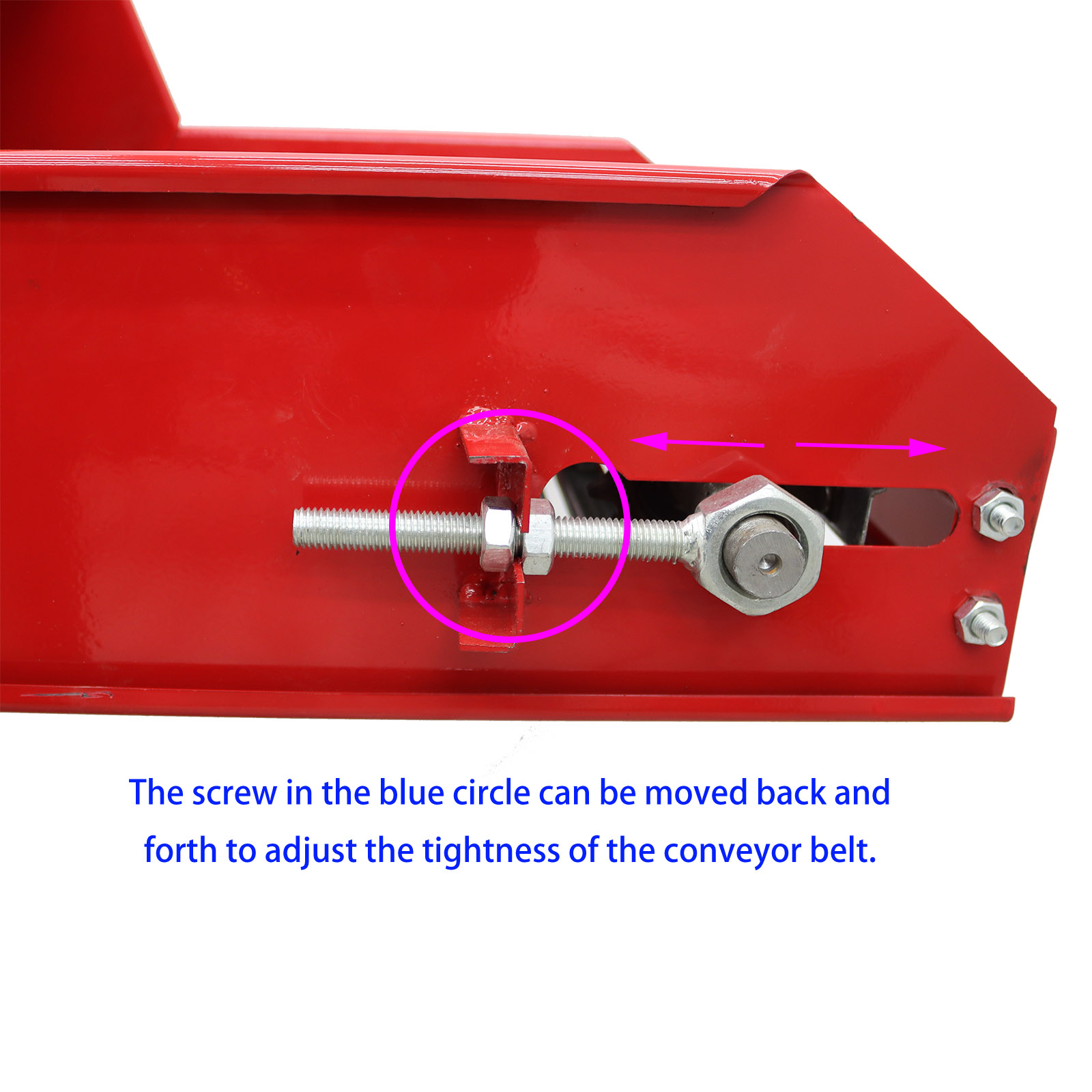

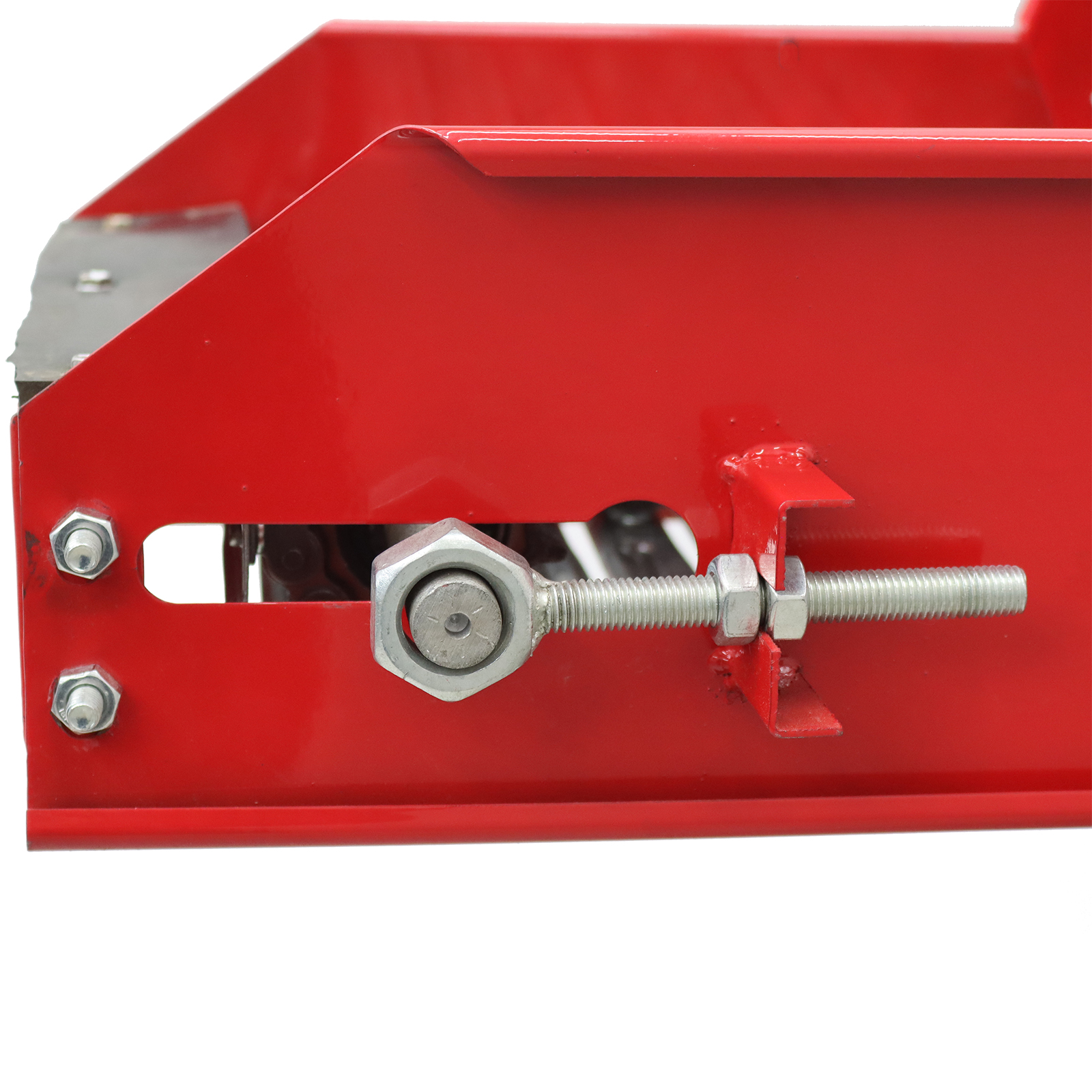

The screw in the black circle can be

moved back and forth to adjust the tightness of the conveyor belt. |

|

|

Customers can choose the length of

material cutting by themselves, and there are two gears for customers to

choose. The gears of the

new machine may be tightly engaged (in the initial use of gear shifting,

manual rotation of the gears is required after shutting down to assist

in switching) |

|

This machine is equipped with lock nuts

to ensure the locking and sealing of the engine room and improve the

safety. This nut must be

locked when the machine is working.

|

|

|

This machine is equipped with air

switch, which is safer and more secure. |

|

|

We suggest that

high-power machines should be directly connected to the main power

supply, as the voltage reaching the machine is stable. If the voltage is

unstable and the current exceeds the rated current of the motor, it is

easy to burn out the starting capacitor.

It is recommended to

directly connect to the power supply as much as possible. If the machine

is not connected to the power supply, different situations may occur,

and the wires are not durable. The wires will gradually burn out over

time.

|

|

Precautions for operation: |

|

In order to ensure the safety and normal operation

of the person and the machine, a special person shall be assigned to be

responsible for the storage and use of the machine. The machine shall

not be operated without learning this procedure and operation technology

and reading the familiar instructions.

1. In addition to commissioning according to the

commissioning method, before starting, the machine must be carefully

checked to see if there are tools and objects hindering the startup and

operation.

2. Before starting the machine, it is necessary to

check whether there are sundries in the machine. Except for processing

straw, nothing is allowed to be stacked on the feeding table.

3. Check whether the electrical equipment is normal

and safe.

4. Check whether the running direction of the main

shaft conforms to the direction indicated by the arrow on the casing. If

not, immediately adjust and close the power switch to ensure the correct

