|

|

|

|

|

220V

101-0AB Digital Forced Air Convection Drying Oven |

|

|

|

|

|

|

|

|

|

Product

Overview |

|

The electric heating drying oven is an

efficient device for drying, baking, sterilization and solidification

and can be used for drying, heat treatment or constant temperature

experiments in the industrial and mining enterprises, medicine and

health industry, research and development institutions, etc. It can

achieve accurate control over the temperature, quick drying, power-off

protection, timing, uniform heating and other functions. |

|

Product

Parameters |

| Model |

101-0AB |

|

Voltage |

AC220V |

|

Power |

1.0KW |

|

Shelf load |

15KG |

|

Temperature range |

RT+10-250℃ (the

highest temperature: 300℃) |

|

Temperature fluctuation |

±1℃ |

|

Temperature of working environment |

5-40℃ |

|

Relative humidity of working environment |

<90% |

|

Exterior size (L×W×H) |

65*45*52cm/25.6*17.7*20.47 inch |

|

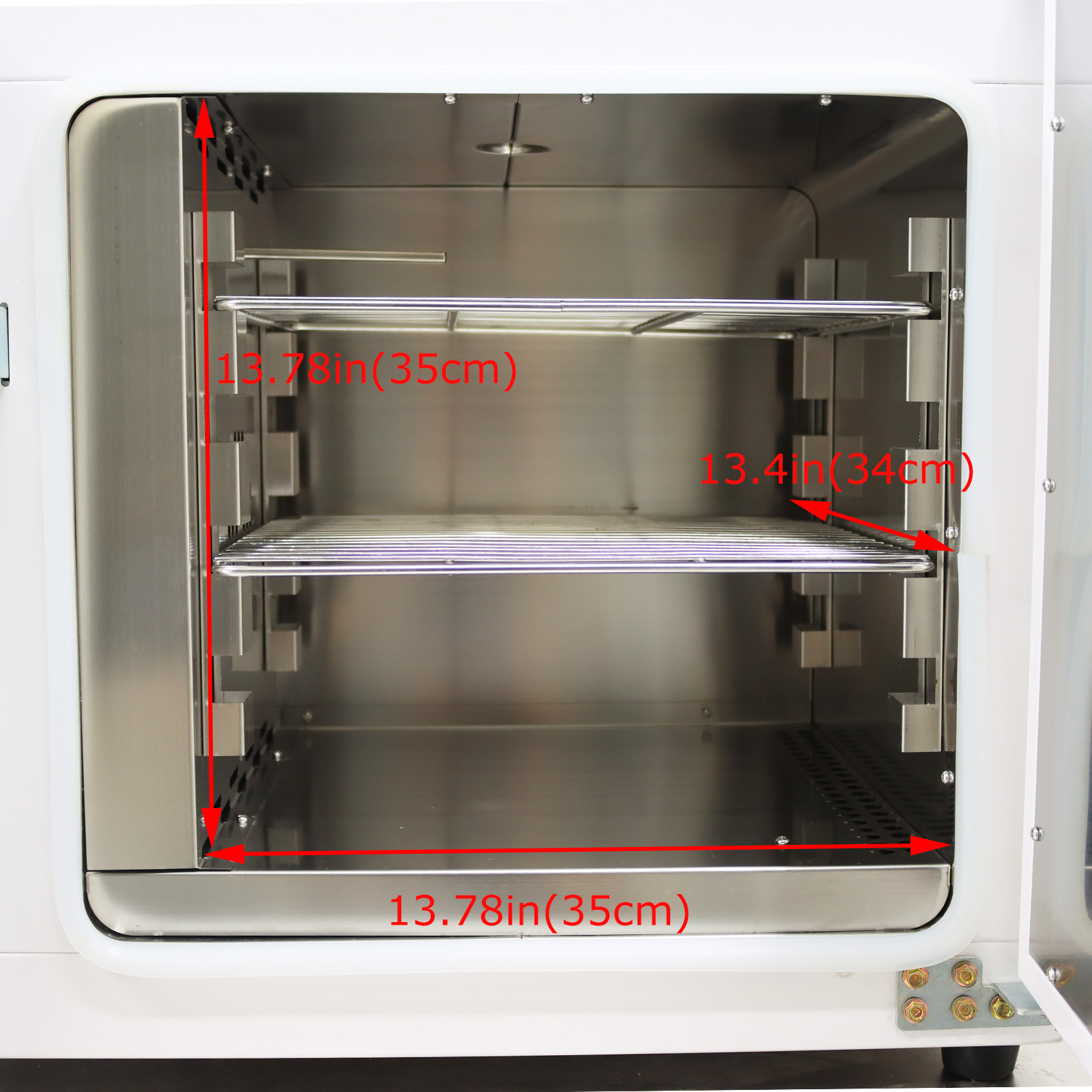

Inner chamber size (L×W×H) |

35*34*35cm/13.78*13.4*13.78 inch |

|

|

|

|

|

|

Product

Features |

|

|

|

External Structure

The shell of the whole machine is made of high-quality

cold-rolled steel sheets and processed by the electrostatic

spraying technology, so that the shell is firm and durable, has

rust resistance and scratch resistance and is environmentally

friendly and practical. The new appearance design is adopted,

round corners are designed at the four corners of the machine

body, so that the drying oven is attractive and elegant.

