|

|

|

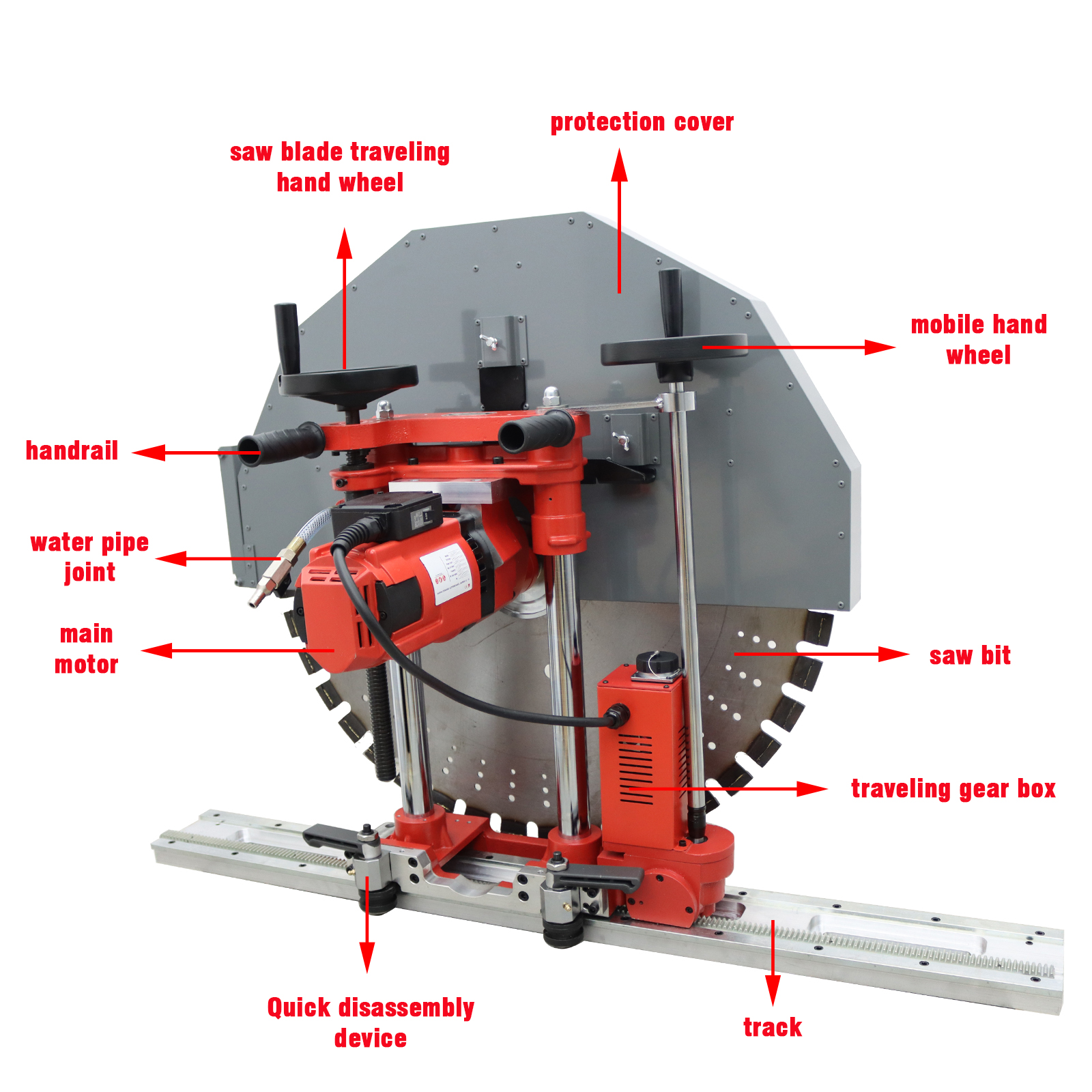

Quickly Disassemble

Track Concrete Wall Cutter |

|

|

|

|

|

|

|

|

Description |

Wall cutting machine is mainly used for building or old

building transformation,

reinforcement, change design, etc., can cut door holes, Windows or

elevator holes

and other large area wall cutting. The structure is non-destructive and

formed

once, which can avoid the damage of the traditional master knocking on

the building

structure. Save material resources, manpower, but also can save a lot of

time and

costs.

