|

|

|

Full

Automatic Electric Fish Fillet Cutting Machine 110V |

|

|

|

|

|

|

|

|

Product

Overview |

|

The automatic fish fillet cutting machine is

a special fish processing device with high automation and high

efficiency, and is designed for cutting fish meat into fish

fillets quickly and neatly. By the use of the machine, the

production efficiency and product consistency are greatly

improved, the labor cost and operating strength are effectively

reduced, and cleaning and maintenance are easy and convenient.

The automatic fish fillet cutting machine can be used for

cutting various fish meat and other meat, such as snakehead

fishes, grass carps, salmons and tilapia, and is suitable for

meat processing plants, aquatic product processing plants, large

catering industries and other units. |

|

|

Product

Parameters |

|

Model |

Single chamber |

|

Voltage |

110V |

|

Power |

1.75KW |

|

Fillet thickness |

2.5mm |

|

Speed |

180-280 fillets per minute |

|

Product size |

72.5*88*83.5cm (28.54*34.65*32.87 inches) |

|

Net weight |

151kg (332.9LBS) |

|

|

|

Attention |

|

1. Be sure to take out the feeding plate before

starting the machine.

2. Remove the main thorn and big thorn and put

the fish meat into the machine.

3. After the fish meat is put in, take out the

hand board first and then turn it on. There should be no other

foreign objects in the fish tray.

4. Before commissioning, the machine must be

fixed (shake the machine vigorously by hand and turn it on again

after it is stable).

5. The grease must be added to the screw beside

the lifting motor regularly.

6. Please don't put your hands into the machine

to avoid accidental injury, and don't get close to flammable and

explosive products around to avoid dangerous accidents.