|

|

Intelligent

Controller

The PID intelligent temperature control instrument is adopted

for accurate temperature control. The digital display mode is

used, the temperature fluctuation can be ±1℃, the temperature

deviation is automatically corrected, over-temperature power-off

protection is achieved, and the timing function can also be

fulfilled. The multiple functions are integrated, and the

practicability and control accuracy can be higher.

|

|

Fan Switch

The fan switch has 3-grade speed adjustment capacity, the

fan speed can be adjusted more flexibly as needed to meet

different drying requirements, energy saving and noise reduction

are optimized, the influence of the hot air on the fan can be

reduced, and the operating convenience is also improved.

|

|

|

|

|

Door Handle

The drying oven is equipped with a novel latch door

handle, the oven door can be opened and closed easily and

conveniently, sealing is better and more stable after the door

is closed, the practicability is greatly enhanced, the user

experience is well improved.

|

|

Observation

Window

The drying oven is equipped with a double-layer tempered glass

observation window, real-time monitoring can be achieved, the

sample state can be observed clearly and visibly, and

anti-fogging treatment is achieved through the double-layer

hollow structure. The safety protection performance is good,

explosion protection and impact resistance can be achieved, and

heat insulation and sealing performance are excellent.

|

|

Sensor

The drying oven is equipped with a high-precision sensor which

can monitor the internal temperature in real time and feed the

data back to the PID controller to achieve dynamic adjustment of

the temperature. The temperature measurement precision is high,

the long-term stability is good, the aging resistance is high,

the adaptability is high, and the sensor can cooperate with the

drying oven perfectly.