Wall cutting machine, the use of heavy industry grade double insulation

high power

motor and reducer, low failure rate, long service life, save maintenance

costs. The

special mechanical clutch protection device effectively prevents the

damage to the

machine and personnel due to misoperation. In addition to improving the

construction quality and speeding up the construction speed, the

semi-automatic

cutting machine also greatly reduces the labor intensity of the

operator.

Upgraded quick-release wall cutter, which greatly

improves labor efficiency and can

be operated in small Spaces (conventional machines are generally

installed from the

side when the main machine is installed, so that it cannot be cut to the

corners

when used). |

|

|

|

|

|

Parameter |

|

Rated Voltage |

220V |

|

Input Power |

5580W |

|

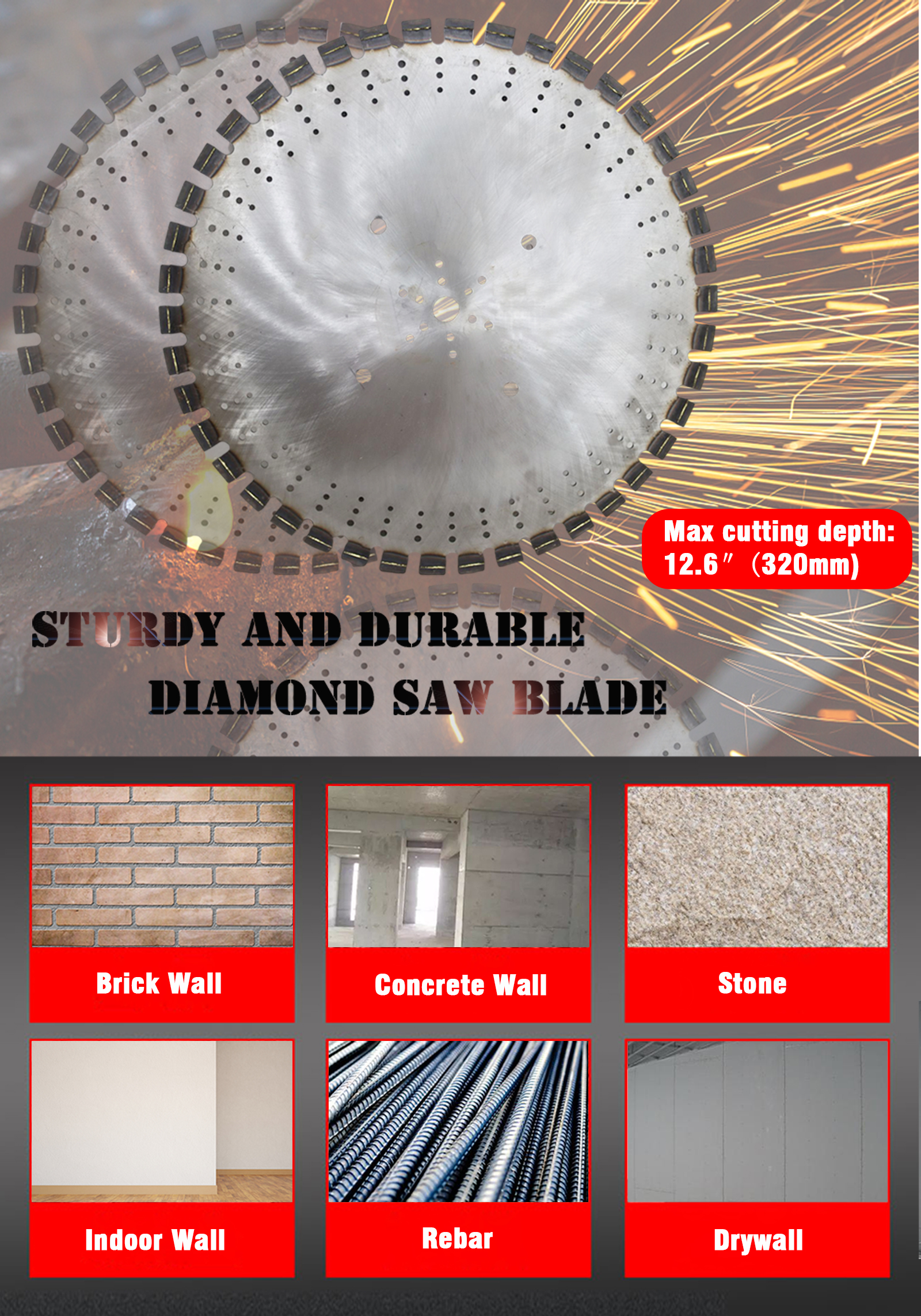

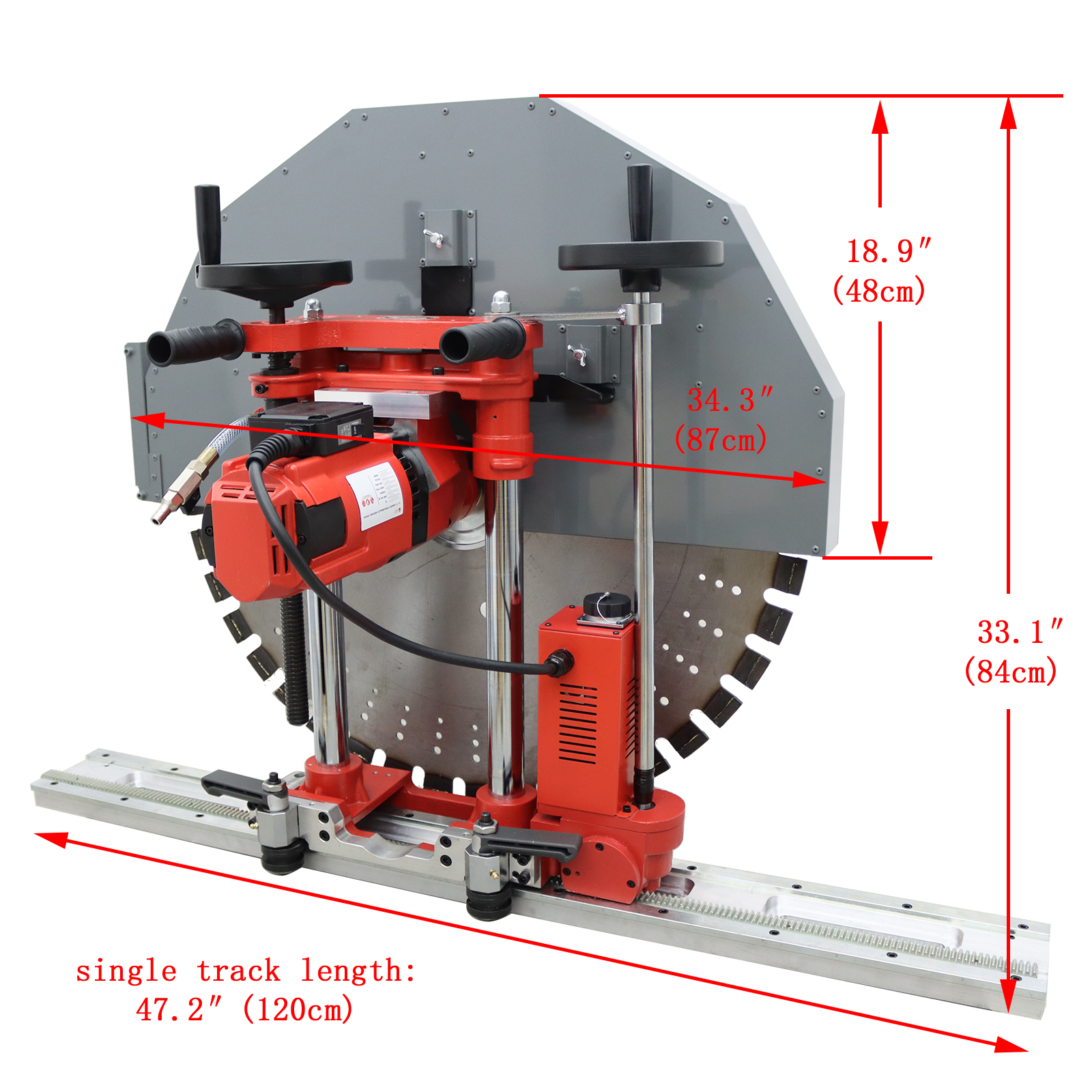

Blade Diameter |

31.5″(80cm) |

|

Max Cutting Depth |

12.6″(32cm) |

|

No-load Speed |

350rpm |

|

|

|

|

|

Detail |

|

Digital display control box

Digital display, real-time monitoring

of the host operation data, adjustable

speed, remote operation, safe and

durable. |

|

Stainless steel clamp

Thickened steel clamping plate, high

strength, wear-resistant and not easy to

deformation. |

|

|

