|

520MM Sticker Half

Cutting Machine |

|

|

|

|

|

|

|

The 520mm sticker half cutting

machine can be used for linearly cutting the surface layer of sticker

products or cutting the sticker products into strips, and can also be

used for dotting paper sheets. Stepless speed change can be conducted as

required in the cutting process, the maximum feed paper width is 520mm,

and the blade interval can be randomly adjusted within the width range.

The machine is easy to install and operate, convenient to use and high

in user experience and is widely suitable for printing adhesive roll

cutting, sticker cutting, ordianary paper cutting and so on. |

|

|

Product

Parameters |

|

Maximum Feed Paper Width: 520MM

(20.47'') |

|

Minimum Blade Interval: 12MM

(0.47'') |

|

Motor Power: 180W |

|

Power Supply: 110V 60Hz |

|

Rotating Speed: 50-300 R/Min |

|

Blades: 15 Sets |

|

Counting: Counter |

|

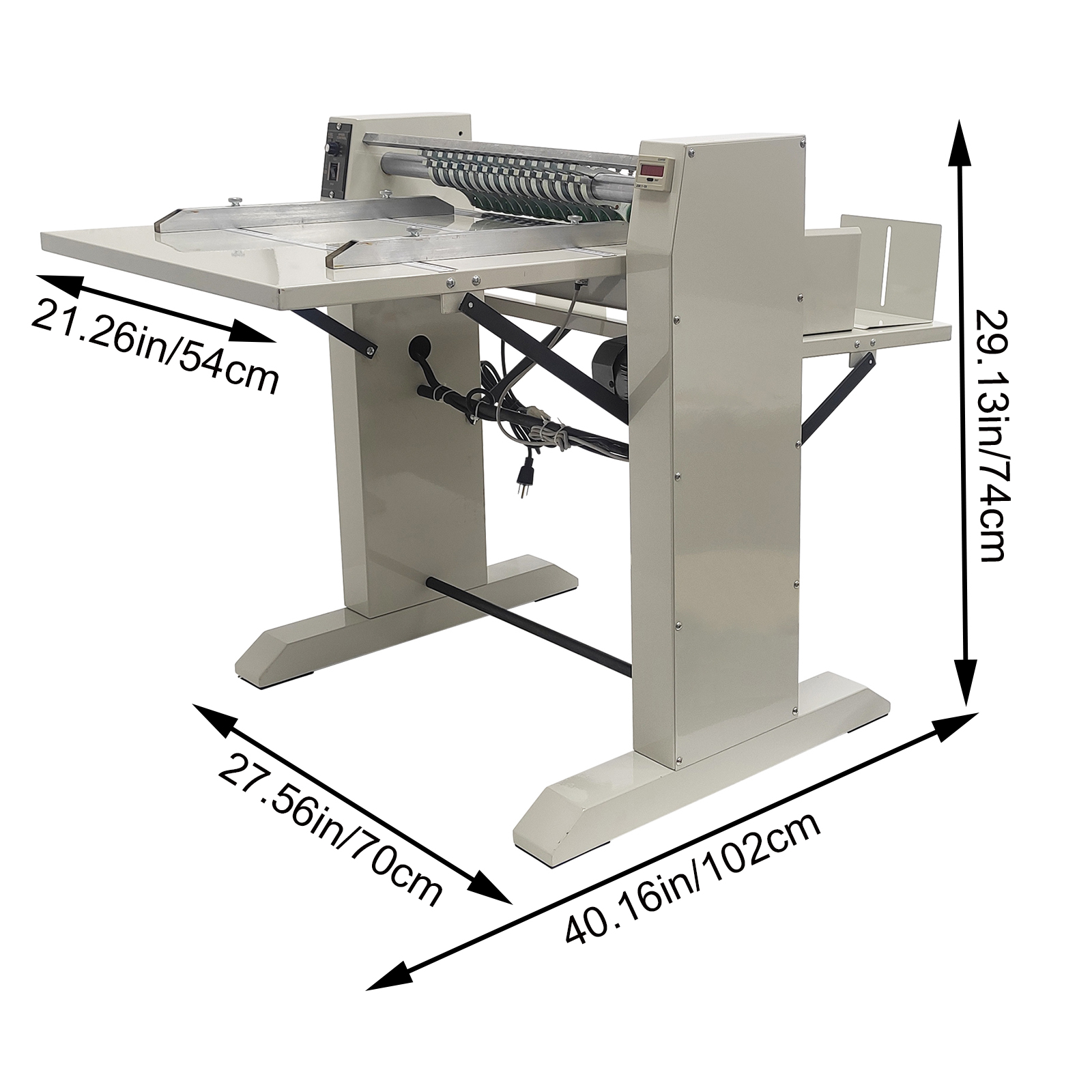

Size: 70x102x74cm

(27.56''x40.16''x29.13'') |

|

|

Product

Features |

|

The steel roller is subjected to

thermal treatment, is not prone to deforming, is hard and durable and is

long in service life. |

|

The tool rest bracket is processed

by numerical control machining, the stability of the bracket is

improved, the durability is improved, and the usage performance is

improved. |

|

|

The circular blade rolling cutting

technology is used, the minimum blade interval can be 12mm, the blade

interval can be randomly adjusted as needed, the practicability is

improved, and the user experience is improved. |

|

The speed of the roller can be

adjusted, the cutting speed can be adjusted as required, and the machine

is easy to operate and convenient to use. |

|

|

The leaning rulers are designed on

the two sides of the supporting platform, the distances between the

leaning rulers can be easily adjusted according to the size of paper

sheets, it is guaranteed that cutting is orderly and neatly, and the

working efficiency is improved. |

