|

|

Product Overview

|

AC220V

2 in 1 Plastic Film Sleeve Sealing Cutting and Shrinking

Packaging Machine, Heating Tunnel for

Bottle Cans

|

| Our machine uses the PE, POF, PP, PVC

etc as packing material. After the process of sealing&cutting,

the products enter the shrink tunnel automatically. The machine

is suitable for shrink packing both single object and combined

objects. The object packaged by this machine, have follow

advantage: good looking, neatness, dustproof, dampproof, prevent

from broken, easy for carry and store. Shrink packing for many

industries, such as printing, pharmacy, floor, chinaware,

beverage, beer etc. |

| Product Parameters (Sealing

Cutting Machine) |

| Voltage

frequency: |

AC220V |

| Power: |

1.6kW |

|

Phase number: |

1 |

| Max. packing

dimension(L*W*H): |

15.7"*15.7"*15"(40cm*40cm*38cm) |

| Min. packing

dimension(L*W*H): |

9.8"*2.4"*5.5"(25cm*6cm*14cm) |

|

Max. sealing

length: |

25.6"(65cm) |

| Packing

speed: |

0-8pcs/minute |

| Load of

pushing board: |

44lbs(20kg) |

| Table

height: |

31.5"+2"(80cm+5cm)(adjustable) |

| Film

thickness: |

0.001"*0.0098"(0.03-0.25mm) |

| Film

material: |

PE, POF, PP,

PVC |

|

Working air

pressure: |

5~7kgf/cm2 |

| Net

weight/Gross weight: |

762.8lbs(346kg) /

1148.6lbs(521kg) |

|

Caution:

1. The height of the

object can not be less than 140mm, otherwise, the

vertical pushing board will hit the pushing air-cylinder, then

the air-cylinder will be broken very easily.

2. In addition to the power supply, this product also needs to

be connected to the air pump or air compressor. |

| Product Parameters (Shrink

Packaging Machine) |

| Voltage

frequency: |

AC220V |

| Power |

20kW |

|

Phase number: |

3 |

| Loading |

77.2lbs(35kg) |

| Tunnel size: |

70.9"*23.6"*15.7"(180cm*60cm*40cm) |

| Conveying

Speed: |

0-10.9yd/min(0-10m/min) |

| Temperature And Heating

Time For Reference |

| Shrinking membranes |

Thinkness(mm) |

Heating time(s) |

Temperature (℃) |

| PVC |

0.02-0.06 |

5-10 |

110-130 |

| PP |

0.02-0.04 |

6-12 |

130-170 |

| PE |

0.06-0.20 |

10-60 |

150-180 |

| POF |

0.03-0.10 |

8-16 |

130-170 |

| Product Features & Advantages |

|

|

The operation panel is simple and

clear, easy to operate, intelligent temperature control,

more accurate temperature. Multi-choice operation, manual

automatic replacement, separate control of film feeding and

heating, reduce machine failure. The emergency switch making

the operation safer and more reliable.

|

The

thickened upper film fixing device is made of high-strength

material, which can withstand greater tension and pressure

to ensure the stability and reliability of the fixing.

It

is suitable for heat shrinkable film such as

PVC, POF, PE, PP etc.