Rotating handwheel Folding

rotating hand wheel, personality

design, easy to operate, all plastic

shell, high insulation strength. |

|

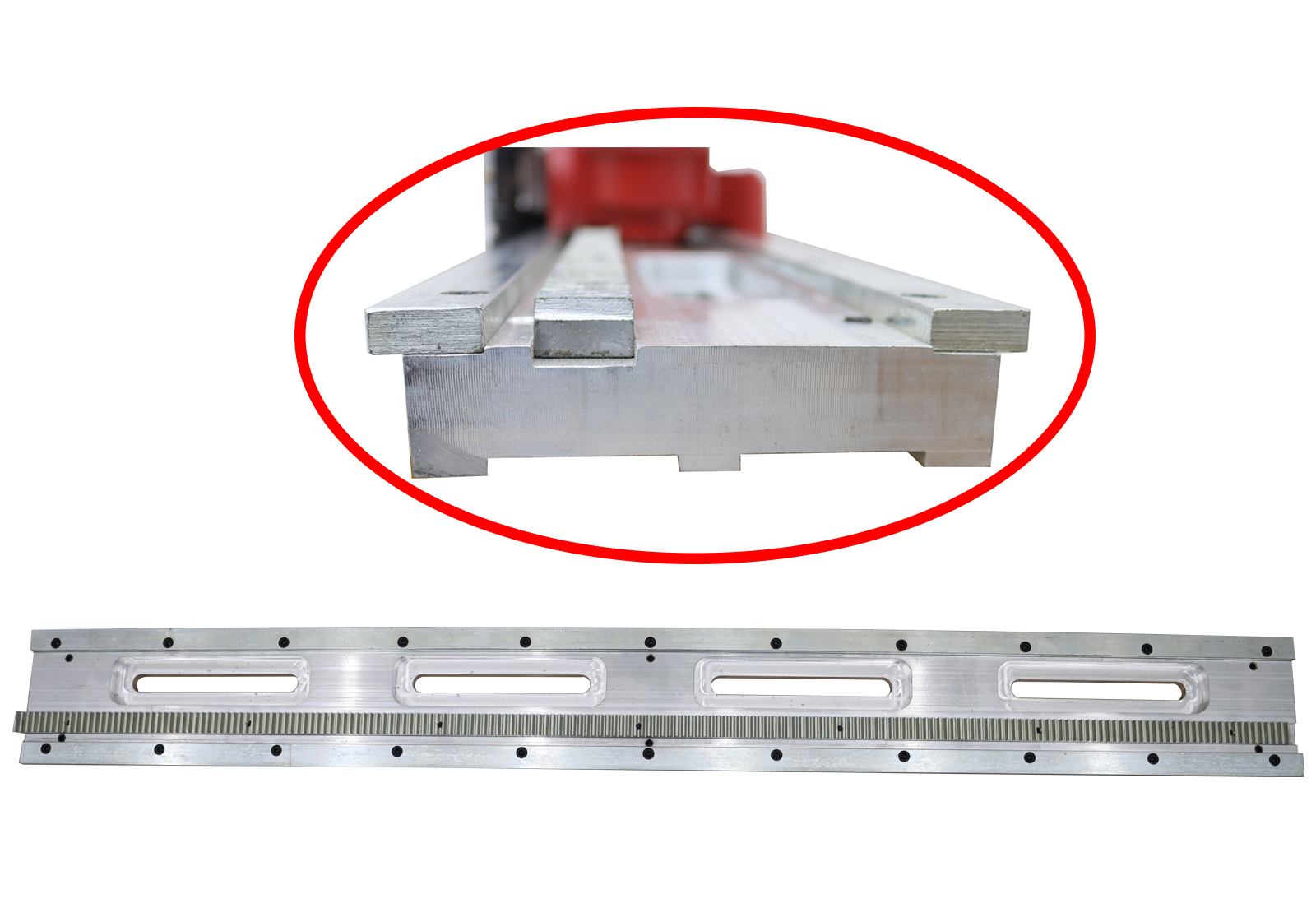

Aluminum profile track

Aviation grade aluminum profile refined,

high density, wear-resistant, not easy

to deformation or broken teeth, precision

run-in, teeth uniform, not stuck teeth. |

|

|

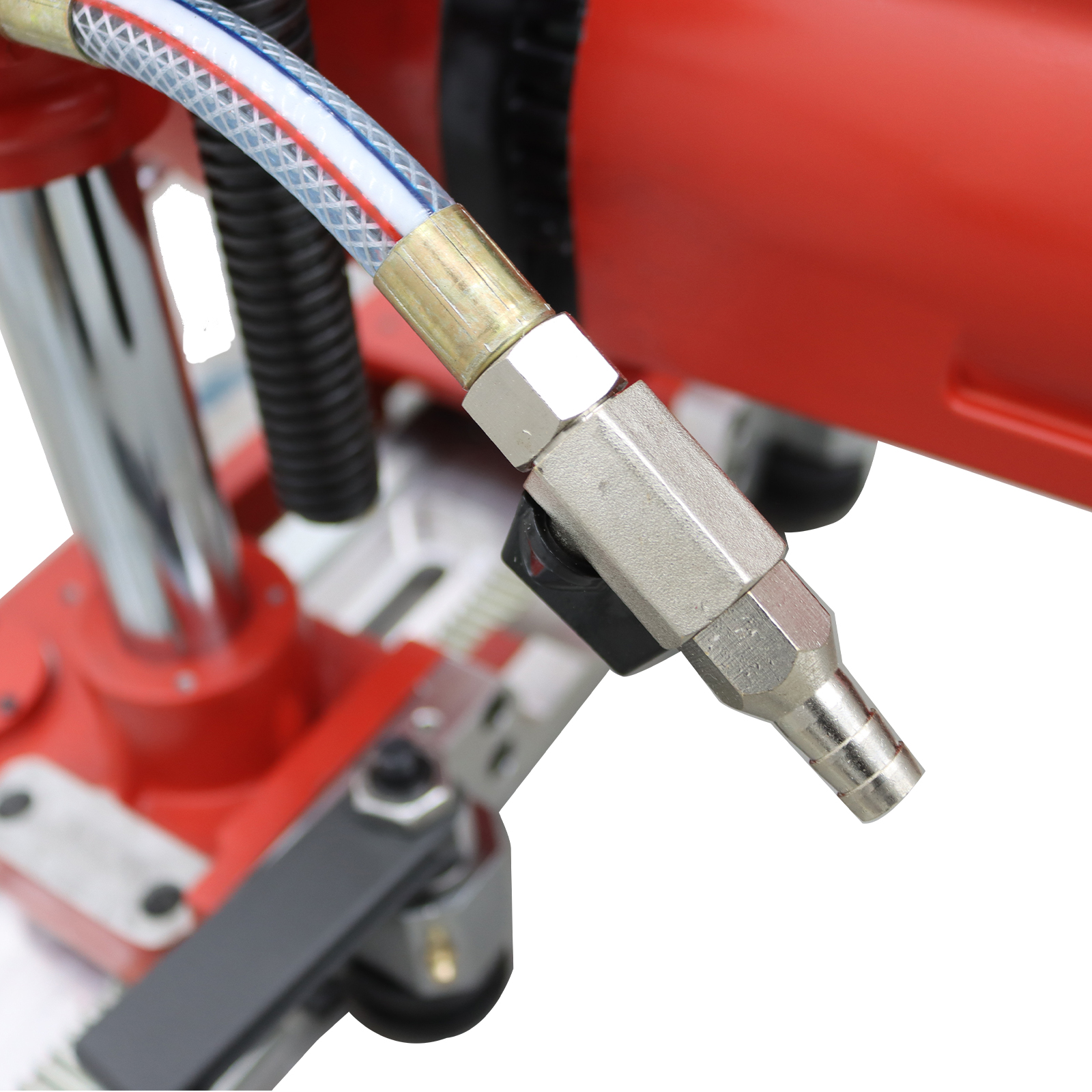

Water inlet valve Provide

water when cutting the next door

to prevent excessive temperature damage

to the saw blade. |

|

Quick connection plug Fast

connection between controller and

host, safe and convenient. |

|

|

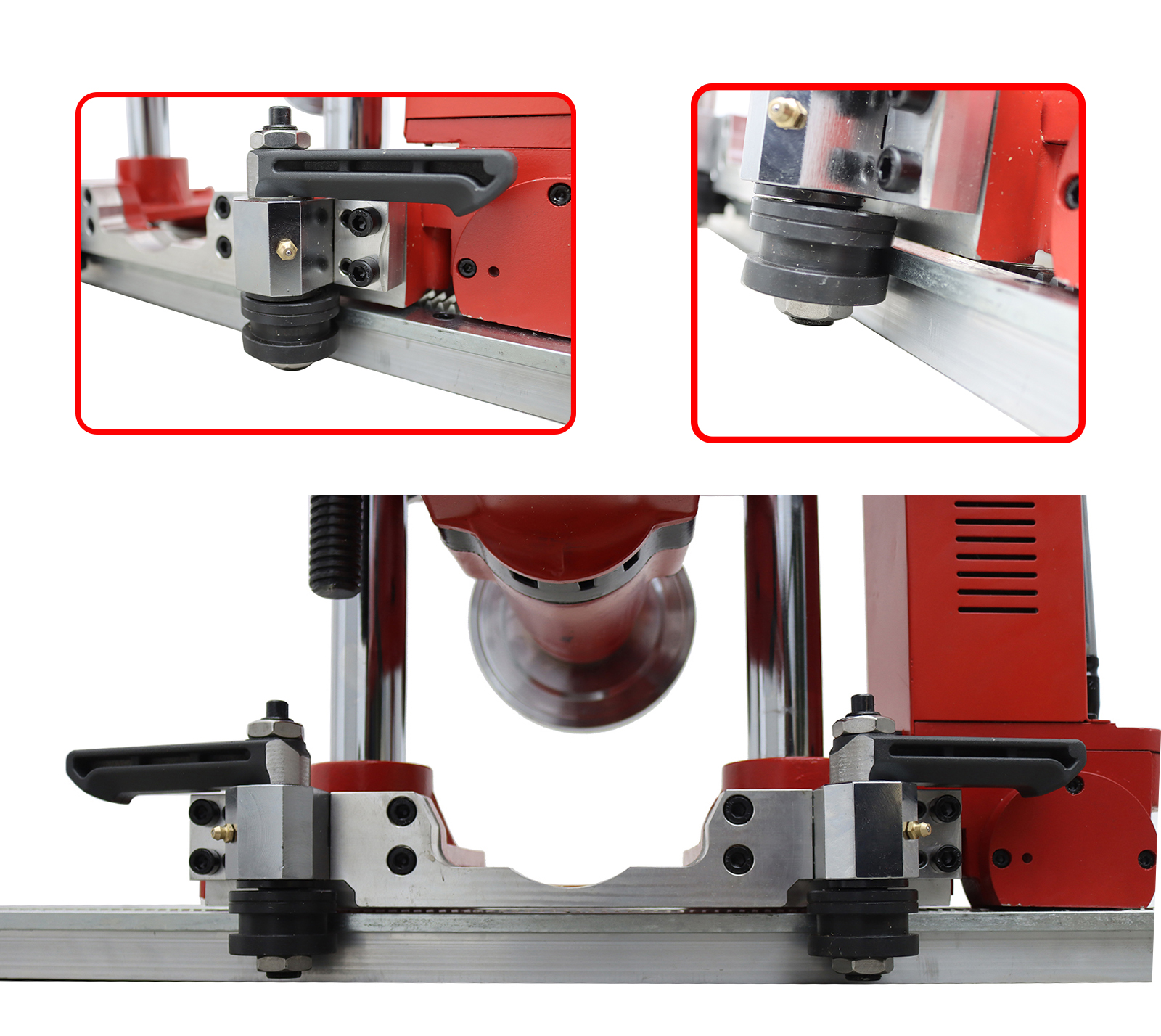

