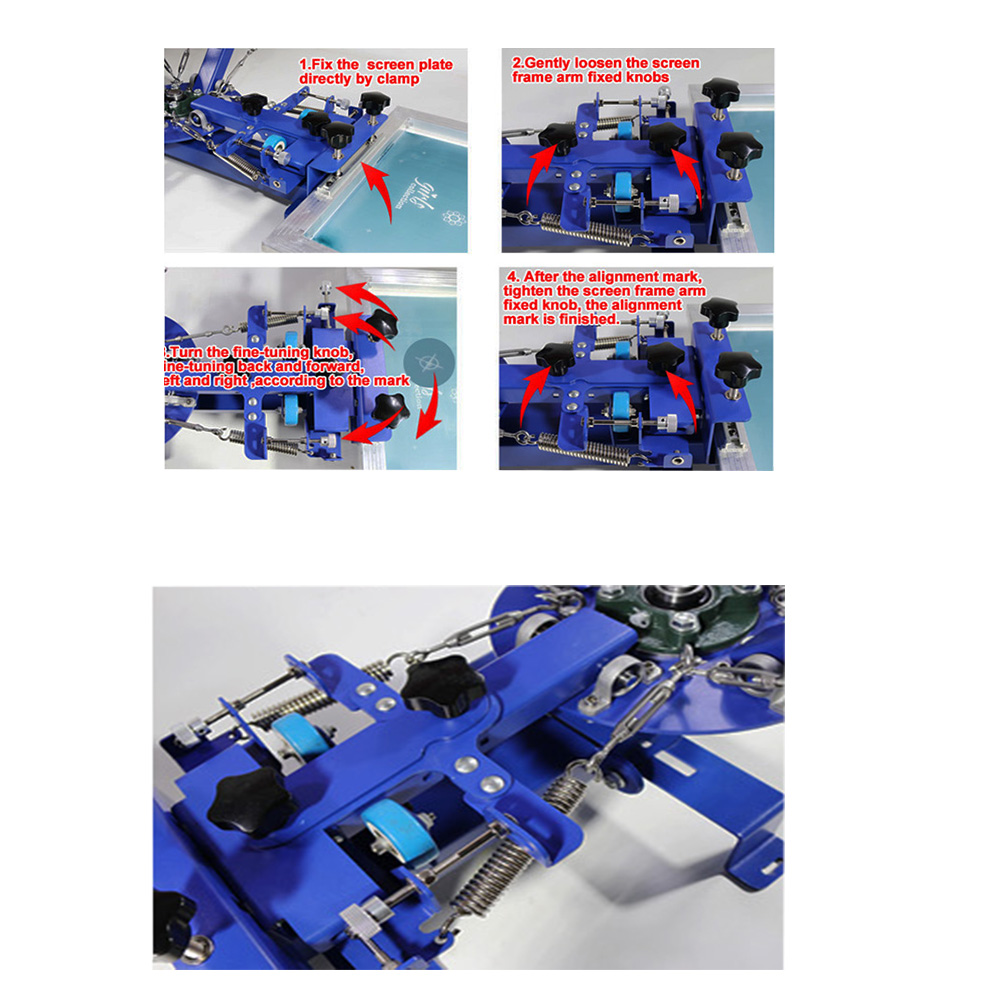

| 1:The chuck of the screen frame

can rotate at 360 degree.

2:Each screen frame arm is installed with 3 knobs to fine-tune the

screen plate, screen plate directly fixed on the clamp, loosen the upper

two fixed handle on the pallet arm , adjusting the screen frame back and

forward, left and right within 15 mm by the three fine-tuning knobs.

When the screen plate color alignment is finished, the upper two fixed

handle on the pallet arm can be tightened.

3: Each screen frame’s fixing device is equipped with precise

positioning wheel,when the positioning iron on the arm placed in

positioning wheel closely, it can ensure the printing precision .

4: Each screen frame’s fixing device is

equipped with big lock wheel, screen frame arm can easily fall into the

metal positioning wheel when touch the two big lock wheels ,and it also

can prevent the direct collision between the positioning iron and the

metal positioning wheel .

