|

|

新建网页 3

|

TJ-150 type fish meat

mincer |

|

Overview: The fish meat harvesting

machine is a professional machine for processing fish meat to remove

bones. With the development of the market, fish has become an

indispensable part of people's lives. Whether at home, in

restaurants, or even in some leisure snacks, fish is a major food.

Nowadays, fish processed into paste is indispensable. The successful

development of the fish meat harvesting machine has brought a lot of

convenience to people's lives. Whether you are making fish balls,

fish fillings,., you only need a fish meat harvesting machine to

achieve it. For large-scale production, it not only reduces labor

costs but also improves production efficiency

|

|

Purpose:

The device can separate fish flesh and fish

bones, fish skin, and fish tendons in the fish body, achieving the

purpose of improving the utilization rate of materials and saving

labor costs. It also improves the economic value of low-value fish.

The mined fish flesh can be directly used for the production of

various surimi products: balls, fish noodles, fish gelatin,

fish dumplings, etc.

|

Main structure and

working principle:

- discharge port, fish paste discharge

port, drum, and fresh fish inlet.

- Small fish or medium-sized fish are

directly put in after being split open, while large fish need to

be headed, tailed, and chopped into before being put in. After

being squeezed through a low-speed, high-density stainless steel

sieve cylinder and conveyor belt, the fish bodies are taken out

with bones,orns, skin, and scales removed, and clean fish paste

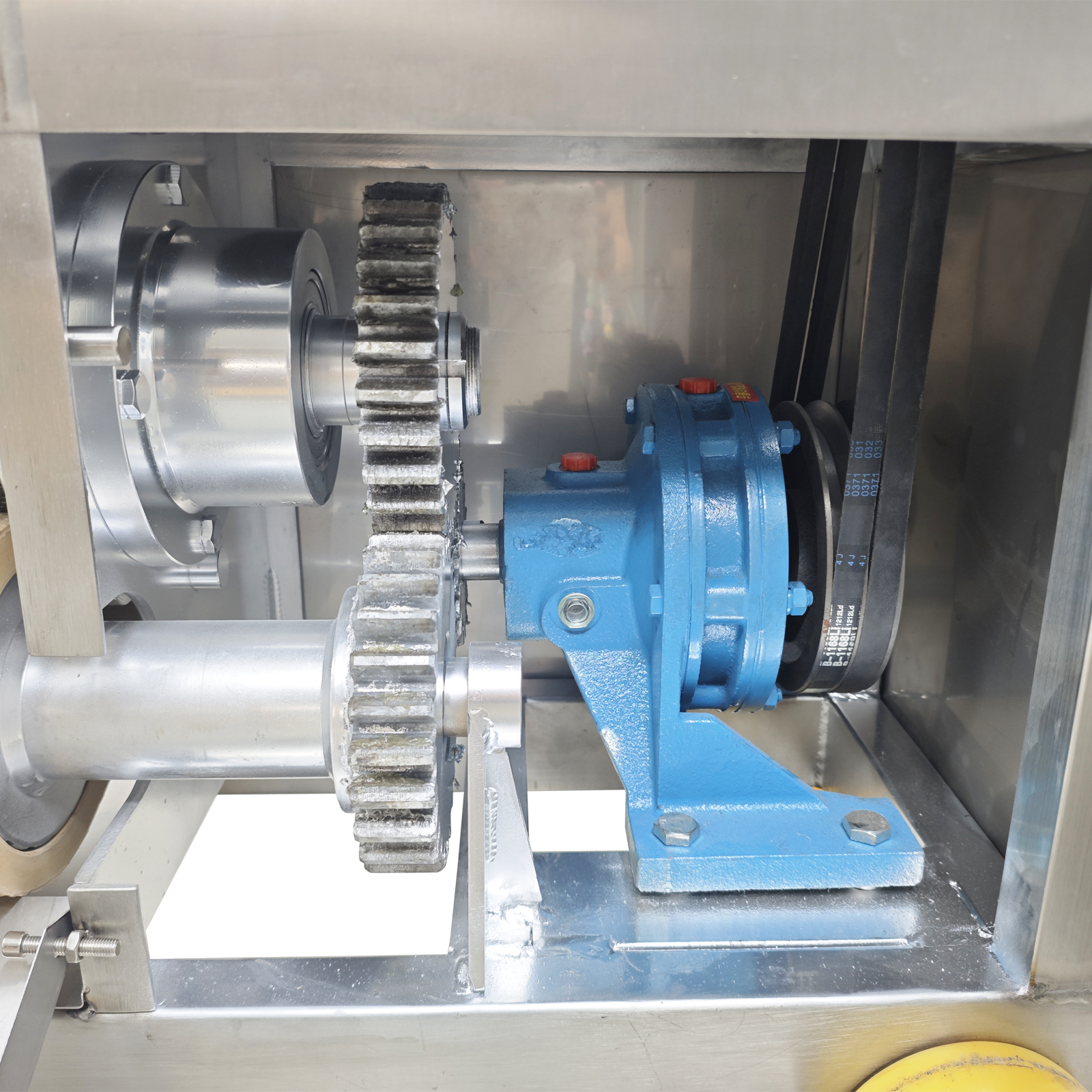

is extracted. The transmission uses a gearbox or reducer, which

has a large torque and stable low-speed operation overheating.

The machine is designed reasonably, easy to clean, and

efficiently extracts fish paste products, saving manual labor

for collecting fish paste and improving the economic value of

various cheap fish. It is also ideal for coastal areas to

process fish products.

|

Usage method:

- Plug in the power cord.