Quick disassembly of the base

Compared with traditional models, the

quickly disassembled base does not need

to be installed from one end of the

track, and can be installed from any

position on the track. Save time and

effort, convenient and fast. |

|

Precautions for use |

|

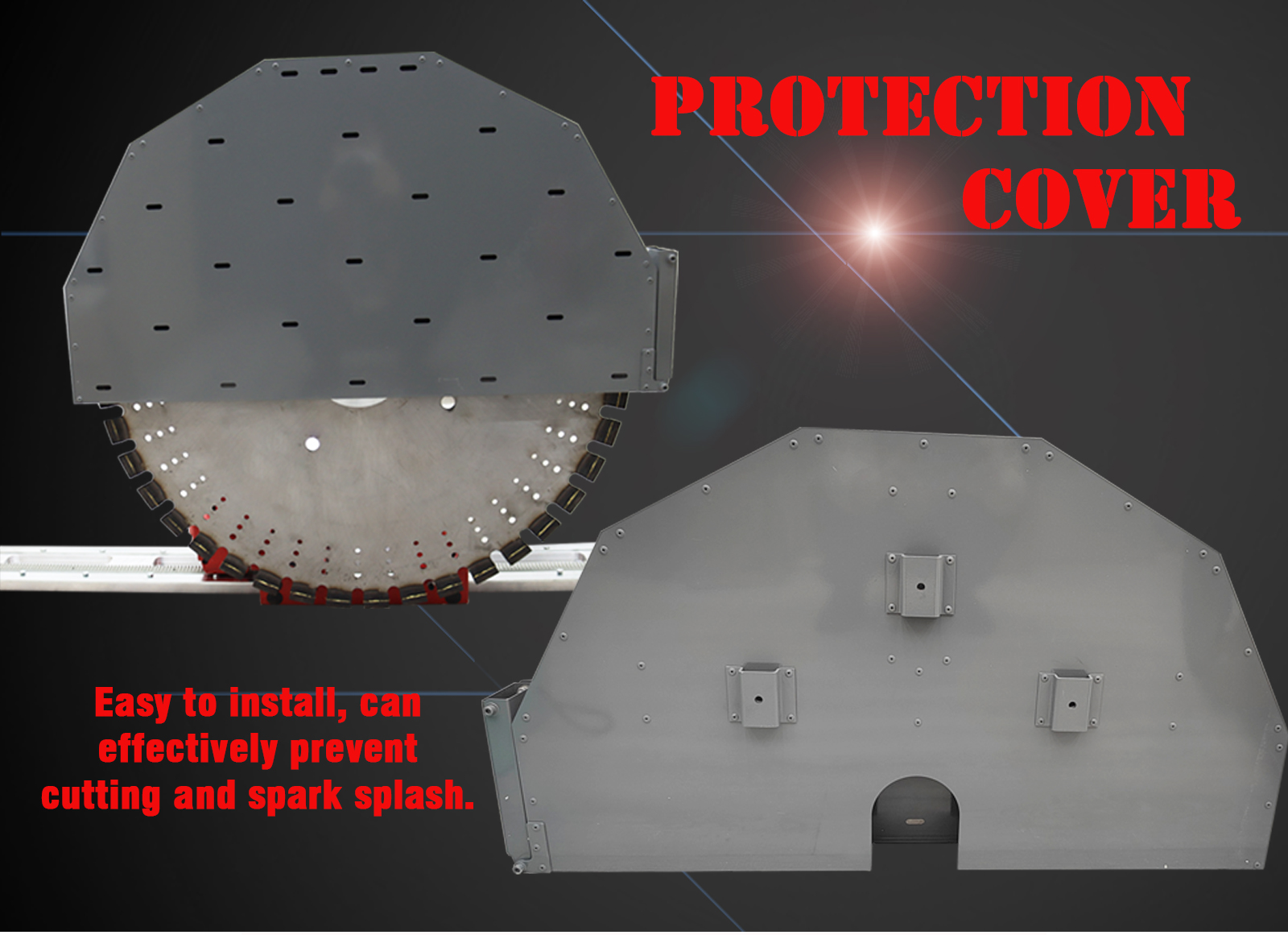

1. Installation and

fixation of the machine.

After installing the track, saw blade, and cover of the main machine,

grasp the top of the machine with your

hand and shake the machine vigorously from side to side. If the machine

shakes, it is necessary to adjust the

expansion screw on the rail and tighten it with a wrench. Cutting can

