|

|

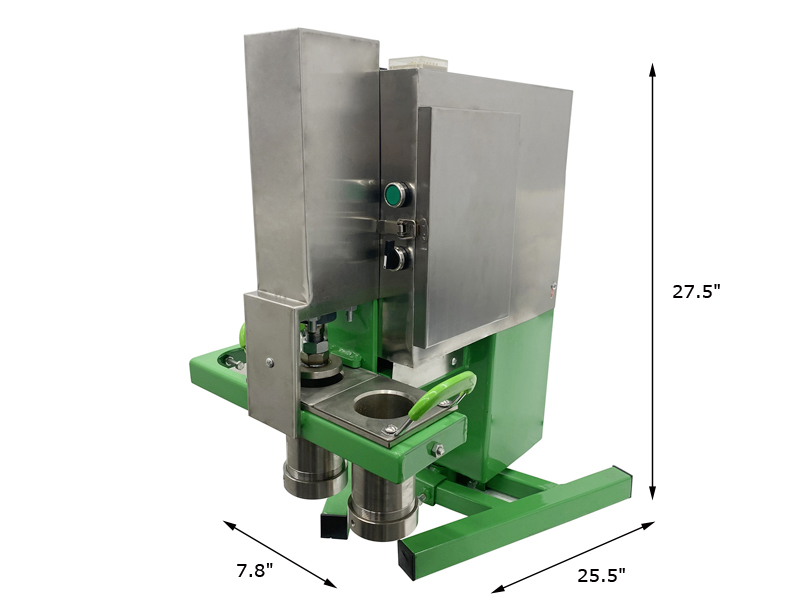

Electric

hydraulic noodle maker 110V

|

|

|

Product Overview |

|

This ramen

machine is a professional food processing device designed for making

fresh ramen noodles efficiently. It integrates mixing, kneading, and

extruding functions, suitable for home kitchens, small restaurants,

and snack bars. The machine features a compact structure, simple

operation, and adjustable parameters to meet different taste

requirements for noodle thickness and texture. |

Parameters |

|

Power Supply

|

110V |

|

Rated Power |

2.5kW

|

|

Capacity

|

2 bowls/10 seconds

|

|

Noodle Thickness

|

Round noodles:1.5mm/2.5mm/4mm

wide noodles:8mm/15mm

|

|

Operation

|

|

Precautions

-

Single-phase motors generate

static electricity during operation. Before using this machine,

connect the ground wire first.

-

Before starting the machine

each time, check that all position screws are tightened and no

loosening is allowed.

-

Use 6-7 liters of hydraulic

oil before use. Do not start the machine without adding oil.

-

Before use, check the wiring

head. Electrical components should be free of damage, leakage,

and oil leakage. Do not start the machine if not checked.

-

For the flour or starch used

in processing noodles or vermicelli, it should be mixed evenly

according to the filling ratio requirements. Do not allow dry

and hard dough pieces to be put into the machine to prevent

blockage of the outlet hole, causing the machine to overload,

damage machine parts, or burn the motor.

Preparation

Work

-

Check whether all parts of

the equipment are in good condition, whether the hydraulic

pipelines have oil leakage, and whether the mold is installed

firmly.

-

Add 6-7 liters of qualified

hydraulic oil to the hydraulic system (damage caused by starting

the machine without adding hydraulic oil is not covered by the

warranty).

-

Connect the equipment's

ground wire to ensure electrical safety.

-

Cut the dough without hard

lumps or dry powder into dough pieces that fit the mold size for

later use.

Startup

Operation

-

Connect the power supply,

turn on the power switch of the control panel, and the equipment

enters the standby state.

-

Put the prepared dough pieces

into the feeding area above the mold, ensuring the dough is

centered.

-

Press the pressure rod, the

hydraulic cylinder drives the mold to move downwards, and the

dough is extruded into noodles through the mold and

automatically falls down.

-

After pressing, lift the

pressure rod and cut off the noodles.

Shutdown

and Cleaning

-

After the work is finished,

turn off the power switch and disconnect the power supply.

-

Timely clean the dough

residues on the mold and the equipment surface. A damp cloth can

be used for wiping (note: avoid water entering the hydraulic

system and electrical components).

-

When not in use for a long

time, it is recommended to apply a small amount of edible oil to

the surface of the mold for rust prevention.

|

|

Precautions |

-

Safe Operation: When the

equipment is running, it is strictly forbidden to extend hands

or foreign objects into the pressing area. The single-phase

motor will generate static electricity during operation, so the

ground wire must be connected.

-

Material Requirements: The

dough must be kneaded evenly. It is forbidden to fill dry, hard

or lumpy flour into the feed inlet to avoid blocking the mold or

burning the motor.

-

Equipment Maintenance: Before

starting the machine each time, check whether all position

screws are tightened and whether the bearing lubrication is

good; avoid long-term idling after filling materials, and turn

off the power in time when stopping work.

-

Troubleshooting: In case of

abnormal noise, oil leakage, unstable pressure, etc., stop the

machine immediately for inspection. Non-professional personnel

are not allowed to disassemble the equipment without

authorization.

|

|

Special Reminder |

-

When kneading dough, the

ratio of 1kg flour to 0.5kg water must be strictly followed

(equivalent to the softness of handmade noodles). Only when the

kneaded dough reaches the right consistency and has a smooth and

bright surface can production and processing begin.

-

When pressing dough each

time, the dough cylinder must be pushed into place; otherwise,

the dough cylinder will be crushed or the machine will be

damaged.

-

Do not start the machine by

pressing the button without adding oil, otherwise the oil pump

will be damaged.

-

If static electricity is

generated during machine operation, such as a tingling sensation

in the hand, please switch the neutral and live wires of the

plug or socket, and the static electricity can be eliminated.

It is Strictly Forbidden to Start the Motor Before Adding Hydraulic

Oil.

Note: Starting the motor without adding hydraulic oil will cause

damage to the oil pump.

|

|

Detail Display |

|

|

No.1

Water-proof switch

Switch waterproof design, more safety. |

|

No.2

Five kinds of mould

Five molds can make five

different kinds of noodles. |

|

|

|

No.3

Stainless steel noodle barrel

Ramen bucket with handle,

more convenient and labor-saving. |

|

Product Display |

|

|

|

|

|

Item Number

(020430):Electric

hydraulic noodle maker 110V |

|

You can make order with

no worry.

Any concern just feel free to let us know, we'll reply in 24 hours

in normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on

the weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the

consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical

support from us with low cost. |

|