|

|

3T Adjustable

Welding Turning Roller 220V |

|

|

|

|

|

|

|

|

Product

Overview |

|

The welding roller rack is an

auxiliary device for supporting and rotating cylindrical or annular

workpieces, generally cooperates with welding machines to achieve

efficient and automatic welding of the workpieces. Two driving motors

are adopted to drive the polyurethane wheels to rotate synchronously so

that the workpiece can be driven to rotate at the uniform speed, the

welded seam can be located at the optimal welding angle all the time,

and the welding quality and efficiency can be greatly improved. |

|

Attention |

|

1. Machine should be placed at

the dry, clean and ventilated position, and the operation of the machine

placed at a horizontal position should be smooth. Keep away from

flammables and explosives. |

|

2. For safety reasons, the

machine must be connected to a reliable safety grounding device and must

have three feet with ground connection. |

|

3. Unplug the power cable/cord if

the machine will not be used in a long time. |

|

4.The color of the power cord may

vary depending on the factory batch. |

|

5. A battery

needs to be installed in the remote control, and the customer needs to

prepare the battery by himself. The battery model is AA battery. |

|

6. Every time the

machine starts, the remote control needs to be set to the lowest speed

in order to achieve normal operation of the machine. |

|

Product

Parameters |

|

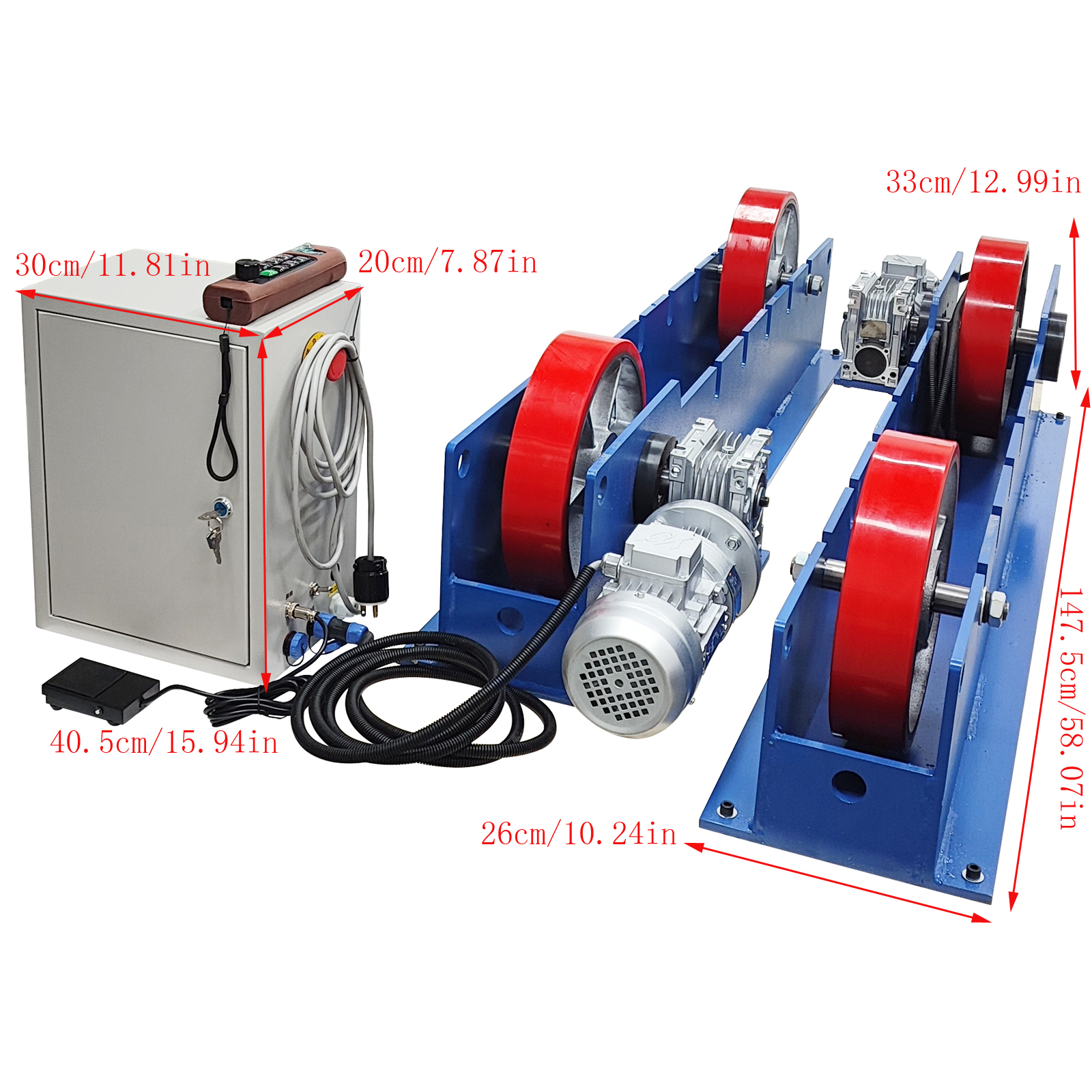

Voltage |

220V Single-phase electricity |

|

Power |

550W*2 |

|

Load Capacity |

3000KG |

|

Speed Range |

100-1000mm/min |

|

Diameter Range |

100-2000mm |

|

Roller Type |

70mm(W)*300mm(D) |

|

|

|

Product

Features |

|

|

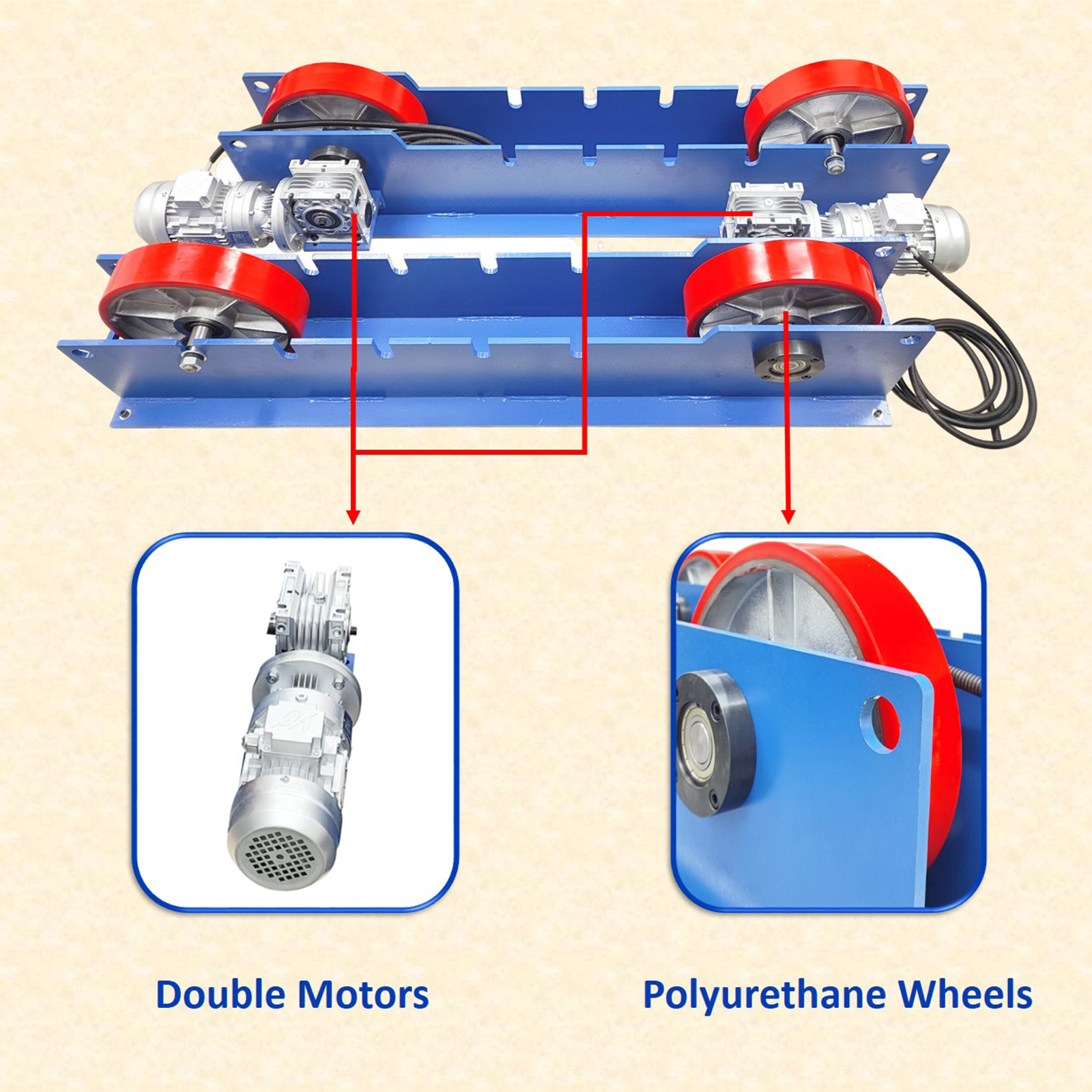

Double Motors

There are two high-quality 550W motors on the roller rack. The

motors can run at different speeds to meet the requirements of

different welding technologies for the rotating speed. The

motors can operate stably to ensure that the roller wheels have

the uniform rotating speed, and the workpieces are prevented

from shaking or slipping. The motors are simple in structure,

low in fault rate and maintenance cost and long in service life.

|

|

Polyurethane Wheels

The four polyurethane wheels are driven by the motors to rotate

synchronously. Due to the polyurethane materials, the wheels can

make soft contact with the workpiece, and the frictional damage

to the workpiece surface can be reduced. The polyurethane wheels

have high friction coefficients, can effectively prevent the

workpiece from slipping and reduce the axial movement in the

welding process. The wheels can achieve shock absorption and

noise reduction and have excellent wear and corrosion resistance

and good insulation performance.

|

|

|

|

Internal Structure

The control box has a compact internal structure, multiple

assemblies are integrated inside the control box for achieving

accurate control over the roller rack in the welding process,

and high precision, high reliability and high compatibility are

well achieved.

|

|

220V

Standard Plug

The plug is equipped with an adapter and suitable for the

standard American power supply. It can be connected to the local

power grid conveniently and directly, It has a certain current

bearing capacity, is resistant to high temperature and wear and

ensures stable power supply.

