|

|

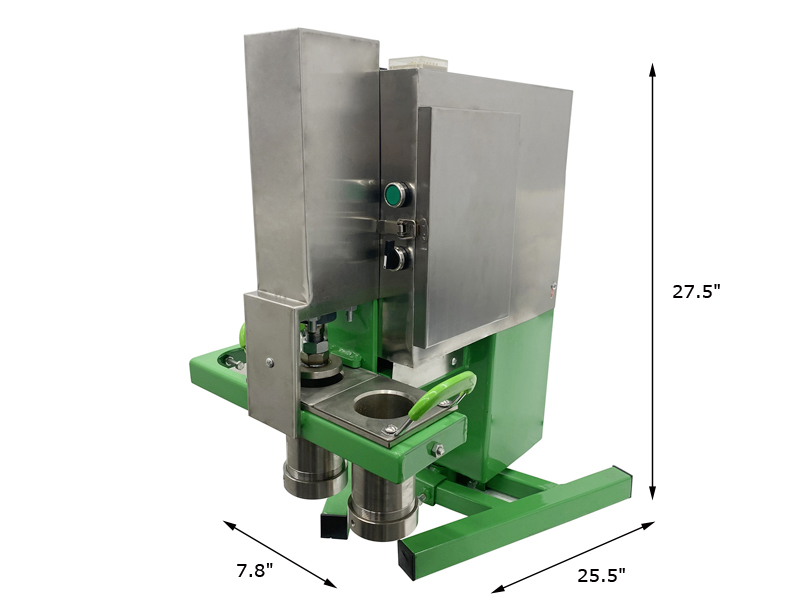

Product Overview

110V Commercial 36pcs

Automatic Electric Dough Divider and Rounder

|

| This dough dividing and rounding

machine uses the geometric dividing principle and the eccentric

swinging principle to divide the dough into 36 pieces of dough

of uniform shape and equal weight within 4-8 seconds, which

saves time and effort and greatly improves the production

efficiency. At the same time, this machine can also divide the

dough into a round shape. After the dough is divided and

rounded, the weight of the small dough is the same, and the

structure is dense, which can save labor and eliminate the

difference caused by labor. The cutter head is easy to clean. It

is a good helper for commercial kitchens! |

| Voltage: |

AC110V |

| Power: |

2HP(1.5kW) |

| Weight per dough: |

0.7oz-2.5oz(20g-70g) |

| Quantity of dough after

dividing: |

36PCS |

| Dough rounding takes

time: |

4S-8S |

| Package size: |

33.1"*30.7"*65.0"(84cm*78cm*165cm) |

| Net weight/Gross weight: |

906.0LB(411kg)/1009.7LB(458kg) |

Note: If you need to

process dough with other weight specifications, you can contact

us to customize.

The

dough can not reach 100% perfect round ball after the rolling

processing!! |

| Product Features & Advantages |

|

|

|

|

Control Panel

The control panel integrates the rounding time setting,

transformation switch, start and stop switch for more convenient

operation. |

Power Switch

Power switch one key start, with two indicator lights, the green

light means the machine is running, the red light means the

machine is stopped, easy to understand. |

Heat Emission Hole

The machine is designed with heat emission holes, which can

discharge the excess heat generated by the motor during work and

protect the equipment. |

|

|

|

|

Hydraulic

Device

The hydraulic system provides a steady pressure to ensure that

the dough is subjected to even force during the division and

rounding process, thus guaranteeing the quality and shape of the

dough. |

Press Lever

After the dough division is completed, the automatic dough

rolling effect can be quickly realized by controlling the press

lever, which is simple to operate and saves time and effort.

(Please note: the

dough can not reach 100% perfect round ball after the rolling

processing!!) |

Rapid Prototyping

It can quickly divide and round the dough, and the forming

effect is good, the size and weight of each dough are uniform,

and the operation is simple and convenient. |

|

|

|

|

Adjustable Dough Weight

The weight of the dough can be adjusted according to the actual

production needs by turning the knob, it is simple and

convenient. The weight adjustment range of each dough is 20-70

grams. |

Dough Divide

The parts of the dough dividing device in contact with the dough

are all food-grade materials which are evenly divided, safer and

healthier. |

Extra Accessories

Supplied with three replaceable

food-grade rounding pans, not easy to stick; Four

rubber floor mats at the bottom corners of the machine to

prevent movement. |

|

- The dough is divided and rounded at one

time, with high efficiency.

- The machine shell is painted, the surface is smooth and easy

to clean, beautiful and generous.

- The dough forming time is about 4-8 seconds, the time is

short and the efficiency is high.

- Unplug the left connecting pin and flip it to the right to

open the machine head, which is convenient for cleaning the

cutter.

- Pure copper core motor, durable; small footprint, space

saving.

- This machine

is ideal for producing pastries, pizzas,

cookies, burgers, bread, and more.

- It is suitable for use in restaurants,

schools, factories, bakeries, and other high-volume food

production environments. |

|

1. Turn on the switch. When the running

indicator lights up, the machine is running.

2. Run the machine without load to check

for any abnormal noise or jamming.

3. Please cleaning the dust of the machine

and the rounding pan before the new machine is used or is not

used for a long time. Please repeat the test run with

approximately 2 kilograms of dough until the machine head and

rounding pan are thoroughly cleaned.

4. After cleaning the machine head and

rounding pan, place the mixed dough (prepared according to the

product recipe) on a plastic tray, flatten it, and allow it to

rest for a period of time before production.

5. Put the dough-filled plastic tray into

the machine, aligning the tray's round hole with the cylindrical

pin on the rounding tray. Make sure they are properly positioned

and level.

6. Please Adjust the rounding height using

the lever at the back of the machine head. Avoid extreme scale

settings: too small damages the dough surface, while too large

reduces rounding effectiveness.

7. The rounding time should generally be

adjusted to around four seconds, and can be increased or

decreased based on the needs of the dough.

8. Adjust the pressure control knob to the

appropriate position based on the firmness of the dough. For

softer dough, reduce the pressure setting; for firmer dough,

increase the pressure setting. The dough should not be pressed

beyond the divider frame.

9. Once all preparations are complete,

press both start buttons simultaneously to begin the dividing

and rounding process for the dough.

10. While the machine is running, do not

place your hands inside the machine head to avoid finger

injuries.

11. If any abnormalities occur during

machine operation, promptly press the stop button.

12. After completing the operation, please

turn off the red power switch and the air switch. Wipe the

machine clean. Do not use a spray hose to flush when cleaning!!

|

| Product Presentation & Details |

|

Automatic Dough Divider and Rounder *1 |

Rounding Pan *3 |

Rubber

Mat *4 |

|

You can

make order with no worry.

Any concern just feel free to let us know, we'll reply in 24

hours in normal condition.

Handling Time: Shipping is usually made in 1-3 business days

after payments cleared. Orders are processed from Monday-Friday;

Not on the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the

consumables.

We stand behind our products all the item, so even if your

warranty period has expired, you can still seek for service or

technical support from us with low cost. |

|