|

|

|

|

|

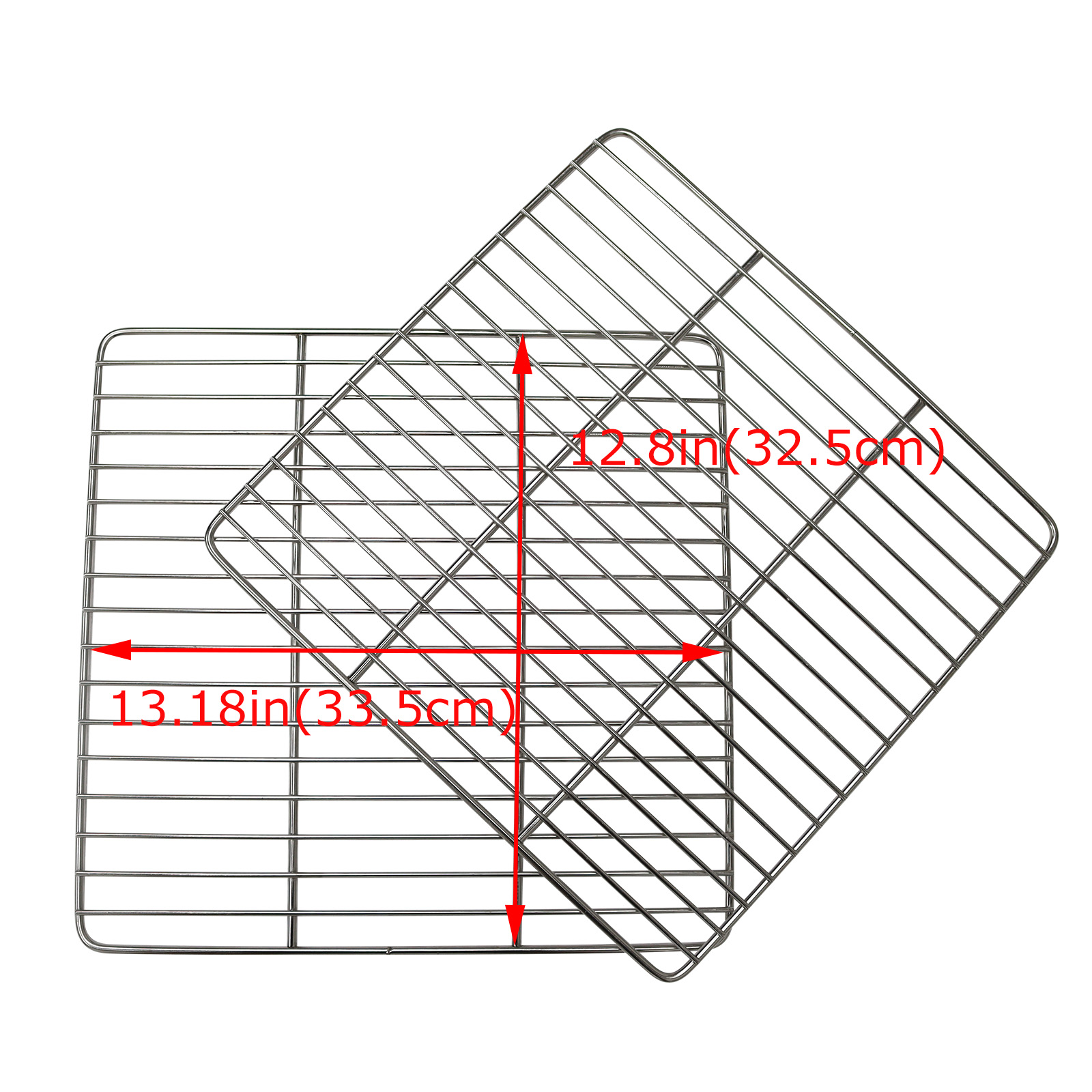

Shelf

Two shelves are installed in the stainless steel inner chamber

detachably, the distance between the shelves can be freely

adjusted, the space utilization rate is improved, and the

shelves can well adapt to the high temperature environment. The

grid design can optimize the hot air circulation and ensure that

the hot air can pass through the grid, no dead corners exist,

and the drying uniformity is higher. |

|

Hot Air

Circulation

The rotary type hot air circulation system is adopted for

powerful hot air and uniform heating. The temperature uniformity

is excellent, and the fan drives the hot air to flow to conduct

forced air convection so that the temperature difference in the

areas can be controlled. Multiple air ducts are designed, the

hot air can cover all the regions, and the drying efficiency is

obviously improved. The heat utilization rate and the system

reliability are higher.

|

|

Sealing Strip

A synthetic silicone sealing strip resistant to high temperature

is embedded into the oven opening, the oven door and the oven

body can be closely combined through the sealing strip, the heat

loss can be effectively prevented, the internal temperature

uniformity and stability are ensured, and the drying efficiency

is improved. The sealing strip has good chemical resistance,

elasticity, durability and adaptability.

|

|

|

Attention |

|

1. The temperature of the working

environment should be 5-40℃,and the relative humidity of the working

environment should be smaller than 90%.

2. It is strictly

prohibited to use the device in the experiments of inflammable and explosive

and highly toxic and corrosive substances.

3. Be sure

to place the device on

the dry platform or ground, and keep >50cm distance away from the wall.

4. Please read the operation manual

carefully before operation.

5. Ensure that there is no

visible damage to the exterior of the machine and the machine is in

good condition before use.

6. Do not touch the running

parts during operation. Do not put your hands into the machine. Be

careful of heat burns during use.

7. Turn off the power when

the equipment is not in use, and keep it dry and clean. |

|

Application |

|

As a professional drying device, the

digital forced air convection drying oven can be widely applied to the

laboratory and scientific research field, the medicine and food field,

the electronic engineering field, the chemical engineering and material

field and other industrial application. |

|

|

|

Operation and using |

|

1. Please read the operation manual

carefully before starting the machine.

2. According to the need, put the

experimental items on the tray, turn on the power, turn on the switch,

set the required temperature according to the intelligent instrument

operation instructions.

3. Temperature and time settings:

Press the "Set" button, and the controller runs in the temperature setting

state. Press the "Set" button again, the

controller runs in the time setting state. In the setting state, you can

use the "◀" "▼" and "▲" buttons to get the

required settings. Press the "set" bution again, it returns from the

setting state and the settings are saved automatically.

(1) If the time is set as "0", the

controller will run continuously, the display window of "SV" will

display the set point temperature. If the time set value is not equal

to "0", the timer starts to time when the measuring temperature reaches the set

point temperature, and the display window of "SV" will display the runtime.

(2) If En =0, when the runtime is over,

the "SV" window will display "End", the buzzer will make a sound for 30s,

and

all outputs are off.

(3) If En =1, when the runtime is over,

the "SV" window doesn't show "End", the buzzer makes a sound for 30 seconds,

the

temperature continue to be constant temperature. After the end of operation,

long press "shift/ run" button for 3 seconds, and the timer

operation can restart.

4. When the temperature alarm is given, the buzzer

will make a sound, "ALM" light is on. If a change exists in temperature setting and

over-temperature alarm, "ALM" lights up, but the buzzer makes no sound.

5. When the buzzer makes a sound, it can be

muted by pressing any button.

(1) "◀"button: In the setting state, it can shift the set value by

pressing the button.

(2) "▼"button: In the setting state, it can reduce the set value by

pressing the button. If press and hold the button, the set value will

reduce continuously.

(3) "▲"button: In the setting state, it can increase the set value by

pressing the button. If press and hold the

button, the set value will increase continuously.

(4) In setting state, the controller will return to the run state if no

any key press is conducted in one minute.

If the display window shows ''----'', it indicates the fault of

temperature. |

|

Product

Display |

|

|

|

|

|

Item Number (160110): 1 x

Forced Air Convection Drying Oven 220V 101-0AB |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |

|