operation of the machine.

5. Run for 2-5 minutes before operation, check

whether the rotating speed meets the requirements of the machine, never

allow overspeed, and check whether other parts are abnormal. If

everything is normal, the feeding can be started, and the feeding cannot

be excessive, so as to prevent damage to the supporting power unit and

machine parts due to overload operation.

6. Feed crops evenly, not too much, so as not to

block the feed inlet. The operator's hand shall not be close to the

feeding belt during operation.

7. In case of blockage, stop the machine

immediately. After the machine stops stably, open the upper cover, clean

the blockage, and then restart.

8. Always pay attention to whether there is

abnormal sound during the operation of the machine. Shut down and power

off immediately in case of abnormality.

9. There shall be no mortar, sand, stone, iron

wire, tool parts or other sundries in the crops to be processed to avoid

damage to the machine or accidents.

10. At the end of each shift, the power supply must

be cut off after all the crops on the feeding table are fed and no more

materials are thrown out at the outlet.

12. When the machine is operating, it is forbidden

to stand at the grass outlet to prevent flying objects from hurting the

body.

13. Operators are not allowed to wear gloves,

sleeves must be fastened, and those with long hair must wear safety

helmets. All personnel must leave the rotating plane of belt and

rotating parts.

|

|

Details: |

|

|

|

|

|

|

|

|

product

advantages: |

|

1.

This machine is equipped with widened and thickened feeding ports, which

are sturdy and firm. All kinds of grass can be easily fed.

2. The feeding port can be installed separately and can be disassembled

and placed when not in use, saving space.

3. This machine is equipped with a high horsepower and high-quality

electric motor.

4. This machine can achieve the cutting and crushing of wheat straw,

hay, and other grains, as well as the crushing of corn, rice, millet and

other grains. It is versatile and more convenient.

|

|

Product display: |

|

|

|

|

|

|

|

Item Number:

1*6-blade hay cutter with conveyor belt (239925) |

|

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|