|

|

|

|

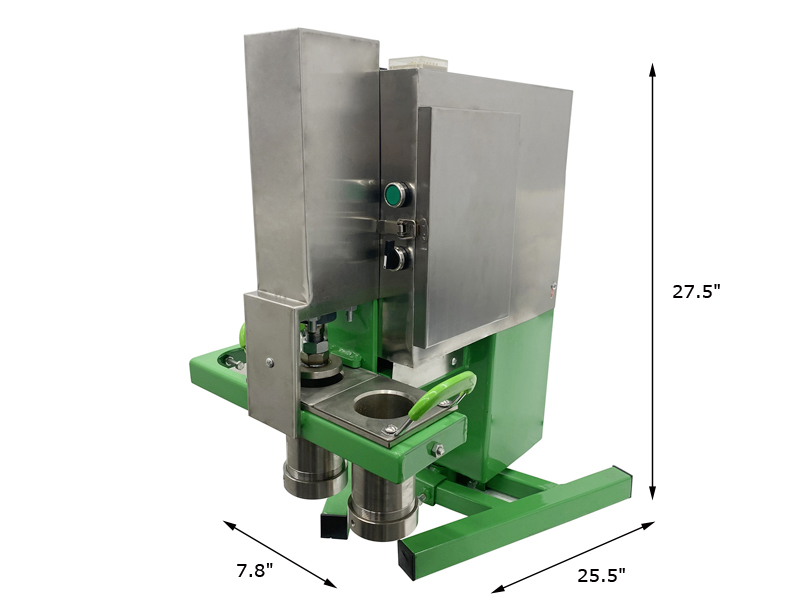

110V Mini Commercial

Dough Sheeter Desktop Electric Foldable Dough Pressing Machine |

|

|

|

|

|

|

|

|

Product

Overview |

| The desktop dough sheeter is a

common compact and multifunctional food processing machine, and

is mainly used for shaping various types of bread, pastries and

cookies, and making various types of puff pastry. By rolling and

stretching the dough or crust, the shortening wrapped in the

dough or crust is evenly dispersed. After multiple rounds of

rolling and folding, multiple-layer pastry can be made. The

dough sheeter has the advantages of simple operation, folding

design, speed and thickness adjustability, small occupied space

and long service life. The dough sheeter is suitable for

bakeries, cafes, central kitchens, hotels, cooling schools and

so on. |

|

|

Product

Parameters |

|

Model |

H-400F |

|

Voltage |

AC110V |

|

Power |

0.12kw |

|

Material |

304 stainless steel |

|

Driving mode |

Chain drive |

|

Material of conveyor belt |

PVC |

|

Speed of press roller |

0-10RPM |

|

Diameter of press roller |

89mm (3.5in) |

|

Range of press roller |

1-35mm (0.04-1.38 inches) |

|

Width of workbench |

400mm (15.7in) |

|

Machine size |

170x79x56cm (67x31.1x22 inches) |

|

Folding size of machine |

80x49x87cm (31.5x19.3x34.3 inches) |

|

Net weight |

98kg (216LBs) |

|

|

|

|

Attention |

|

(I)Personnel management

The desktop dough sheeter should be managed

and used by a specially-assigned person. When personnel changes

occur, handover procedures should be completed to ensure that

the subsequent operator is familiar with the use method and

precautions of the machine.

(II)

Operation

standards

1. It is strictly prohibited to wear any

gloves when operating the machine, so as to prevent gloves from

getting caught up in the machine and causing danger.

2. The buttons of work clothes should be

complete and securely fastened. Female workers must tie up their

long hair and put it in a headscarf to prevent their hair or

clothes from being caught up in the machine.

3. When the machine runs, it is strictly

prohibited to touch the material being processed near the press

roller and rotating parts with hands to avoid serious injury.

4. The gap between the press rollers should

be adjusted slowly and not quickly to avoid damaging the machine

or affecting the pastry effect.

(III)

Abnormality

handling

During the operation, if any abnormal

conditions are found in the machine (such as abnormal noise,

vibration and odor), the machine should be stopped immediately,

and professional personnel should be contacted for maintenance

in a timely manner. It is not allowed to disassemble or repair

the machine without authorization.

