|

|

|

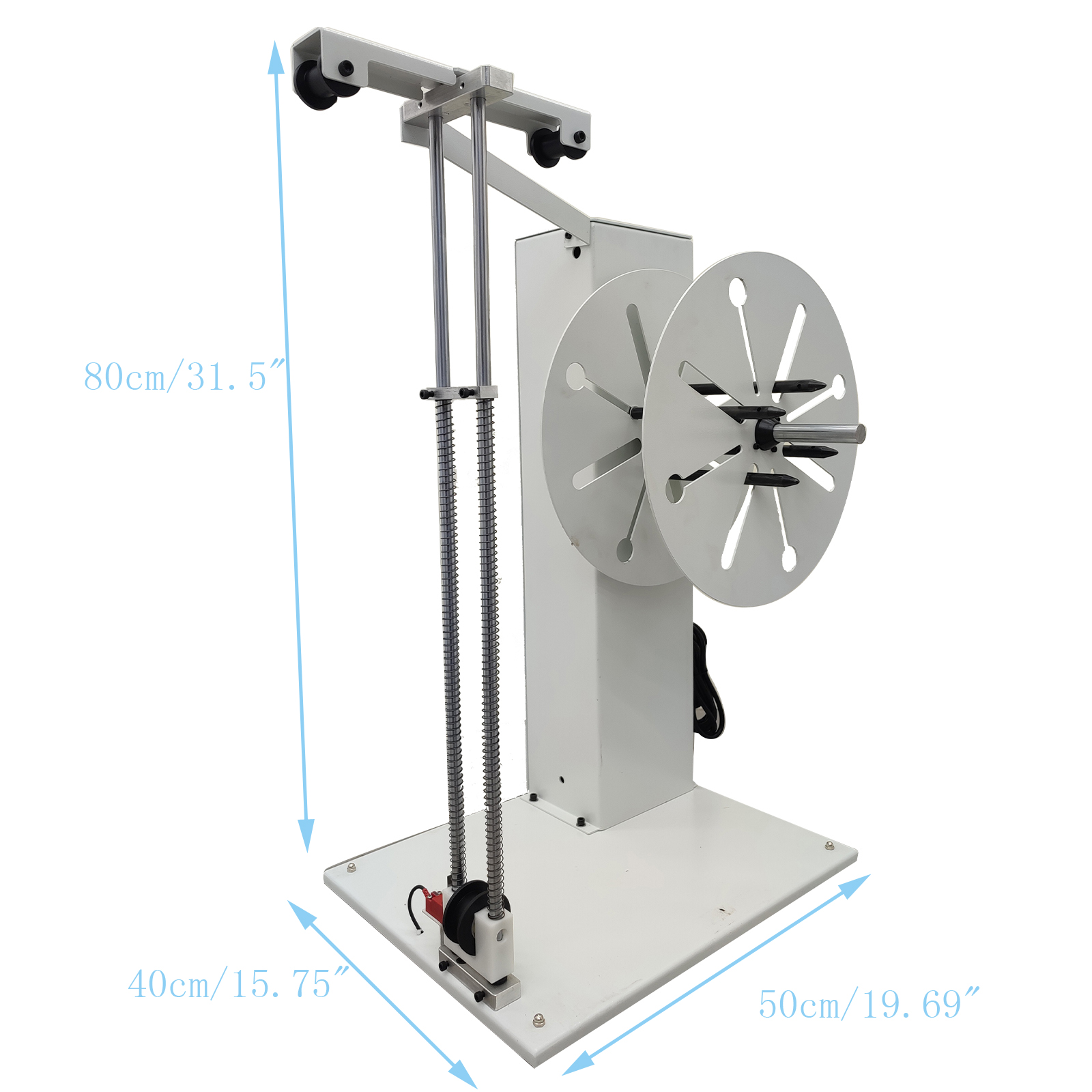

Fully Automatic Induction Pay-Off Frame Special Pay-Off Rack For Wire

Stripping 110V

|

|

|

|

|

|

|

|

The pay-off

machine is a wire and cable auxiliary

device which is

matched with the strander machine and plays a pay-off role.

|

|

Features

|

|

1. This

equipment is a fully automatic pay-off

machine, is matched with all kinds of fully automatic

terminal press machines, computer stripping machines and

fully automatic

winding machine, can make the matched host

wire without resistance, and can achieve synchronous wire feeding without manual

pay-off trouble

2. This machine is small in design,

convenient to install and easy to operate, and can achieve

pay-off operation of the spool, greatly reduce labor intensity and improve

production efficiency.

3. Suitable for

pay-off operation of a variety of peripheral pay-off

electronic wires, wires, sheath lines, steel wires and other

types of wires with reels and without reels.

|

|

Parameters

|

Voltage: 110V

Power: 120W

Line diameter: < 4mm

Clamping disc outer diameter: 400mm

Spool outer diameter: 20mm

Line speed: 1m/s

Wiring mode: lay horizontally

Weight: 15KG

Speed control mode: Manual speed control

Brake: electronic induction brake

Weight: 30KG

Product Size:

50*40*80mm

|

|

Attention |

|

1. The wire should not be

confused, the wire should be fixed and then unpacked, and the

wire should not be reversed, otherwise the line will be

scattered. When threading the wire, the wire should follow the

wire wheel. |

|

2. Clean the machine regularly

without special care. |

3. Do not touch the running

parts during operation.

Do not put the hands into the machine.

Do not allow people or objects to be located next to the running

parts of the machine.

|

|

Operation Method |

|

1. Take out one of the clamping coils, fix

the whole coil of wire on the spool, and then put the other

clamping coil on it, and fix it with the tools.

2. Insert the four positioning rods into the

electric coil to lock the flow of the wire. Insert the

positioning rods into the positioning slot of the cable clamp.

3. Thread the wire end into the porcelain

lead hole, then pass through the wire wheel, wind the wire in

the wire wheel in order, the wire cannot deviate from the groove

of the wire wheel, and then penetrate through the middle of the

wire wheel and the stop needle. Adjust the machine according to

the diameter of the wire, firstly, loosen the regulator to the

right, and put the wire into the wire feed wheel (do not pull

the wire into the wire feed wheel, which will damage the wire).

Then use the adjusting handle to press the regulator to the

left, adjust the space to the appropriate width, loosen and

tighten the wire, then turn on the power switch, and check

whether the wire feed wheel is idle or with the wire; If it is

idle, slightly tighten the regulator handle to the left until

the belt line runs normally (pay attention to seeing if there is

damage to the surface of the wire, you can go to the right and

slightly loosen the wire).

4. Thread the wire from the wire feed wheel

through the middle of the slide block and the fixed frame to the

entrance of the direction positioning rod to enter the automatic

computer wire cutting machine or other automatic equipment.

5. Turn on the switch of another motor, turn

on two speed control switches to conduct speed control according

to the speed of the equipment. The speed control switch can be

controlled according to the speed of the wire, 1-6 gear. |

|

|

Packing list

|

Host *1

Power cord *1

Pay-off reel *1 set

Auxiliary frame *1

|

|

Item Number: 220539

|

|

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost.

|

|