|

|

|

|

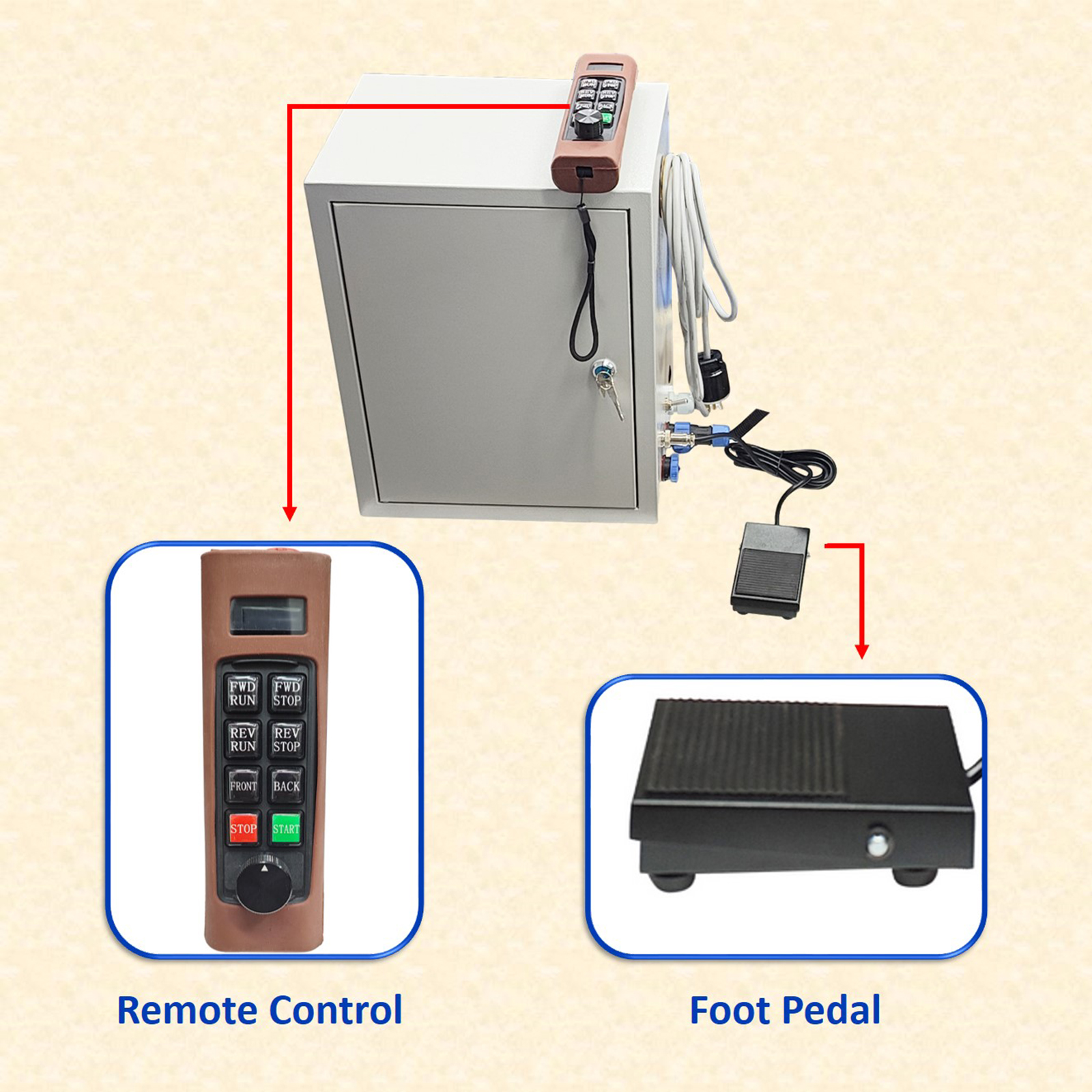

Remote Controller

As a wireless operation device, the remote controller can

remotely control start, stop, speed regulation, forward and

reverse rotation and other operation of the welding roller rack.

It can greatly improve the operating convenience, achieve

accurate speed adjustment and control and enhance the safety,

durability and environmental adaptability.

|

|

Foot

Pedal

As a manual control device, the foot pedal can be used for

effectively controlling the welding roller rack to run. Double

hands of the user can be liberated in the welding process, the

operating efficiency can be improved, the quick response is

achieved, and the foot pedal is safe, reliable and durable, easy

to maintain and low in cost.

|

|

|

Maintenance |

|

Users are responsible for the

proper operation and maintenance of the equipment they use. Some

equipment will quickly become damaged and unsafe if abused or subjected

to improper demands. If equipment is regularly maintained and not

abused, you will get the maximum safety and service performance from

your casters. |

- Do not overload

equipment.

- Do not use overcharged

voltage.

- Do not use hands to stop

the roller when the machine is working.

|

|

Application |

|

The remote control welding roller

rack has the 3000KG load capacity, can be widely applied to different

industries and be matched with various operation machines to achieve

different operation processes, such as plasma cutting, flame cutting,

surface spraying, flange welding and surface polishing. |

|

|

Product

Display |

.jpg) |

.jpg) |

|

Item Number (022815):

1 x 3T Adjustable Welding Turning Roller 220V |

|

|

You can make

order with no worry.

Any concern just feel free to let us know, we'll reply in 24 hours in

normal condition.

Handling Time: Shipping is usually made in 1-3 business days after

payments cleared. Orders are processed from Monday-Friday; Not on the

weekends & public holidays.

Warranty: 6 months' warranty for the machines, not for the consumables.

We stand behind our products all the item, so even if your warranty

period has expired, you can still seek for service or technical support

from us with low cost. |