|

The machine is equipped with 15

paper press wheels and 15 circular blades, the blades can be adjusted

downwards or upwards by a wrench as needed, the paper press wheels can

well drive the paper sheets to enter, cutting operation can be smoothly

conducted, and sticker strips which are required by the user can be

easily obtained. |

|

|

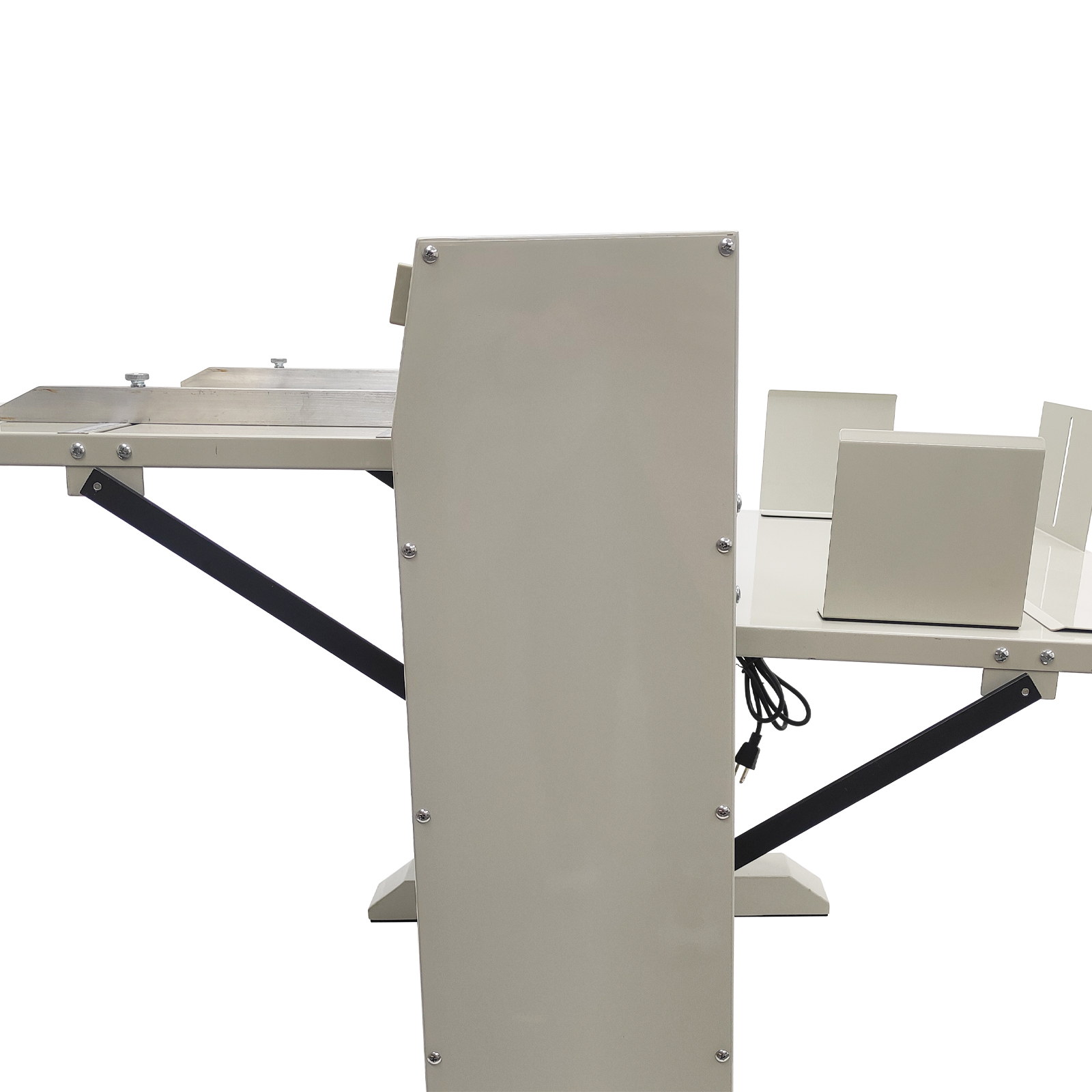

The front supporting plate and the

rear supporting plate are arranged on the two sides of the machine and

can be folded and unfolded through supporting rods, the paper sheets

which are fed into the machine and discharged from the machine can be

well supported and collected, and convenience is greatly improved. |

|

The two widened supporting legs

are installed at the bottom of the machine so that the machine can be

more stable, and the user can operate the machine safely and

comfortably. |

|

|

|

|

|

Operation

Methods |

|

1. The 110V socket is selected,

the machine is connected to the socket, the cutting speed is set, and

the machine is started. |

|

2. The sticker to be cut is pushed

to the roller, and the positions and the heights of the blades are

adjusted through the wrench until the quality requirements are met. When

the blades are adjusted, a piece of paper can be placed below the

blades, the blades are prevented from making contact with the roller,

and the roller can be protected. |

|

|

Notes |

|

1. The tool

rests are fastened on the steel rod, the screwing force needs to be

proper when the blades are adjusted, and the tool rests can be damaged

by excessive force. |

|

2. Each rubber

wheel is installed on the side of the corresponding blade to drive the

blade to work. |

|

3. The cover

plate needs to be opened every three months, and the tightness of the

belt needs to be checked. |

|

4. Do not touch

the blades, and the blades are very sharp! |

|

|

|

Item Number (122153): 1 x 520MM Sticker

Half Cutting Machine |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |