|

|

110V

5-25kgs Liquid Filling Machine Semi-automatic Water Paint Bucket

Weighing Capping Filler

|

|

Semi-automatic liquid weighing, filling and capping machine is

characterized by large capacity, small volume, simple and

flexible operation, energy saving, high efficiency and

adaptability, integrating weighing, filling and capping in one

machine, with a weighing standard of 5-25kg.It is suitable for

all kinds of paints, inks, automobile paints, furniture paints,

adhesives (glue), resins, chemical solvents, curing agents,

lubricating oils, shoe glues, spray glues and other flowing

liquids. |

| Voltage: |

AC110V |

| Power(weighing

part): |

9W |

|

Filling Range: |

11lbs-55.1lbs(5kg-25kg) |

|

Working

environment: |

Temperature:

0-50℃, relative humidity: ≤90%RH (No condensation) |

| Package size: |

71.7"*29.5"*60.6" (182cm*75cm*154cm) |

| Net weight/Gross weight: |

385.8lbs(175kg)/451.9lbs(205kg) |

|

Caution:

Please use with your own air compressor. |

| Product Features & Advantages |

|

a.

Pressure Gauge

The high-quality pressure

gauge allows for convenient monitoring of the machine's

pressure while in operation process.

|

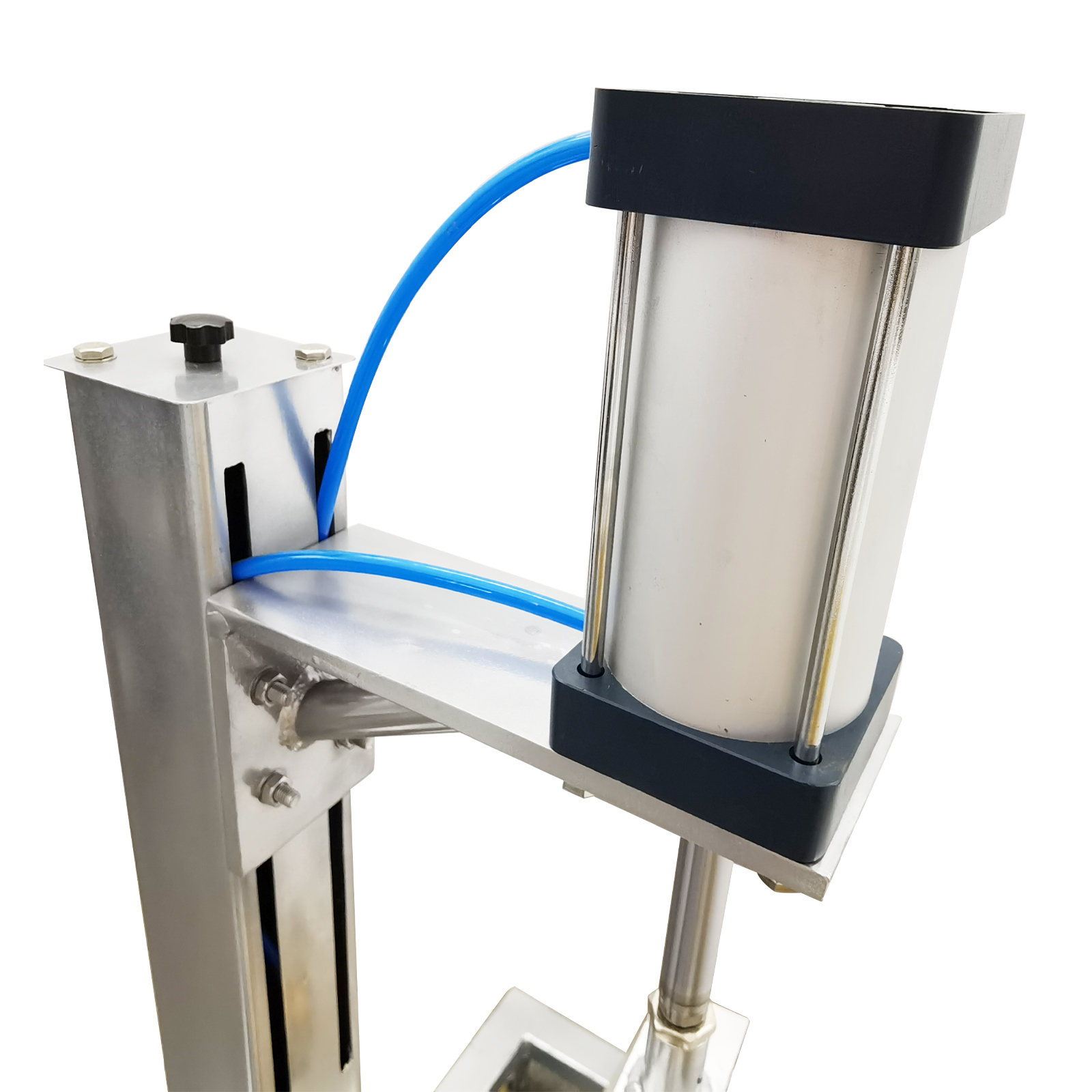

b.

Capping Device

The capping device ensures

that liquid container can be tightly closed after

filling, preventing liquid leakage and contamination.

|

|

|

c.

Foot Switch

The machine is equipped with a movable foot switch to

control the start and stop of the machine, freeing the

hands, which can greatly improve the work efficiency and

save worry and effort.

|

d.

Solenoid Valve

The solenoid valve can precisely control the flow rate and

flow speed of the liquid, ensuring the accuracy and

efficiency of the filling.

|

|

|

e.

Weighing Roller

The weighing roller not only has the characteristics of

simple structure, strong bearing capacity and long service

life, but also can feel the weight of the liquid in real

time, which improves the operating efficiency of the

equipment.

|

f.

Control Panel

The control panel is rich in functions, integrating

emergency stop switch, capping switch, filling start button

and capping start button, which is simple and convenient to

operate at a glance.

|

|

|

g.

Air Cylinder

The cylinder can control the working speed of the machine,

provide stable and reliable power support, and ensure the

efficient and stable operation of the production line.

|

h.

Anti-Drip Nozzle

The outlet nozzle can be easily removed and replaced.

Raising and filling device with an anti-drip nozzle, not

easily plugged, the filling process is efficient and

accurate.

|

|

|

i.

Pneumatic Diaphragm Pump

Aluminum pneumatic diaphragm pump provides efficient and

safe conveying performance. Made of aluminum alloy, it has

excellent corrosion resistance; it does not leak, does not

pollute the environment, is safe and reliable, and also

ensures the safety of operators.

|

j.

Caster

Equipped with two universal move casters, with the foot

gently stepping on the casters can be fixed, flexible

movement, fixed at any time.

|

|

|

k.

Fixed Bucket

This position is to hold the bucket in place, allowing the

bucket to be more accurately secured for the next capping

operation.

|

l.

Distribution Box

It has the advantage of small size, comprehensive features,

safer, easy to install, easy to use and maintenance.

|

|

| Product Presentation & Details |

|

Filling Machine *1 |

Gland Plate *1 |

|

You can

make order with no worry.

Any concern just feel free to let us know, we'll reply in 24

hours in normal condition.

Handling Time: Shipping is usually made in 1-3 business days

after payments cleared. Orders are processed from Monday-Friday;

Not on the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the

consumables.

We stand behind our products all the item, so even if your

warranty period has expired, you can still seek for service or

technical support from us with low cost. |

|