5:Each mesh frame fixing device is equipped with adjustable collet

height positioning knob and mesh frame lifting height adjustable knob;

6:According to the weight of the screen frame, spring tension can be

adjusted by the basket screws to achieve balance;

7:Screen frame chuck’s width is (10in) 25 cm ; It is suitable for

screen frame with outside size within (24 in) 60 cm and screen frame

with thickness size is within 4 cm (1.6 in) .

8: Screen frame chuck can be adjusted up to 5 cm (2 in)according to

the height of substrates;

9:Screen frame chuck knob fix the screen frame together with the

special aluminum alloy plate, and it can be fit closely and be more

stable;

10:The plate is fixed by the bottom iron sleeve to the plate arm, and

the plate can be moved up to 10 (4in) cm forward and backward as

required by printing.

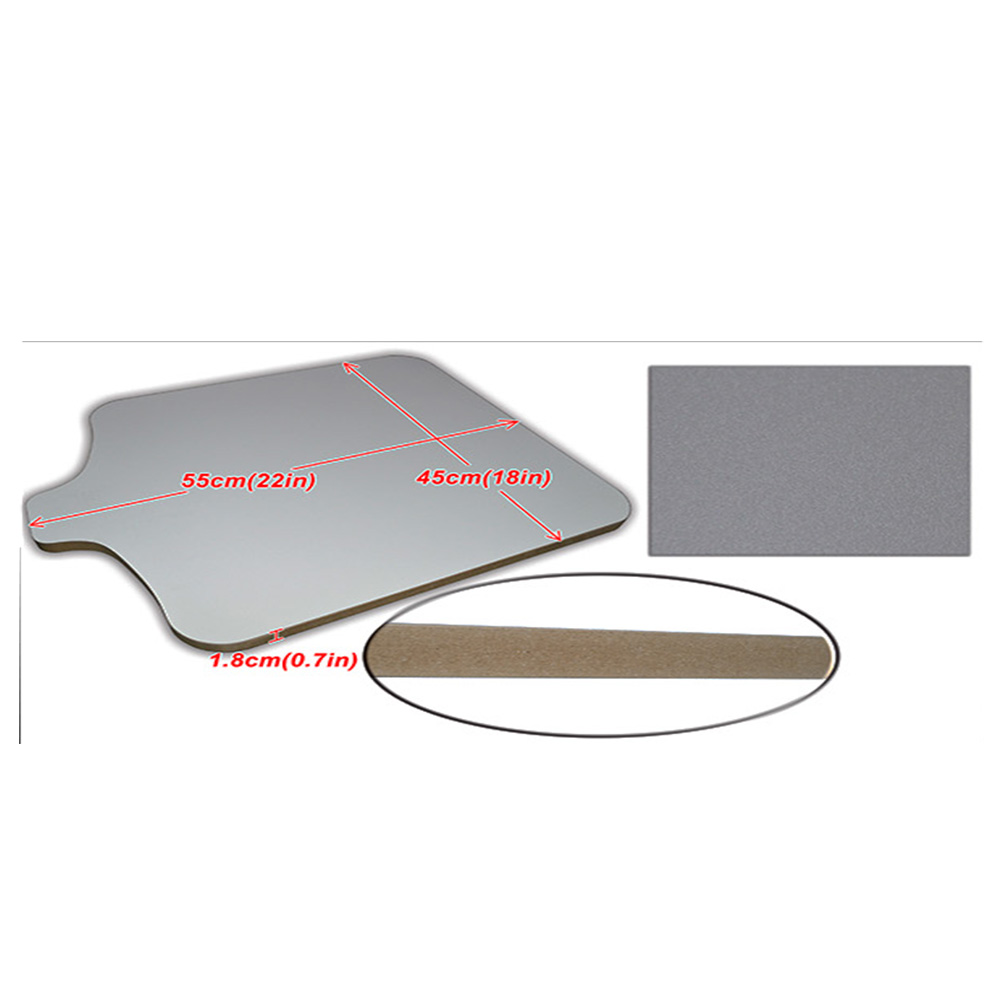

11:T-shirt type pallet of the machine is 55 cm (22 in) long, 45

cm(18in) wide, the thickness is 1.8 cm (0.7 in); Using furniture surface

melamine high density board, the surface with small pits, and it is more

suitable for printing T-shirt when scraping the pallet glue.

|