- Manually remove the head and internal

organs of the fish to be processed. For fish, it is necessary to

split the fish in half and wash it before putting the fish

pieces to be taken into the hopper (the flesh part faces the

taking bucket, and skin part faces the conveyor belt). The fish

is then carried by the conveyor belt into the working drum and

the pressure area between the conveyor belt. The separated fish

under the action of the pressure between the conveyor belt and

the working drum, is squeezed through the small holes on the

working drum into the inside of the working drum, and then

crushed fish flesh particles that have entered the taking bucket

are scraped into the receiving groove by the scraper inside the

working drum. The fish skin and bones are scraped off the bucket

by the scraper mounted on the machine and fall onto the conveyor

belt, which carries them into the collection groove at the

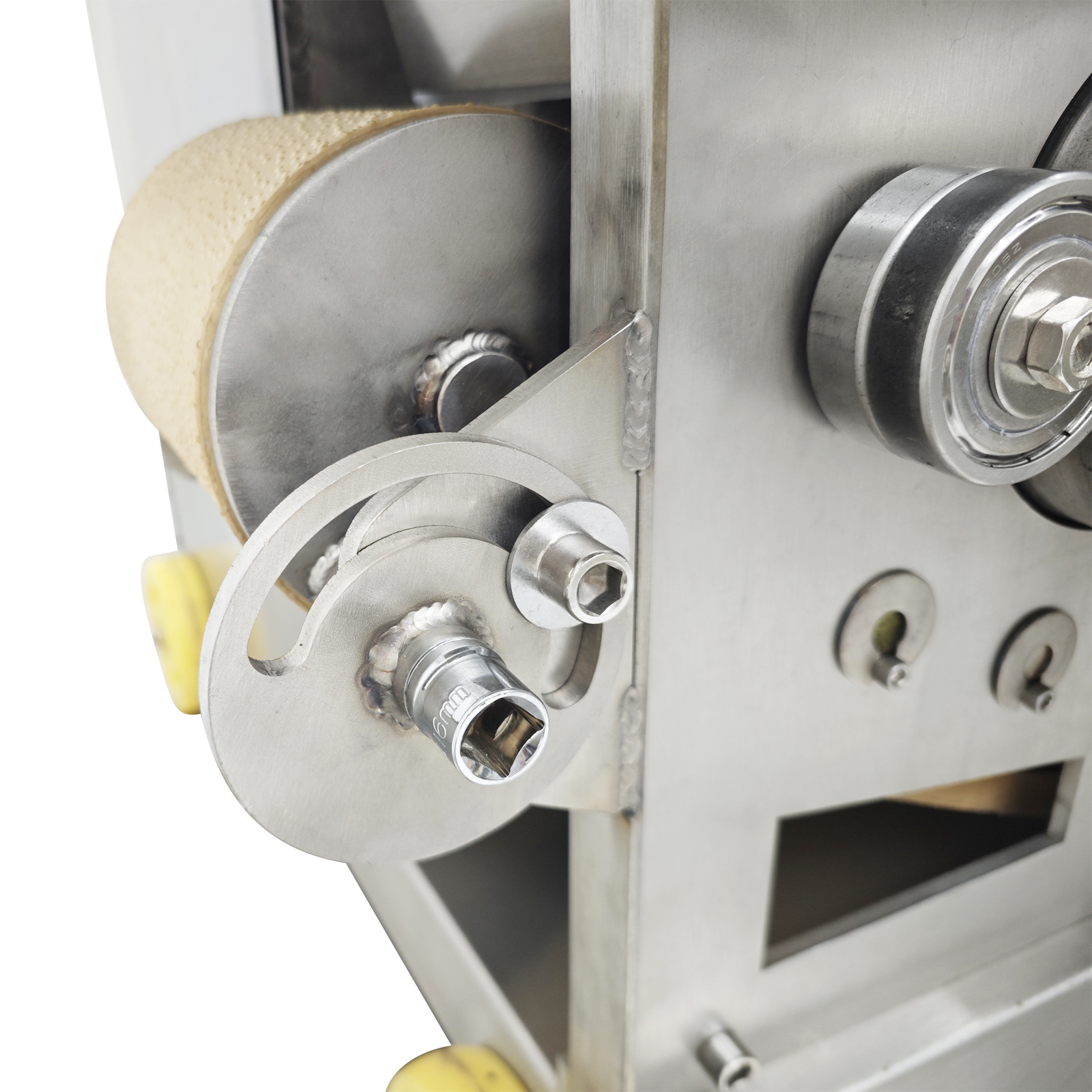

bottom of the fish meat separator. The pressure the conveyor

belt and the taking bucket is adjusted by the tensioning device

of the conveyor belt located at the head. The amount of

adjustment varies according to the different species fish. It

can be adjusted manually in production practice.

- The scraper outside the bucket is used

to separate fish paste and skin and bones, etc. During

processing, the scraper blade should be tensioned using scraper

tension knob to ensure that the fish skin and bones are

completely removed. The processed fish should have its head and