only be carried out when the machine is

not swayed laterally or longitudinally.

2.The motor inside should pay attention to waterproof.

If the motor inside water, will cause electric shock or motor burn.

3. Cutting must be cooled in the water inlet valve.

Because the overheated saw blade will shorten its

life, so in the cutting process, please pay attention to be

sure to

supply water in the inlet valve, in addition, please pay attention to

the use of recycled waste water,

otherwise it will

affect the flow of water, resulting in damage to water seals and other

parts.

4. Use a diamond

saw blade.

This cutting machine should use diamond saw blades, and other cutting

saw blades cannot be used instead of

diamond saw

blades.

5.Allow the saw

blade to fully rotate before starting cutting.

Turn on the switch and wait until the saw blade has fully rotated before

starting normal cutting.

6.Do

not touch the saw blade in rotation.

Do not touch the saw blade when the Angle is still rotating. This will

cause serious injury and is very

dangerous.

7.When

operating at heights.

If the machine is operated at a high altitude, please pay attention to

selecting a stable and secure location

for

installation.

8.When

the cutting machine is cutting laterally.

Because the machine must use cooling water during operation, it is very

dangerous for the main machine motor

to be above

during horizontal cutting, and vice versa. When the saw blade is above,

water will run into the

motor, which is very

dangerous.

9.When

an abnormal phenomenon is found.

In the process of cutting, if the saw blade stops or you hear an

abnormal sound, please turn off the switch

immediately.

10.Please

clean the machine after use.

In order to maintain the service life of the machine, please keep the

fuselage clean at any time after use. |

|

|

|

Item Number: Quickly Disassemble Track Concrete Wall Cutter 023513 |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us

with low cost. |

|