7. All parts in contact with food shall be

cleaned and disinfected regularly. |

|

|

Product

Features |

|

|

|

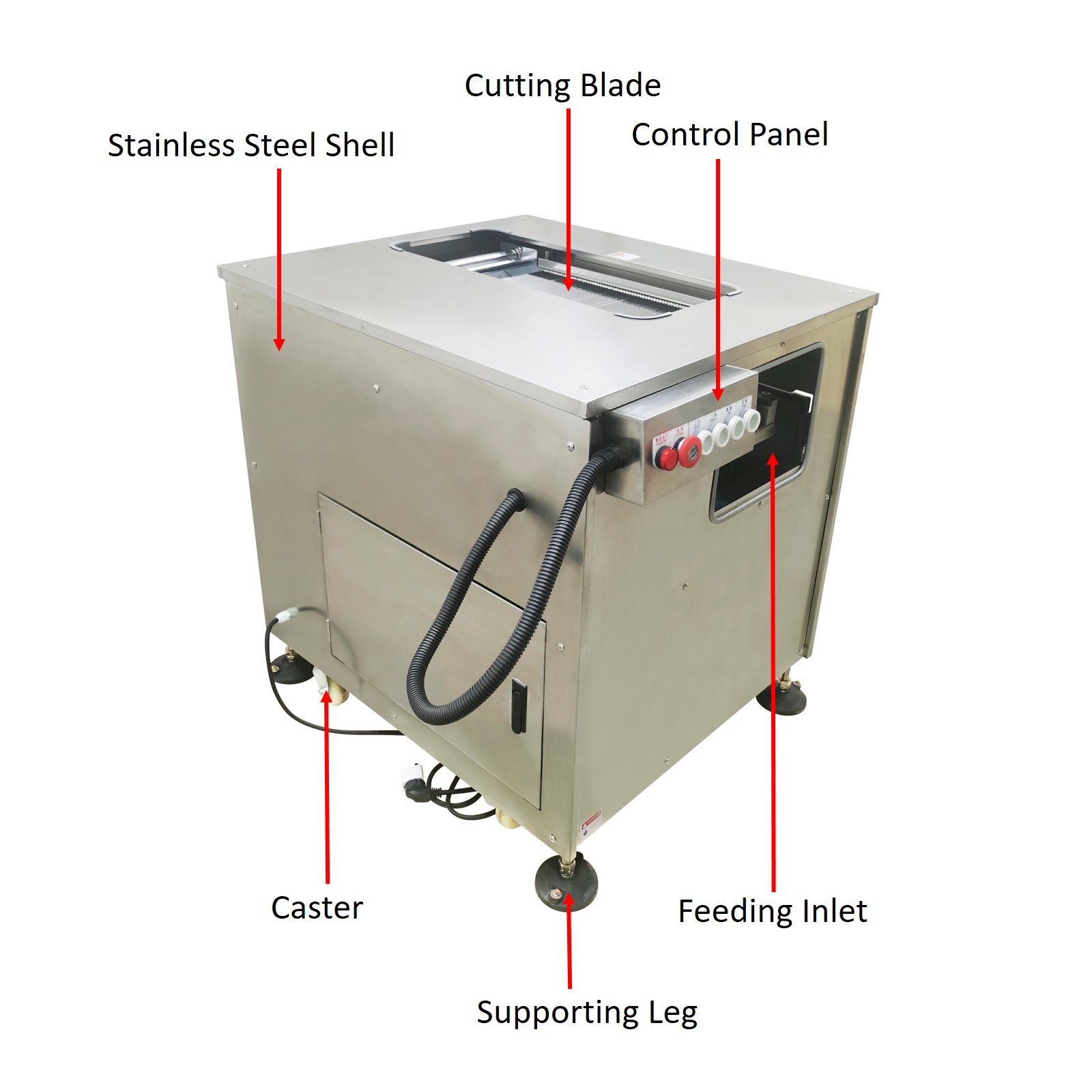

| The

machine shell is made of high-quality thickened stainless steel

materials, is firm and durable, easy to clean and resistant to

corrosion, and is not prone to precipitation of harmful

substances and rusting, and has high impact resistance and high

structural strength. |

|

The

high-performance motor is adopted to provide stable driving

force, has the power of 1.75KW, can reliably operate in

different working environments, has high applicability and

effective heat dissipation, and is low in noise and high in

working efficiency. |

|

|

|

| The

control panel is of an integrated structure, the functions of

indication, emergency stop, ascent, descend, jog and starting

can be fulfilled and controlled effectively and independently,

the control effect is greatly enhanced, and the button type

waterproof switches are easy to use and operate. |

|

The sharp alloy

blade is precisely manufactured and combined orderly, and the

fish meat can be quickly cut into the fish fillets with the

thickness of 2.5mm. The blade is sharp and durable, is

convenient to clean and maintain, and simulates manual cutting

of fish fillets. |

|

|

|

| The

cutting machine is equipped with a supporting assembly which

comprises universal wheels and supporting legs. The machine can

be conveniently moved to various places through the universal

wheels, and be stably supported through the supporting legs, and

the applicability is greatly enhanced. |

|

The automatic fish

fillet cutting machine is an efficient cutting device, greatly

improves the production efficiency and product quality, can be

widely used for slicing various fishes and meat quickly and

neatly, and is an ideal choice for aquatic product processing

plants, food plants, pre-made food processing centers and so on. |

|

|

Operation

Method |

|

1. Place the machine horizontally in the

workplace, tidy up the ground wire and adjust the bolts of the

machine base to make it stable and reliable.

2. Check whether the bolts in all parts of

the machine are loose, and take corresponding measures. Check

all parts for foreign bodies and clean them in time to avoid

damaging the tool.

3. Preliminary cutting steps before work

①

Put the fresh boneless fish flat on the "hand board", send it to

the "fish holding board", press the fish by hand, and take it

out of the "hand board" to make the fish flat on the "robot fish

bin"

②

Press the "Start" switch and start to slide horizontally from

left to right. After the machine cuts the fish, the fish holding

plate will automatically descend to support an emergency stop

with one beat, support single control over fish tank and cutter,

support inching cleaning of equipment, and only support start

and emergency stop after releasing fish. Start the fish cutting

action which will be automatically completed and stopped. After

cutting, use the "take-off board" sheet to take out the fillets. |

|

|

Product

Display |

|

|

|

|

|

Item Number (020489): 1 x

Electric Fish Fillet Cutting Machine 110V |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|