internal organs removed, and large fish must be cut in half The

fish skin should be facing the direction of the conveyor belt so

that the fish paste will enter the collection bucket and be

separated from the fish skin. Do not put your hand the machine

during processing.

|

|

Main

technical parameters

|

Material: |

High quality stainless steel |

|

Voltage: |

110V |

|

Power: |

1500W |

| Output per hour: |

200KG/H |

| Mesh size: |

0.106″(2.7mm) |

| Belt thickness: |

0.78″(2cm) |

| belt length outside |

48.82″(124cm) |

| Size of knife set: |

0.197″(5mm) |

|

Maintenance method:

- To ensure the normal operation of the

machine and extend its service life, maintenance work should be

strengthened during use. After use, wipe the fish meat machine

clean And regularly add grease to the transmission shaft, and

check the gear oil level, if the oil level is too low, add

engine oil in time.

- Conveyor belt replacement: After

long-term use, the conveyor belt may become longer or break, at

which time it is necessary to replace it a new one. First,

remove the tensioning balance crankshaft, then remove the other

three nylon shafts and the conveyor belt drive shaft. Place the

rubber convey belt inside the machine wall plate. First, install

the conveyor belt drive shaft, then install the other three

nylon shafts in order from top to bottom, and finally install

theing balance crankshaft and adjust the tension.

|

|

Other

details |

| The bottom is provided with a

discharge port, and the processed meat can be output from here.