|

|

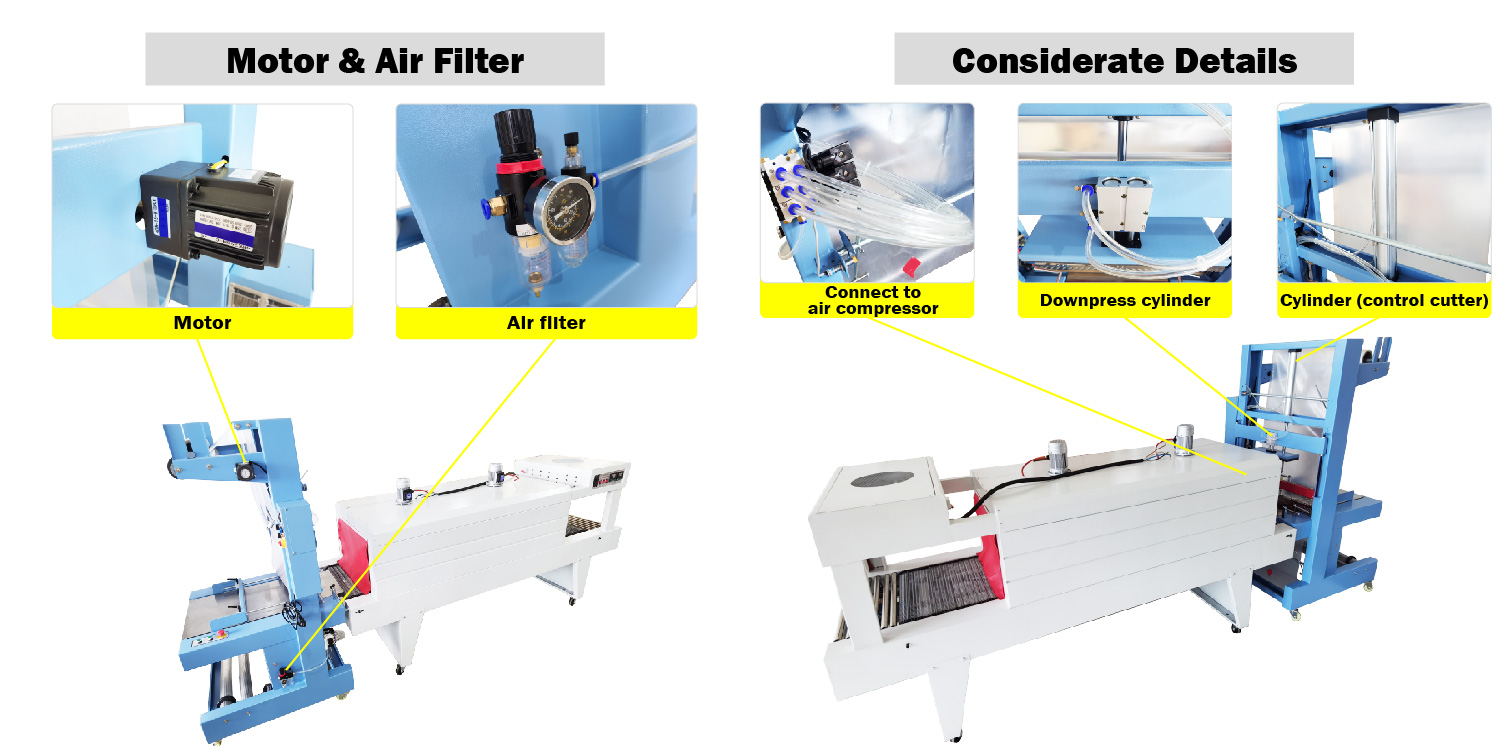

Film

feeding motor: copper wire motor, strong power, high

efficiency; Simple structure, can work stably for a long

time, high reliability, low maintenance cost.

Air filter: large flow, adjustable air pressure, can remove

the water in the gas, protect the cylinder.

|

Downpress

cylinder: after the object reaches the specified position,

press the object to keep the object smooth and orderly.

Cylinder for cutter: the cylinder pushes the sealing cutter

to seal, while lifting the sealing cutter, to achieve fast

and stable cutting action, greatly improve the cutting

efficiency and accuracy.

|

|

The

sealing cutter part is coated with Teflon coating, which is

resistant to viscosity and high temperature, no cracking, no

smoke and no pollution. The sealing frame is made of

high-quality alloy steel, and the frame is not easy to

deform.

|

The body

shell adopts spray painting process, smooth surface,

anti-corrosion and rust, easy to clean; The sleeve sealing

cutting machine is not only equipped with four universal

casters to move, but also has supporting legs, which can be

installed at the bottom when necessary to play a fixed role

in supporting the machine.

|

| Product Features & Advantages |

|

The control panel is rich in

functions, integrating switch, conveyor belt speed control,

hot air, fan cooling, heating tube heating, temperature

display meter, etc., which is simple and convenient to

operate at a glance; The hot air and fan cooling can

maximize the shrinking and shaping effect, and improve the

production efficiency.

|

The centrifugal fan has stable

operation, low noise, high efficiency and energy saving, and

can work continuously for a long time.

Adopts pure copper core motor, strong power, high

efficiency; Simple structure, can work stably for a long

time, high reliability, low maintenance cost.

|

|

The quartz

tube heating and the strong wind circulation of the big fan

make the temperature of the shrink furnace stable. When the

temperature of shrinkage furnace reaches the set

temperature, the machine will automatically stop heating;

When the temperature is lower than

the set temperature, the machine will automatically turn on

the heating device, which has the effect of energy saving

and environmental protection.

|

Adopting

high quality chain mesh conveyor belt with even distribution

of holes, flat surface, smooth running, strong loading

capacity and tensile capacity, high temperature resistance,

no deflection, which ensures good shrinkage processing

effect.

|

|

- It adopts

quartz tube Far-infrared heating method,while working, it can

shed far-infrared continuous, the large power cooling system

makes the tunnel temperature symmetrical, and it can reduce

electricity consumption.

- The transportation part adopts large AC motor, it can adjust

the speed stepless and there is a large load ability. It can

continuously work for a long time with running stable and

reliable.

- The transportation part of the middle and large machine adopt

the roller that can turn by itself while working, this make the

shrink effect of the bottom of the object better.

- Adopting special machine structure design, it looks more

beautiful and luxury, and the maintain becomes easy and

convenient.

- It adopts special method to control the temperature, which

combine the temperature meter and the solid-boost, it makes the

mistake bottom out. |

| Product Presentation & Details |

| Sealing Cutting & Shrinking

Packaging Machine *1 |

Accessory Kit *1 |

|

You can

make order with no worry.

Any concern just feel free to let us know, we'll reply in 24

hours in normal condition.

Handling Time: Shipping is usually made in 1-3 business days

after payments cleared. Orders are processed from Monday-Friday;

Not on the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the

consumables.

We stand behind our products all the item, so even if your

warranty period has expired, you can still seek for service or

technical support from us with low cost. |

|