(IV)

Daily maintenance

After completing the work, in addition to

cleaning of the machine, regular maintenance should be carried

out on the machine, for example, the fastening conditions of

various components should be checked, and the transmission

components should be lubricated, so as to ensure the normal

operation and service life of the machine. |

|

|

Product

Features |

|

|

1. Simple operation and convenient control,

the dough thickness, the rolling speed and the rolling direction

are adjustable, and the practicability is higher.

2. High-quality conveyor belt, smooth

conveying, and free of adhesion of dough.

3. Folding structure, small occupied area and

convenient storage.

4. Stainless steel body, high strength, clean

and hygienic, meeting the food safety standard.

5. Wide application, suitable for the food

industry. |

|

|

|

|

|

Stainless Steel Machine body

The

machine shell is made of thickened stainless steel materials,

making it firm and durable, achieving rust and corrosion

resistance, easy cleaning and long service life, and meeting the

food hygiene standard. |

|

Thickness Adjusting Handle

The

crust thickness can be adjusted freely according to the demands

of customers, and the handle can be pushed flexibly to adjust

the thickness of dough according to the scale marks on the

handle, ensuring the efficiency and precision of adjustment. |

|

Top Control Panel

The

speed regulator, the rolling direction control handle and the

emergency stop switch are integrated on the control panel,

easily achieving the functions of speed regulation, rolling

direction control and emergency stop and facilitating simple

operation. |

|

|

|

|

Conveyor Belt

The

high-quality conveyor belt is adopted to convey dough smoothly

and stably, and is durable, wear-proof, clean and safe, the

dough is not prone to adhering to the conveyor belt, and the

fuzzing phenomenon is effectively avoided during dough pressing. |

|

Steel Roller

The seamless steel pipe roller is subjected

to electroplating treatment, the skid phenomenon of the conveyor

belt is effectively avoided during use, the service life of the

roller is longer, and the precision gear bearing can run

smoothly. |

|

Foldable Structure

The conveyor belts on the two sides can be

folded upwards when the machine is not used, the occupied space

is effectively saved, storage and transportation are convenient,

and the practicability is greatly enhanced. |

|

|

|

|

|

|

Protective Covers

The

hollowed protective covers are designed for effectively

protecting the steel roller against damage and collision and

avoiding accidents. The hollowed design allows the operator to

observe the running state of the steel roller in real time. |

|

Control Switch

The

control switch can be turned on and off to start and stop the

machine easily and accurately, operation is easy and convenient,

the fault rate and maintenance cost are low, and the requirement

for operation skills is very low. |

|

Rubber Handles

The

rubber handles allow the operator to easily carry and move the

machine, making the machine more portable and practical. The

ergonomic structure greatly improves the user experience, and

the rubber material is resistant to wear and long in service

life. |

|

|

Operation

Method |

|

(I)

Adjust parameters.

1. Turn on the power and close the safety

cover.

2. Adjust the final thickness of the pressed

dough according to the desired thickness of puff pastry to be

made. When adjusting, use the handle to adjust the thickness,

press down the gear blade with your hand, and then move it to

the right to the appropriate thickness.

(II)

Place the dough.

Place the dough on the right conveyor

platform and sprinkle flour on the dough surface to prevent the

dough from adhering to the press roller or conveyor belt.

(III)

Rolling operation

1. Press the button or press the joystick

switch to convey the dough to the left platform, and adjust the

thickness again.

2. Repeat the above operation for 4-10 times

until the dough reaches the final thickness and the desired

number of layers, and the pastry operation is completed.

(IV)

Shut down and clean the machine.

After completing the operation, turn off the

power switch. Clean the machine carefully, and remove the

remaining dough and flour from the conveyor belt, the space

between the press rollers, and other parts of the machine. Note:

It is strictly prohibited to directly flush the machine with

water to avoid damaging electrical components. |

|

|

Product

Display |

|

|

|

|

|

Item Number (057238): 1 x Mini Commercial

Dough Sheeter 110V |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|