Material discharge port size: 7.09″(18cm) |

|

|

The machine cooling outlet is an important

part to ensure the stable operation of the equipment. |

|

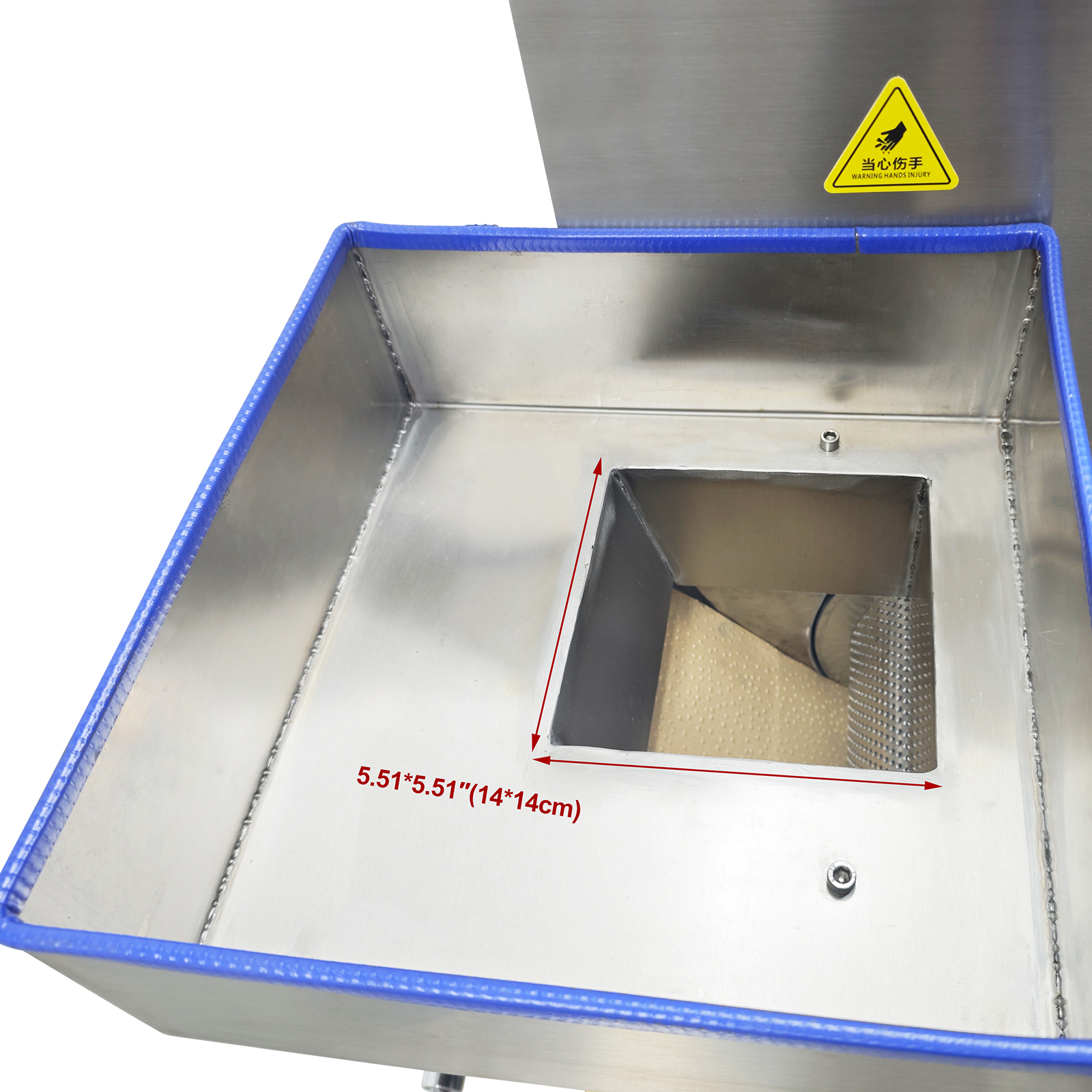

Top with a square feed inlet, it is

convenient to put in fish, vegetables and other raw materials.

Feed port size:5.51*5.51″(14*14cm)

|

|

|

Install the fixing bolts before use. |

| Equipped with multiple handles to assist in

installation. |

|

|

Use high-quality motors for stable and

powerful power, ensuring safer operation. |

|

|

Note:

Before first use of all new machines, wet

the drum belt with water to lubricate the belt. Take some slices of

potato or vegetables to clean holes of the drum screen. If the

machine is a three-phase motor, before connecting the power line to

the machine, first remove the lower spike plate, then turn on the to

prevent the motor from reversing and damaging the belt. If the motor

reverses, please rewire! After the forward rotation, turn off the

power and then re-install lower spike plate. |

|

Item Number:

TJ-150 type fish meat mincer-160330 |

|

You can make order

with no worry.

Any concerns just feel free to let us know, we'll reply in 24 hours

in normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on

the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the

consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical

support from us with low cost. |

|